Single motor front and rear axle drive electric tractor

A technology for electric tractors, front and rear axles, applied in the direction of electrical components, electromechanical devices, vehicle components, etc., can solve the problems of reduced turning radius, waste of electric energy, shortened frame, etc., to achieve reduced turning radius, reduced transformation costs, and reduced The effect of turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

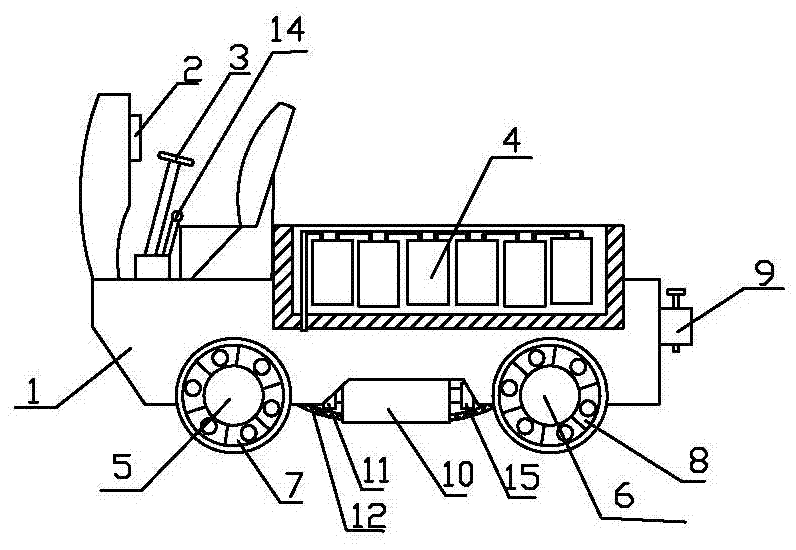

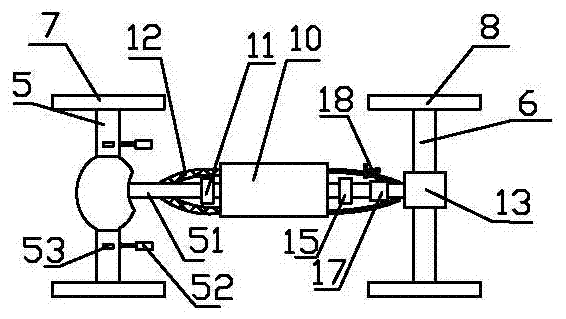

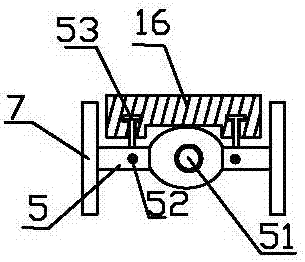

[0020] Example: figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 An example of the invention is given. refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 Make the invention.

[0021] The single-motor front and rear axles drive the electric tractor, including a car body 1, a control device 2, a steering wheel 3, a battery pack 4, a front axle 5, a rear axle 6, a front wheel 7, a rear wheel 8, a traction object connection device 9, and a control device 2. Set on the inner side of the front fender of the vehicle body 1. A display screen and control buttons are provided on the control device 2. The steering wheel 3 is located between the control device 2 and the vehicle seat. The battery pack 4 is installed in the compartment of the vehicle body 1. , the front wheels 7 are installed at both ends of the front axle 5, the rear wheels 8 are installed at both ends of the rear axle 6, and the traction conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com