Vertical type lathe servo motor assembly connecting device and connecting method thereof

A servo motor and vertical lathe technology, applied in electromechanical devices, feeding devices, manufacturing motor generators, etc., can solve the problem that the mounting bolts of the servo motor assembly are easy to loosen, the transmission accuracy cannot be guaranteed, and the measurement and calculation workload Large and other problems, to achieve the effect of simple and easy operation, quality assurance, and reduced maintenance costs for the renovation and installation work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

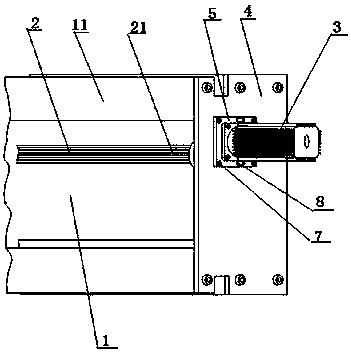

[0034] Example 1, please query figure 1 , figure 2 , image 3 , Figure 7 , Figure 8 , a vertical lathe servo motor assembly connection device according to Embodiment 1 of the present invention, including a frame 1, a transmission shaft 2, a servo motor assembly 3, a mounting plate 4 and an adjustment plate 5, and the transmission shaft 2 is connected to a vertical lathe The tool rest of the lathe and transmits feed power for it, the mounting plate 4 is fixed on the driving end 21 of the drive shaft 2 of the frame 1, the servo motor assembly 3 is fixed on the adjustment plate 5, the servo motor assembly The output shaft 31 of 3 is connected with the transmission shaft 2 through the gear transmission 6, and the mounting plate 4 and the adjustment plate 5 are all provided with through holes for the output shaft 31 of the servo motor assembly 3 to pass through; the mounting plate 4 It is fixedly connected with the adjustment plate 5 through the bolt 7 provided in the instal...

Embodiment 2

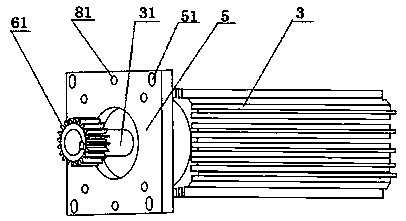

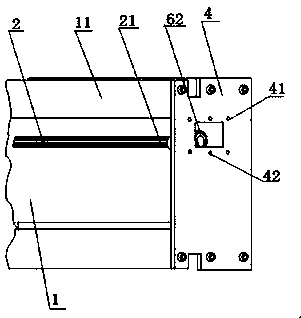

[0049] Example 2, please query Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , a vertical lathe servo motor assembly connection device according to Embodiment 2 of the present invention, including a frame 1, a transmission shaft 2, a servo motor assembly 3, a mounting plate 4 and an adjustment plate 5, and the transmission shaft 2 is connected to a vertical lathe The tool rest of the lathe and transmits feed power for it, the mounting plate 4 is fixed on the driving end 21 of the drive shaft 2 of the frame 1, the servo motor assembly 3 is fixed on the adjustment plate 5, the servo motor assembly The output shaft 31 of 3 is connected with the transmission shaft 2 through the gear transmission 6, and the mounting plate 4 and the adjustment plate 5 are all provided with through holes for the output shaft 31 of the servo motor assembly 3 to pass through; the mounting plate 4 It is fixedly connected with the adjustment plate 5 through the bolt 7 provided in the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com