Method for producing a heterogeneous, especially multi-coloured sheet-shaped structure, mould and sheet-shaped structure

A sheet-like structure, non-homogeneous technology, used in household appliances, other household appliances, applications, etc., can solve the problems of not suitable for large sheet-like structure parts, difficult to manipulate extension parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

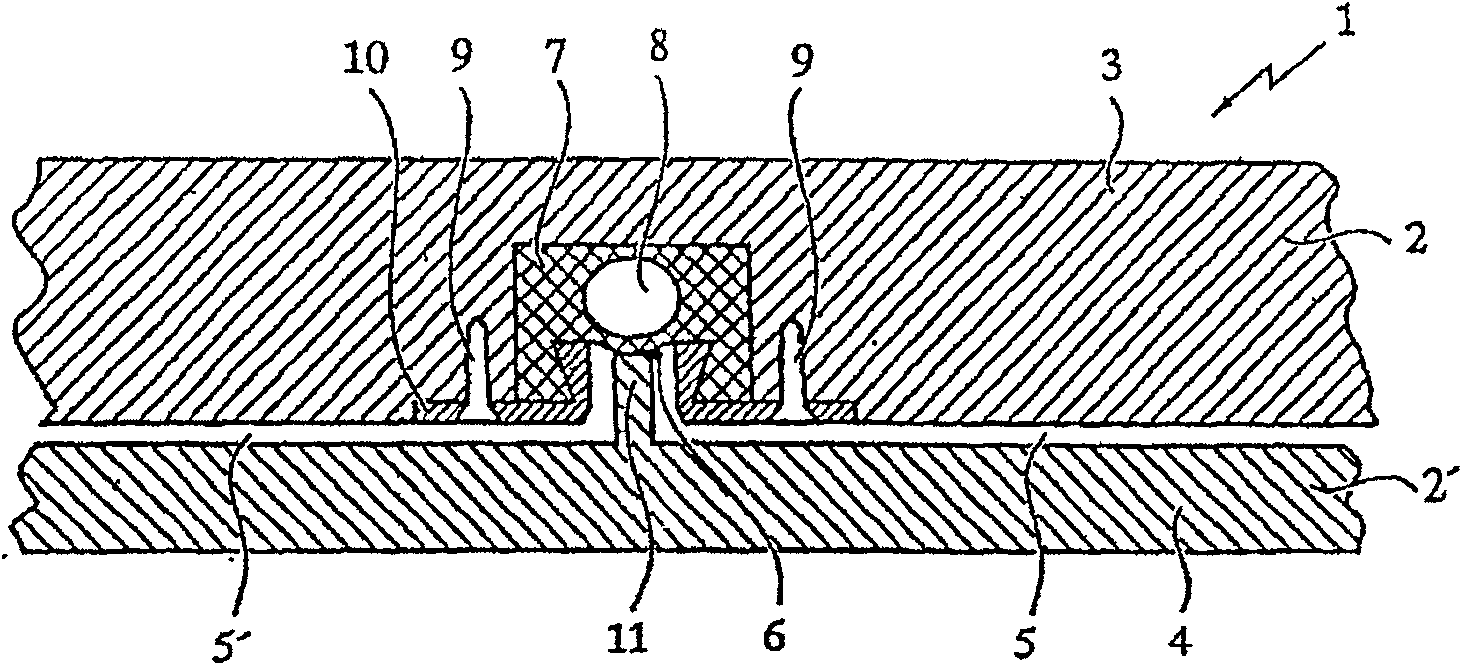

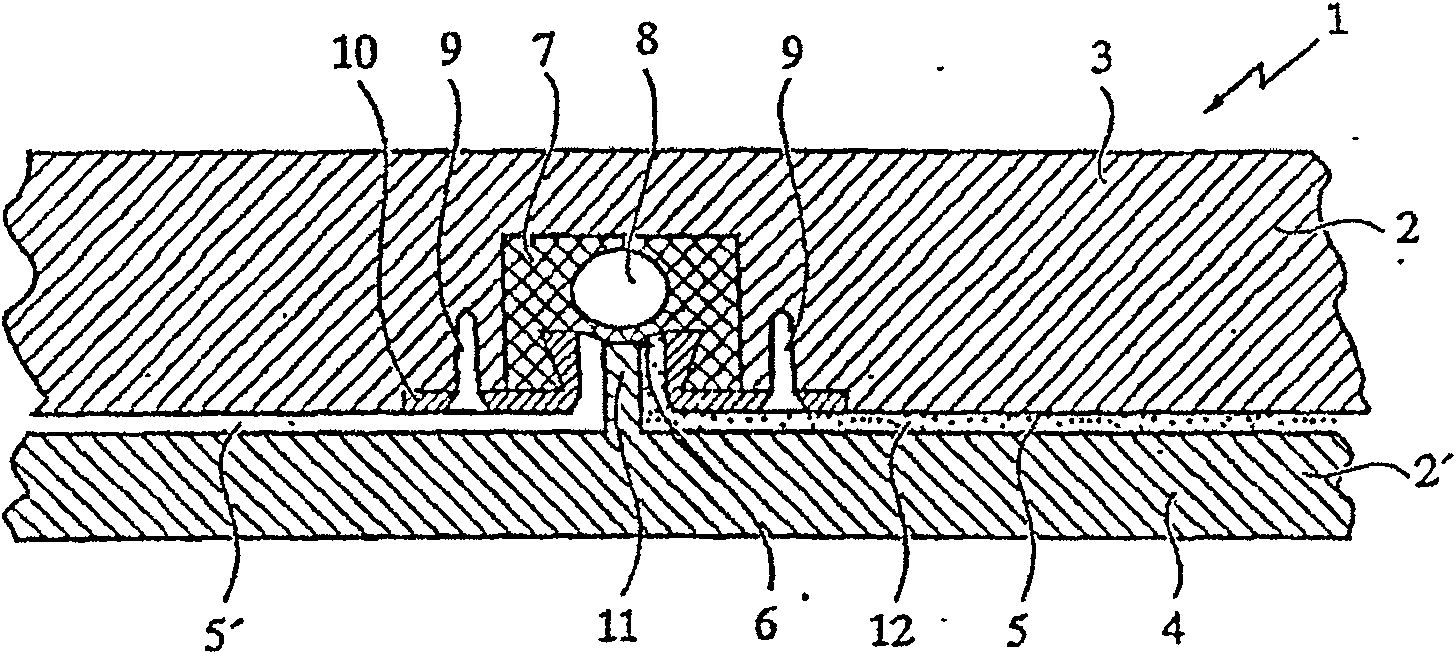

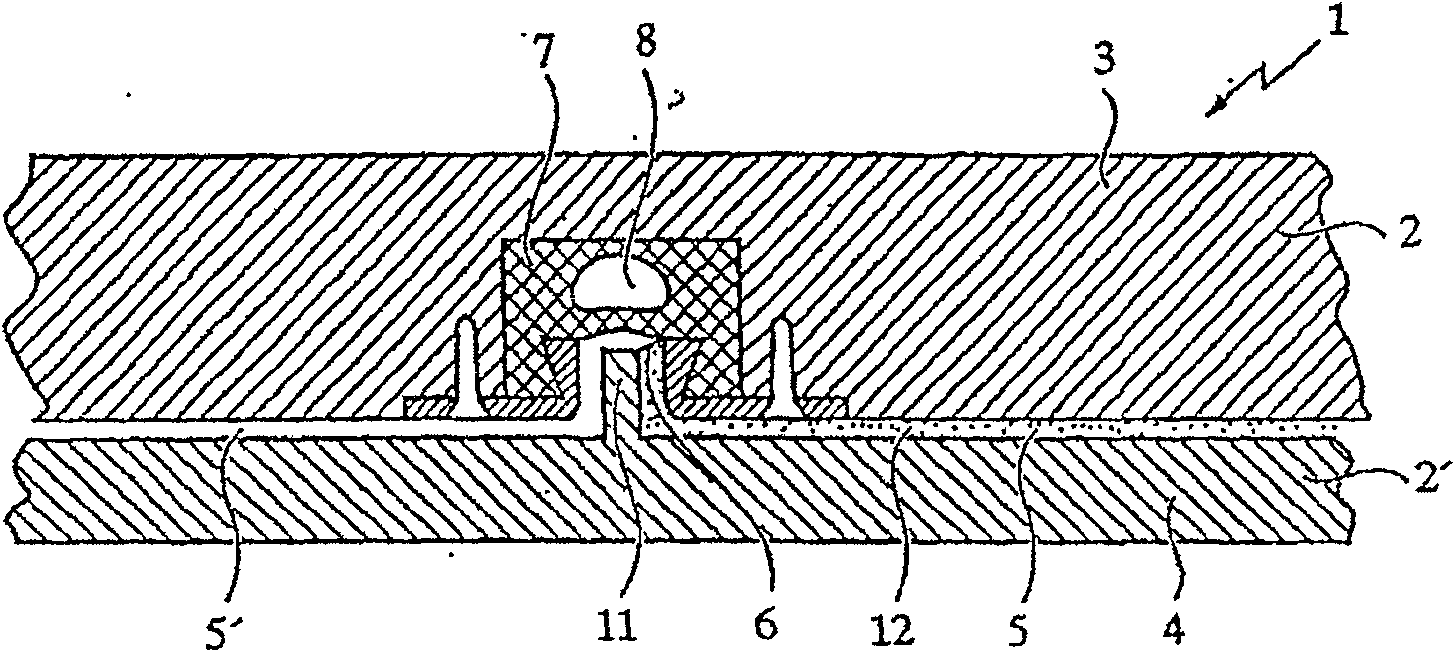

[0018] Figures 1a to 1d The mold 1 shown comprises a first mold part 2 formed by an upper mold 3 and a second mold part 2' formed by a lower mold 4. The upper mold 3 and the lower mold 4 can be displaced relative to each other, and when they are located Figure 1a In the shown use position, a first cavity 5 and a second cavity 5' are formed. These cavities extending in two dimensions can be filled with different free-flowing polymeric materials by means of an injection molding unit (not shown) and are suitable for the manufacture of sheet-like structures which have, relative to their length and width, Very small thickness. The cavity does not have to be formed in a planar manner, but can have a curved profile for making a complex shaped decorative skin.

[0019] The upper mold 3 is provided with a tubular sealing member 7 along the interface 6 between adjacent cavities 5, 5', wherein the hollow space 8 can be filled with compressed gas after the mold parts 2, 2' are closed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com