Ratchet batch

A ratchet and gear technology, applied in the field of ratchet batches, can solve problems such as large minimum rotation angle, inability to loosen screws, and adjustment of forward and reverse directions, etc., and achieve the effect of small rotation angle of ratchet, low cost and few parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

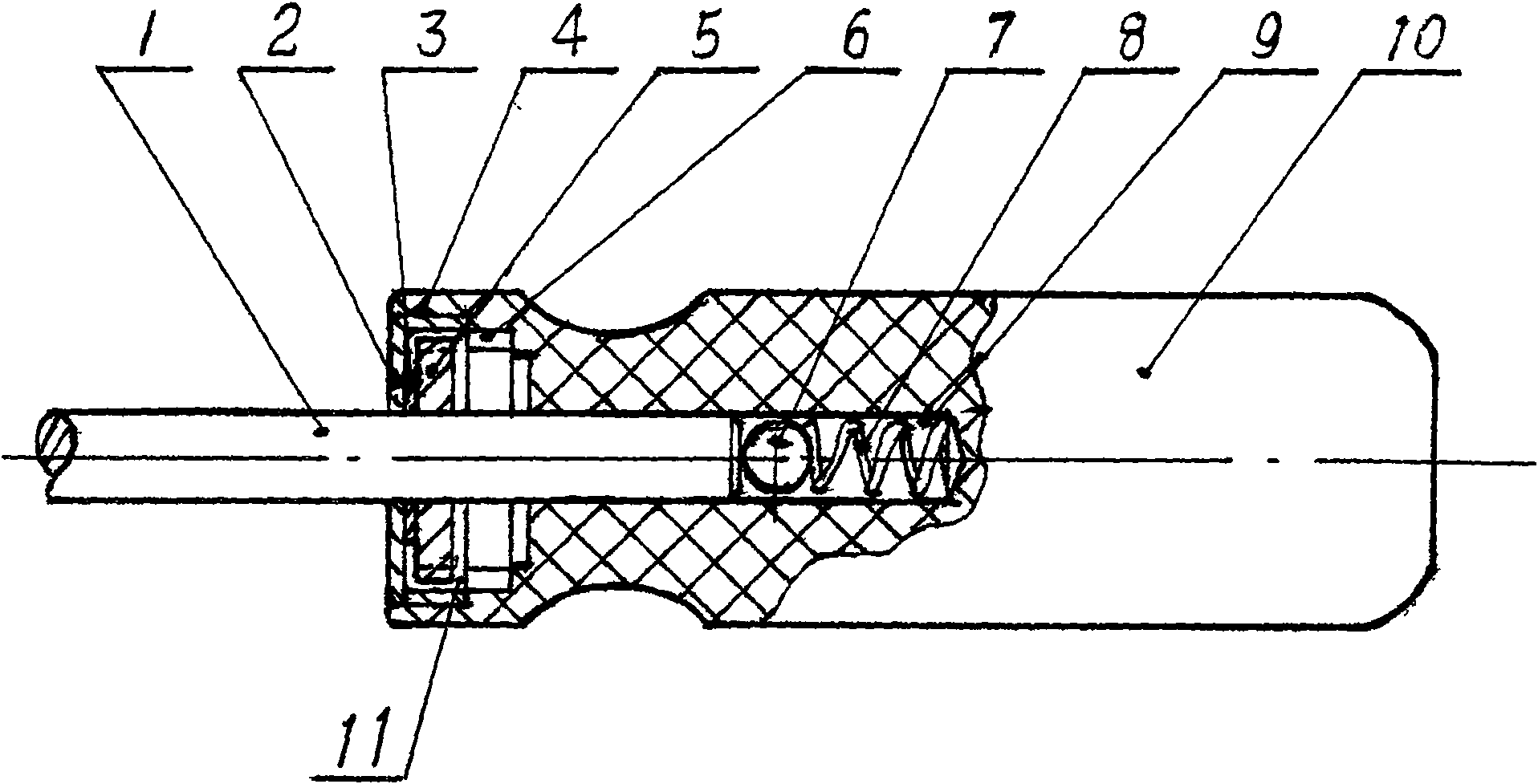

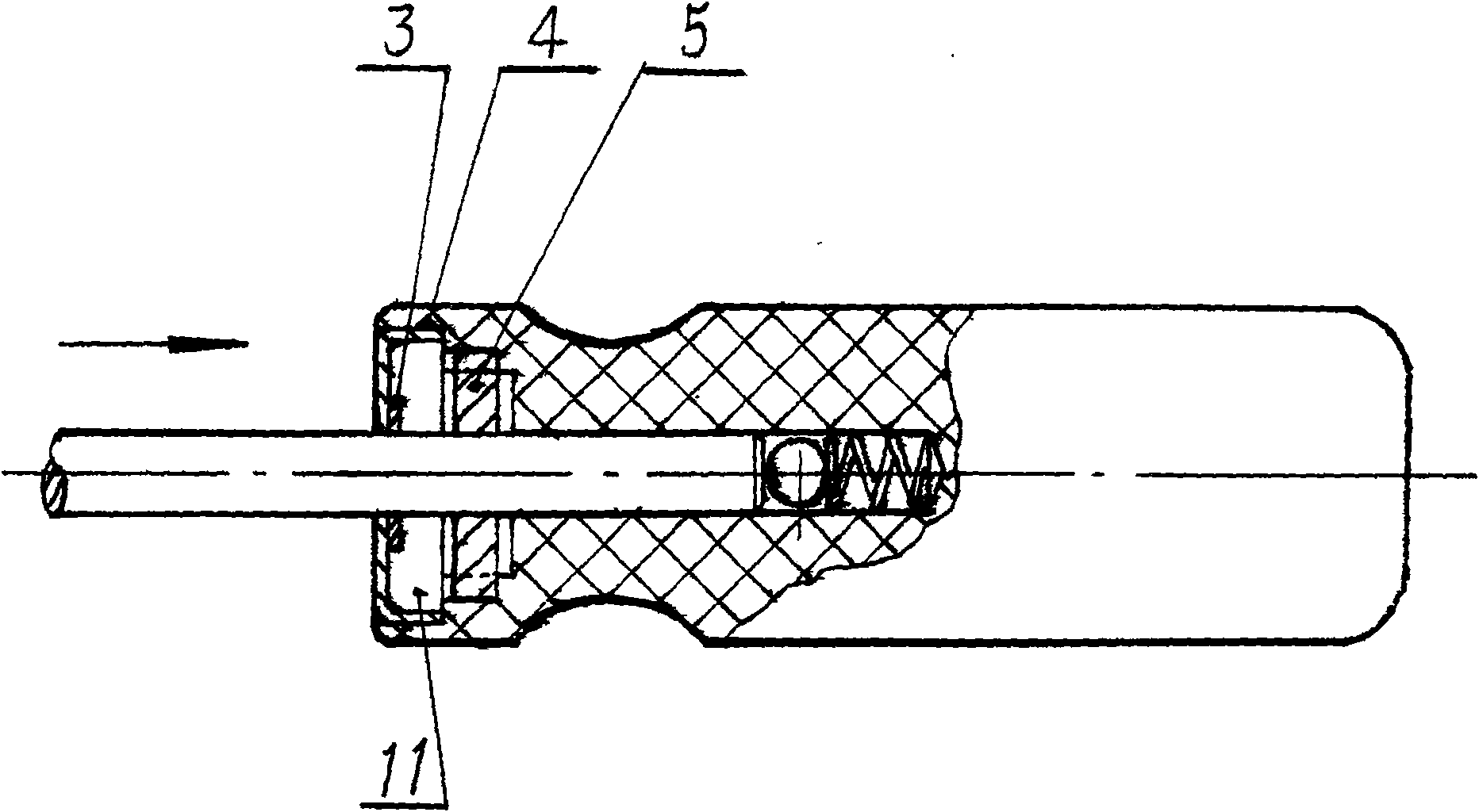

[0015] Such as figure 1 , figure 2 As shown, a gear 5 is provided on the batch rod 1, and the gear 5 is connected with the batch rod 1 as a whole. An end face of the handle 10 is provided with a circular hole 4, and on the inner wall of the circular hole 4 that is greater than a gear thickness from the aperture There is an annular protruding inner ring gear 6 that is fully meshed with each tooth of the gear 5, and a cylindrical cavity 11 is formed between the inner ring gear 6 and the round hole, the gear 5 is located in the round hole 4, and It can reciprocate between the inner ring gear 6 of the round hole 4 and the cylindrical cavity 11; one end of the batch lever 1 is inserted into the round guide hole 9 provided at the inner end of the inner ring gear 6, and the bottom of the round guide hole 9 is in contact with the batch A spring 8 and a steel ball 7 are provided between the end faces of the rod 1; a cover 2 is provided at the mouth of the round hole 4, and a gasket 3...

Embodiment 2

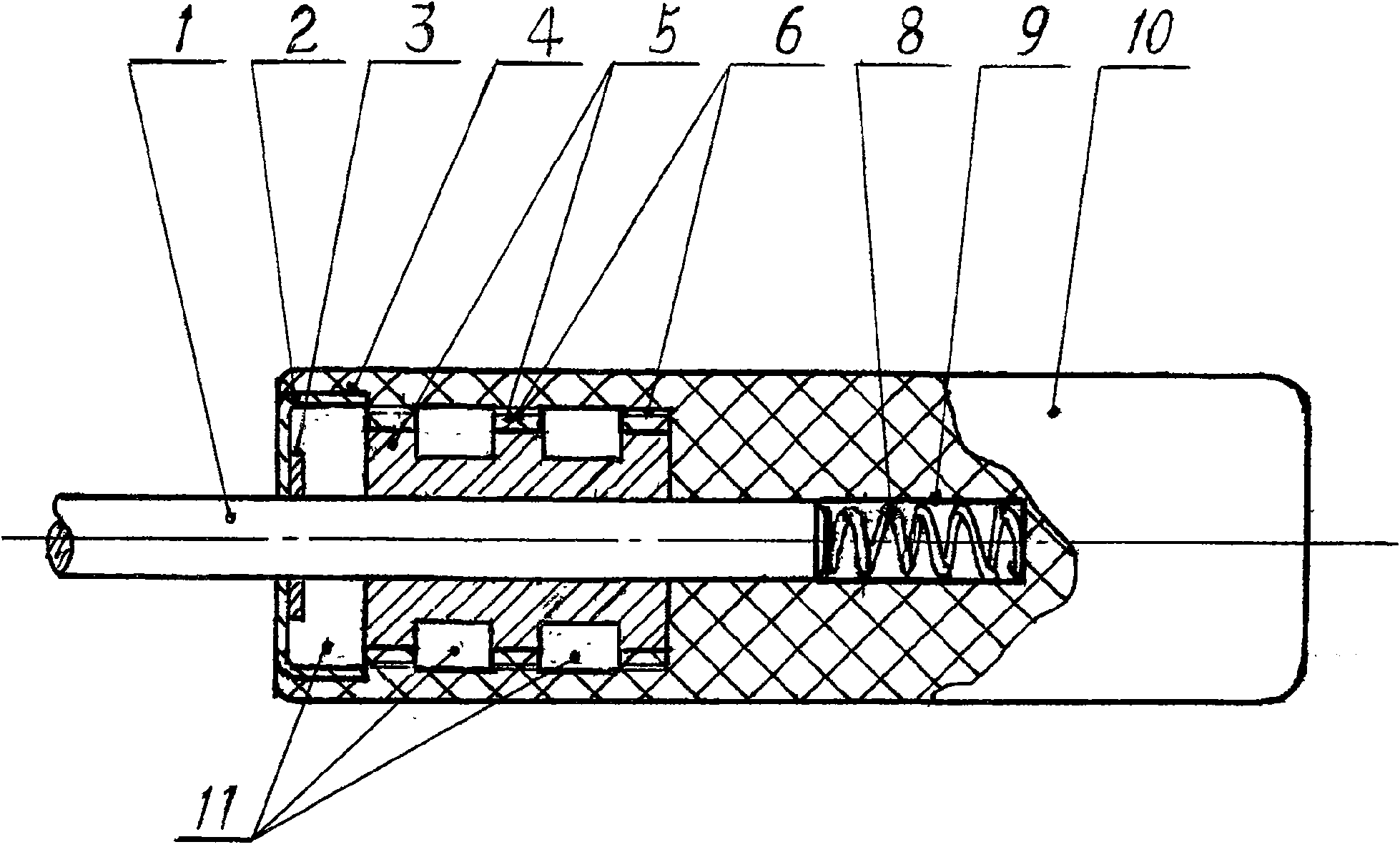

[0019] Such as image 3 , Figure 4 As shown, three identical gears 5 are arranged on the batch rod 1, the intervals between adjacent gears are equal, and the gears and the batch rod 1 are connected as a whole. An end face of the handle 10 is provided with a round hole 4; from a position greater than one gear thickness from the hole, three ring-shaped protrusions are provided on the inner wall of the round hole 4, and each tooth of the gear 5 is fully meshed with each other. Ring gear 6, the interval between adjacent ring gears 6 is the same as the gear interval, and three cylindrical cavities 11 are formed between adjacent ring gears 6 and between the ring gear 6 and the round orifice. Three gears 5 It is located in the round hole 4, and can reciprocate between the inner ring gear 6 of the round hole 4 and the cylindrical cavity 11; one end of the rod 1 is inserted into the circular guide hole 9 provided at the inner end of the inner ring gear 6, and the round A spring 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com