Hanging method using C-beam piercing core hanging large-scale electric motor and C-beam structure

A hoisting method and technology for large motors, which are used in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as horizontal installation of large motors with insufficient space, and achieve safe and reliable core-piercing process, good economic benefits and social benefits. Benefit, the effect of ensuring the position of the centerline of the motor rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

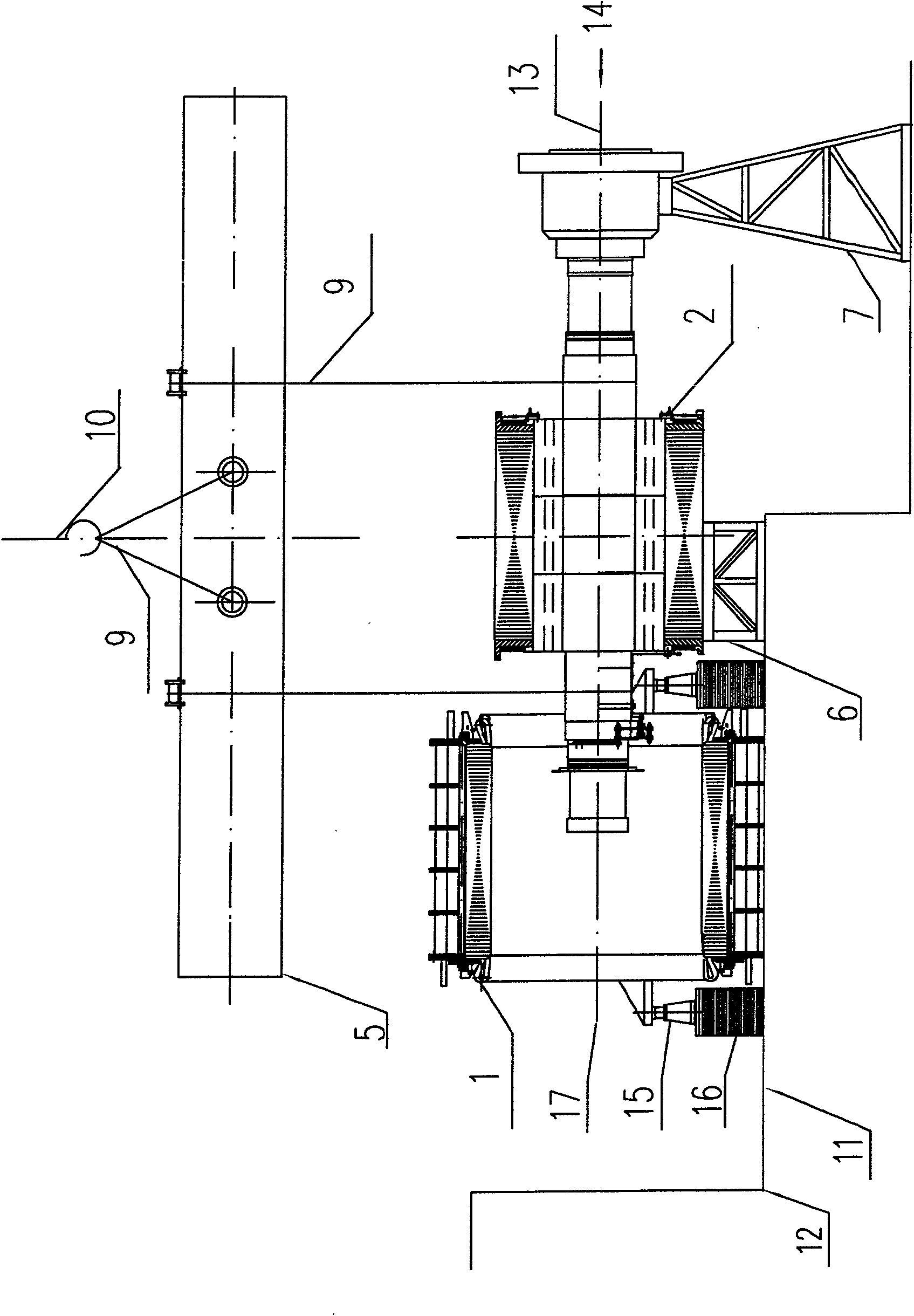

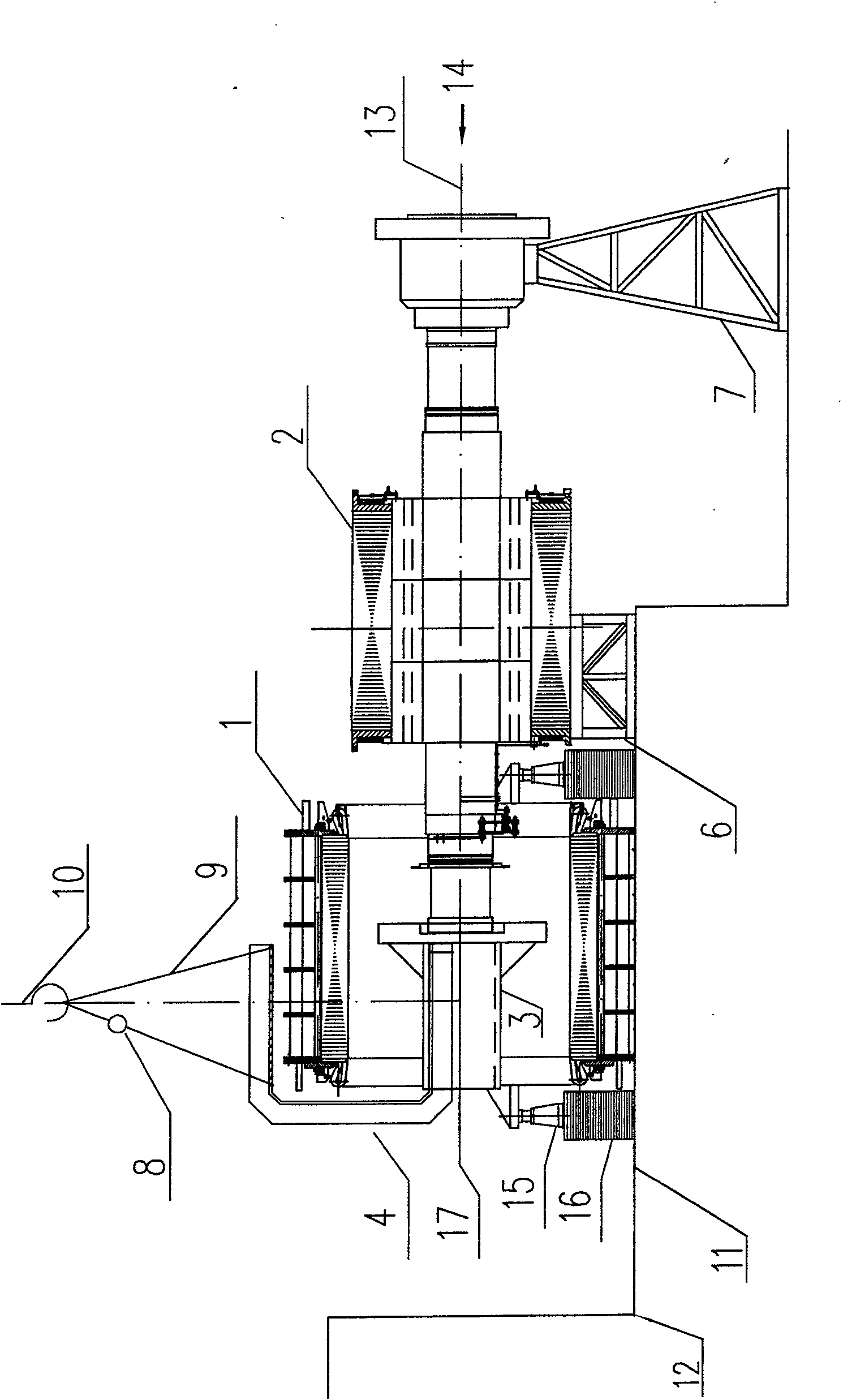

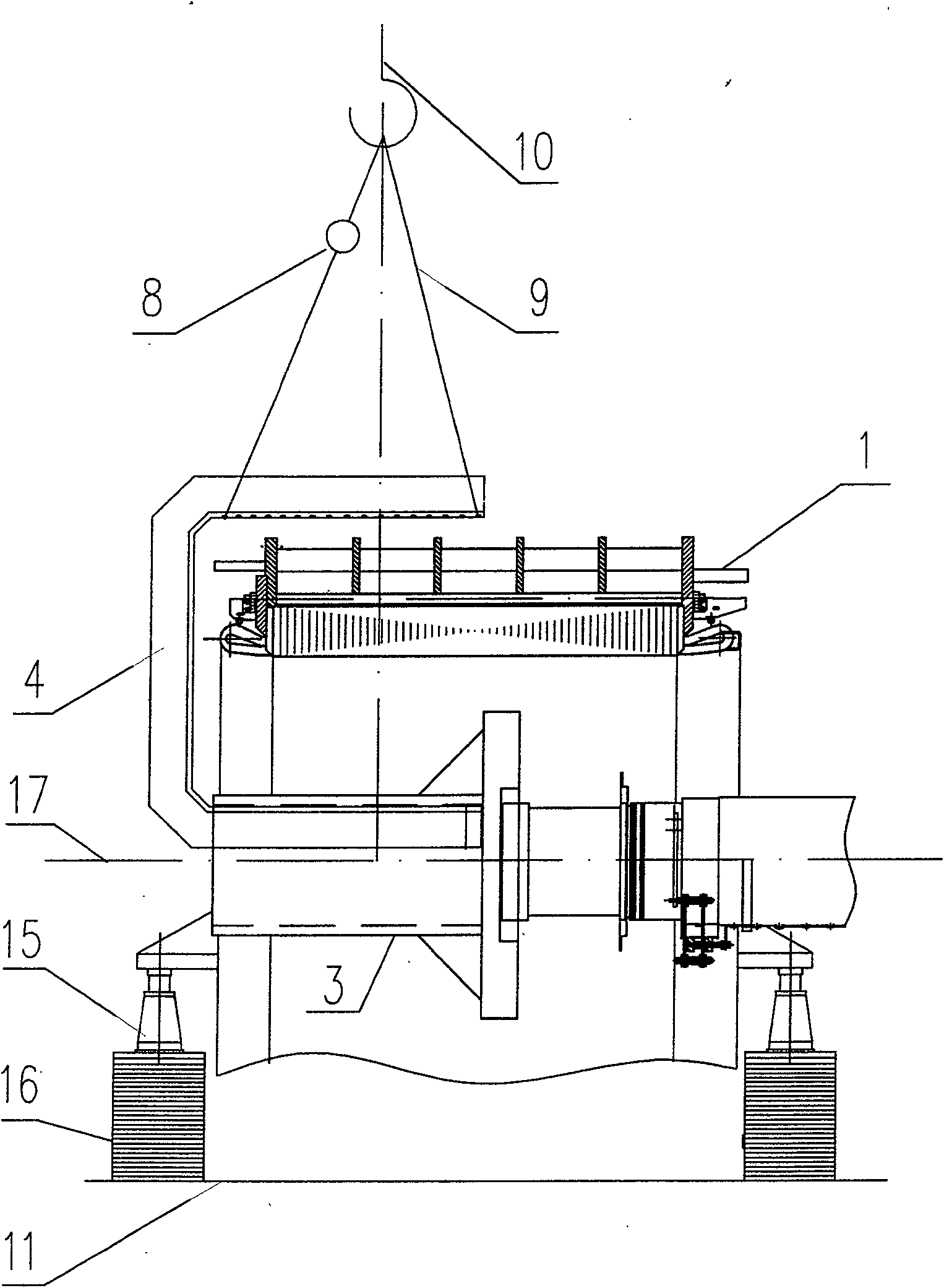

[0022] The hoisting method of the present invention using a C-shaped beam to hoist a large motor through the core will be further described in detail below in conjunction with the accompanying drawings.

[0023] The C-shaped beam involved in the hoisting method of the present invention, such as Figure 3-1 , Figure 3-2 , Figure 3-3 with Figure 3-4 As shown, the C-shaped beam is welded by steel plates to form a hollow box-shaped structure with equal cross-section. The inner side of the C-shaped beam is provided with a stiffener plate. In order to be more stable and reliable during the hoisting process, a The ribs are provided with arc grooves to facilitate chain rewinding operations. The distance between the inner sides of the upper and lower arms of the C-shaped beam is slightly greater than the maximum radial dimension of the upper part of the motor stator, and the length (referring to the net length) of the upper and lower arms of the C-shaped beam is equal to or sligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com