Bistator single rotor disk type brushless double feed ulternating current electric motor

An AC motor, single-rotor technology, used in electrical components, electromechanical devices, electric components, etc., can solve the problem of low motor power density and power performance index, high motor power density and power performance index, pole number combination and synchronous speed limit and other problems, to achieve the effect of easy realization of structural design, flexible combination of poles, and improved coupling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The motor of the present invention will be described in further detail below in conjunction with the accompanying drawings.

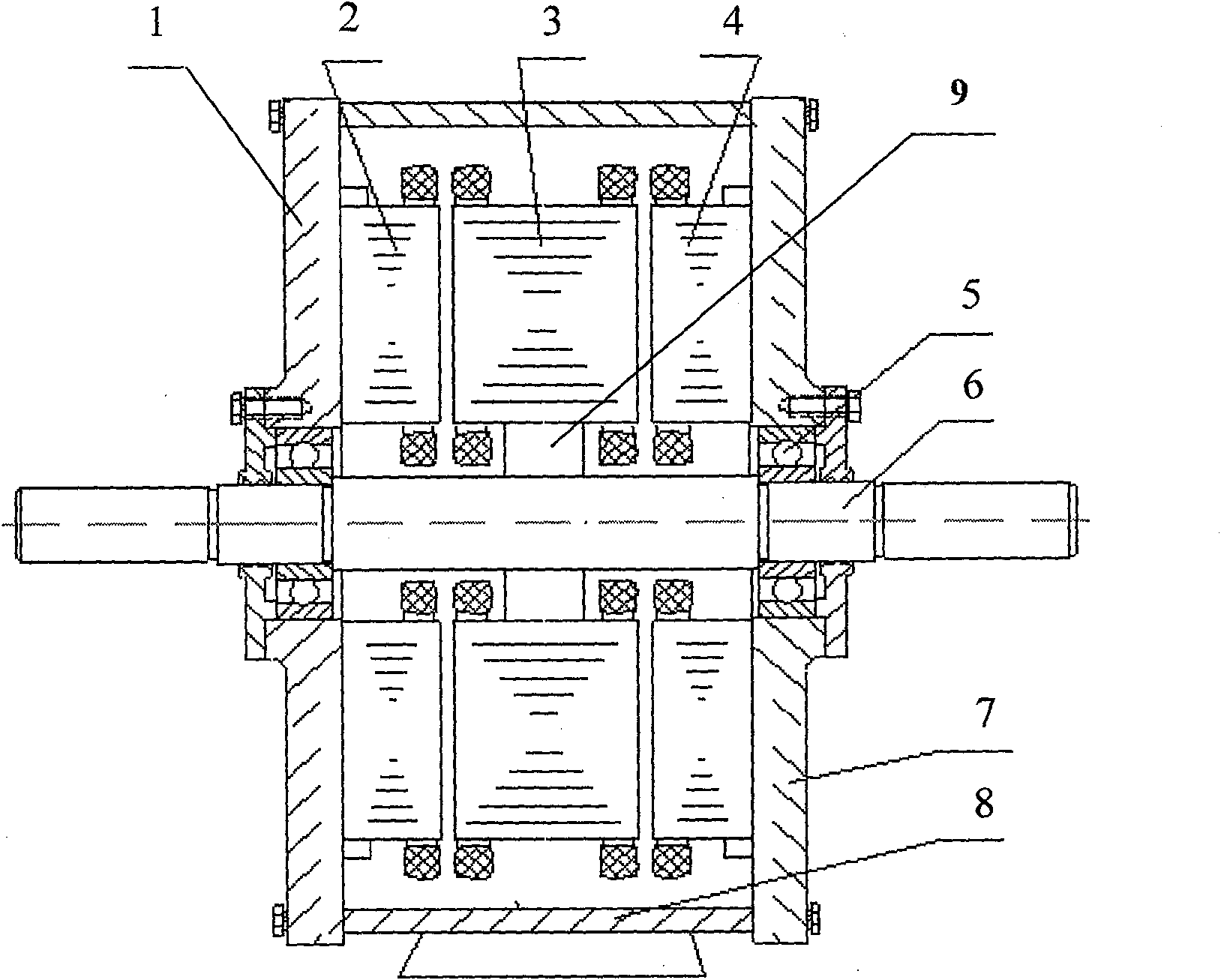

[0011] like figure 1 As shown, the motor of the present invention includes a left end cover 1, a left stator 2, a rotor 3, a right stator 4, a bearing 5, a rotating shaft 6, a right end cover 7, a casing 8, and a rotor support 9. Among them, the left end of the motor shaft 6 is sequentially assembled with a bearing 5 and a left end cover 1 from inside to outside, the left stator 2 is fixed on the left end cover 1, and the right end of the rotating shaft 6 is sequentially assembled with a bearing 5 and a right end cover 7 from inside to outside, and the right stator 4 is fixed. On the right end cover 7, a rotor bracket 9, a rotor 3 and a casing 8 are sequentially assembled in the middle of the rotating shaft 6 along the vertical direction from inside to outside. The left end cover 1, the left stator 2, the casing 8, the right end cover 7, the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com