Light dispersing element, backlight module and LCD device

A liquid crystal display and backlight module technology, applied in the direction of diffusion elements, instruments, optics, etc., can solve the problems of increasing the production cost of the backlight module and insufficient brightness of the surface light source, and achieve the effect of improving the display quality and saving the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail in conjunction with the accompanying drawings.

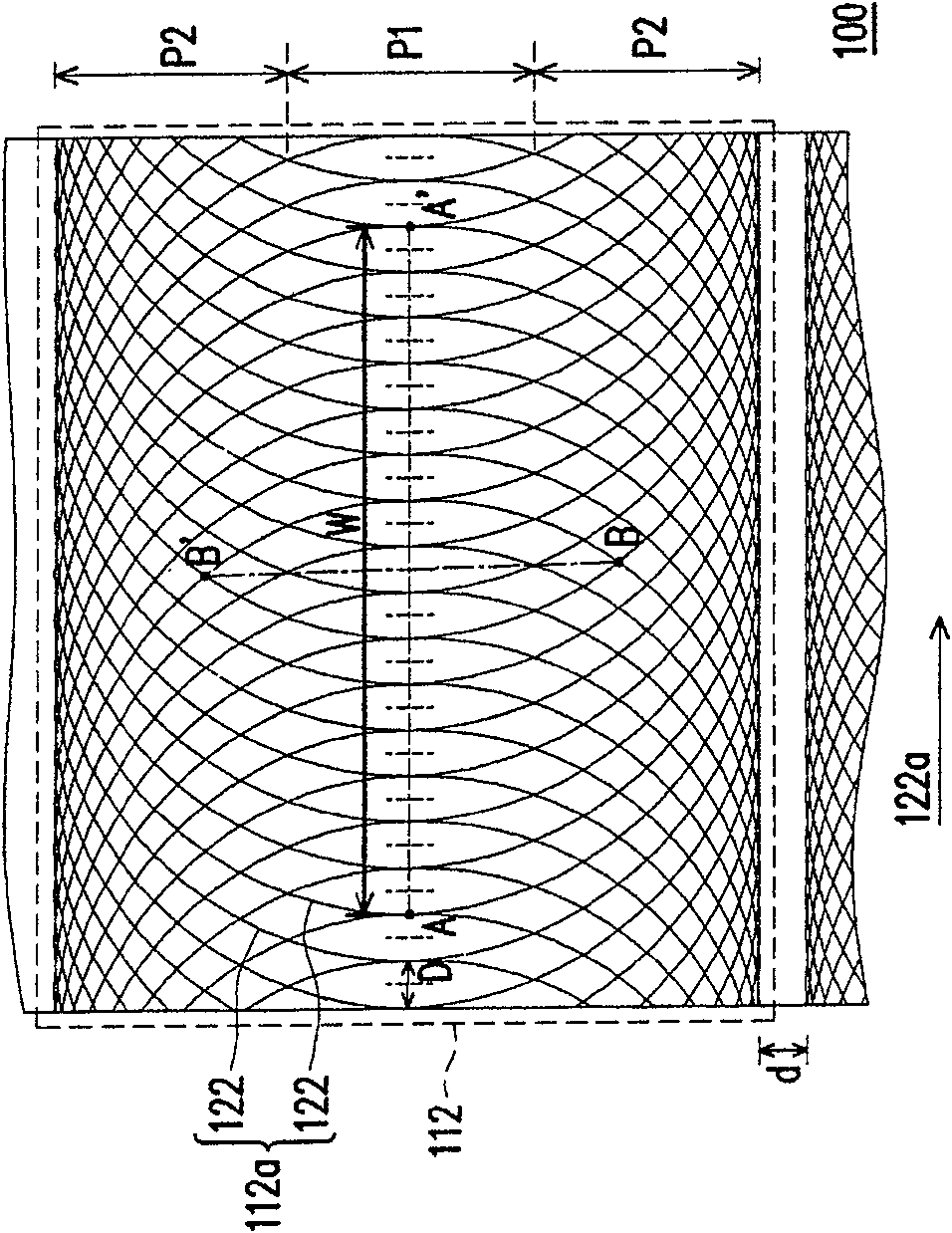

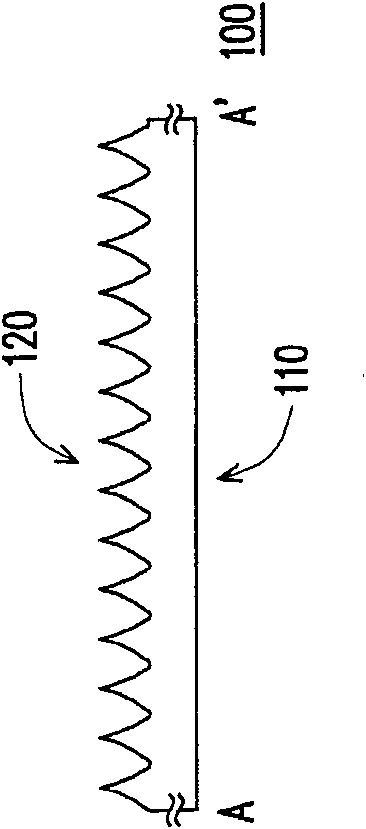

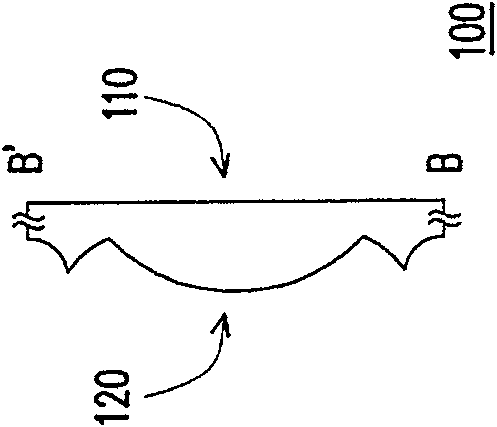

[0052] Figure 1A A partial top view showing a light diffusing element according to an embodiment of the present invention, Figure 1B for along Figure 1A The schematic cross-sectional view of the light diffusion element shown by the AA' section line of , and Figure 1C for along Figure 1A The schematic cross-sectional view of the light diffusing element shown by the BB' section line. Please also refer to Figure 1A , Figure 1B and Figure 1C , the light diffusing element 100 of this embodiment has a light incident surface 110 and a light exit surface 120 . There is at least one light scattering pattern 112 on the light emitting surface 120 .

[0053] In this embodiment, the track of the light scattering pattern 112 is a continuous curve 112a, so the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com