Aid, equipment and method for detecting bearing outer ring height

A bearing outer ring, height detection technology, applied in the field of measurement, can solve the problems of reduced measurement efficiency, influence measurement accuracy, height error, etc., to achieve the effect of high measurement efficiency and accuracy, improve detection accuracy, and avoid errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, the specific implementation manner of the present invention will be further described in detail in conjunction with the accompanying drawings.

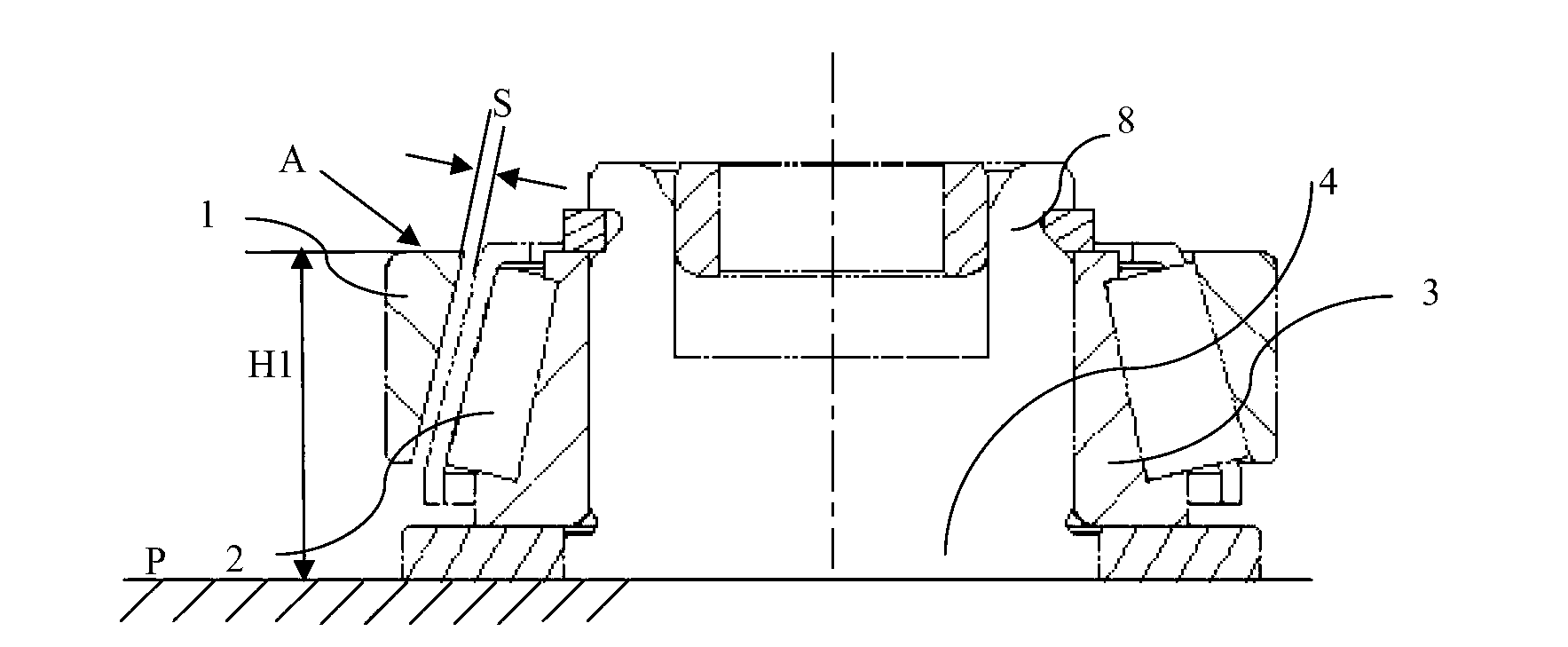

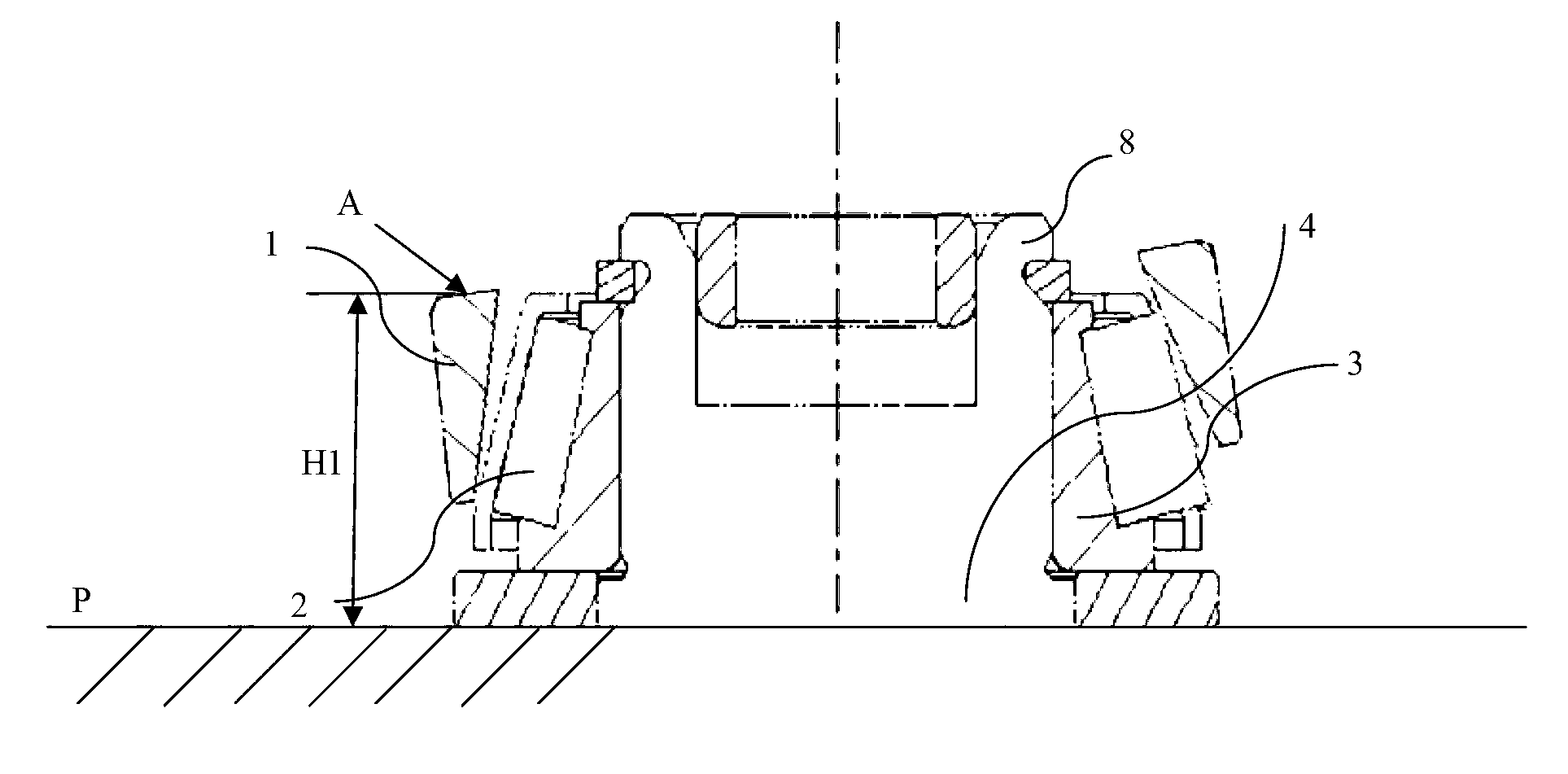

[0028] refer to figure 1 , After the bearing is installed on the shaft 4, it is necessary to measure the height H1 of the outer ring of the bearing relative to a reference plane P to select a shim to adjust the axial clearance. In the prior art, generally, multiple groups of symmetrical points A are selected (only one point is shown in the figure), measured with a height vernier caliper, and then averaged. The more measurement points, the more accurate the measurement value, but the lower the measurement efficiency.

[0029] to combine figure 1 , figure 2 , because there is a gap S between the bearing outer ring 1, the roller 2 and the bearing inner ring 3, when measuring point A, when the measuring claw of the height vernier caliper (not shown) presses on point A, the bearing outer ring will A few flips occur so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com