Method for packing soft edge spring mattress

A packaging method and mattress technology, applied in packaging, transportation and packaging, vacuum/special atmosphere packaging, etc., can solve the problems of bulky, inconvenient packaging and transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

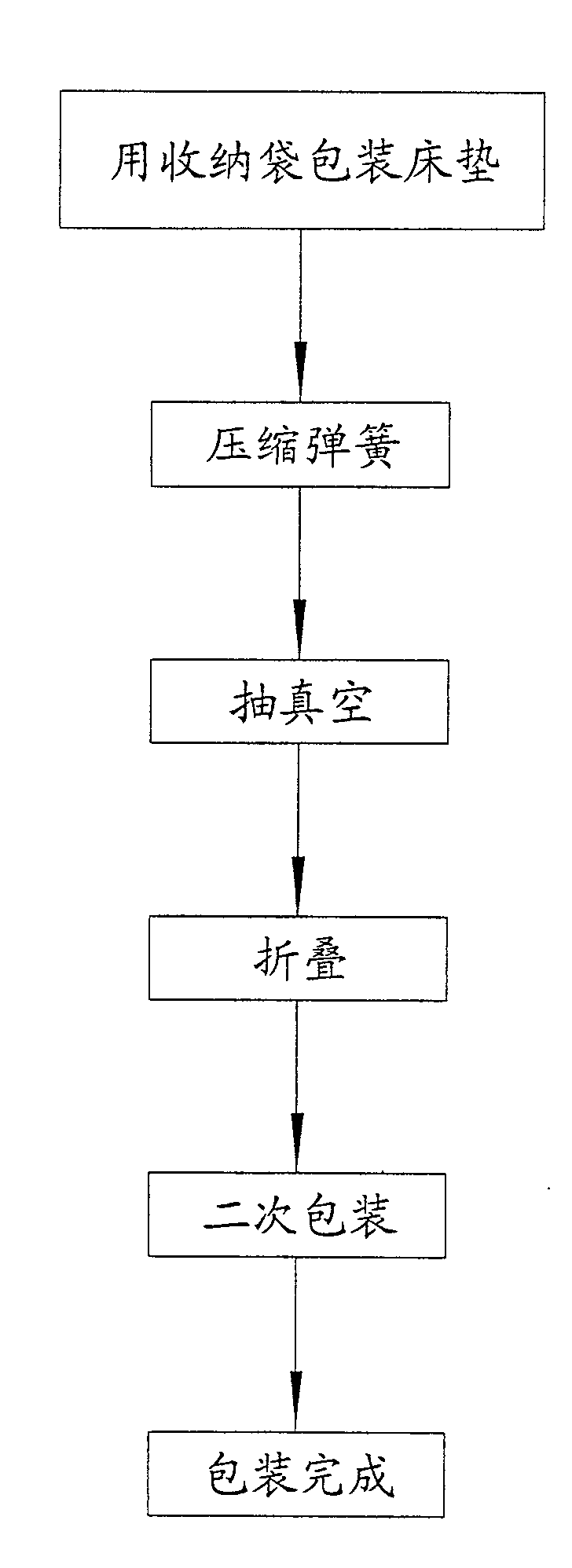

[0023] see image 3 As shown, the inventors aimed at figure 2 Block diagram of the packaging process developed for the soft side spring mattress shown and for all soft side spring mattresses.

[0024] The first step is to cooperate Figure 4 Shown, spring mattress is packed in the storage bag 5 earlier.

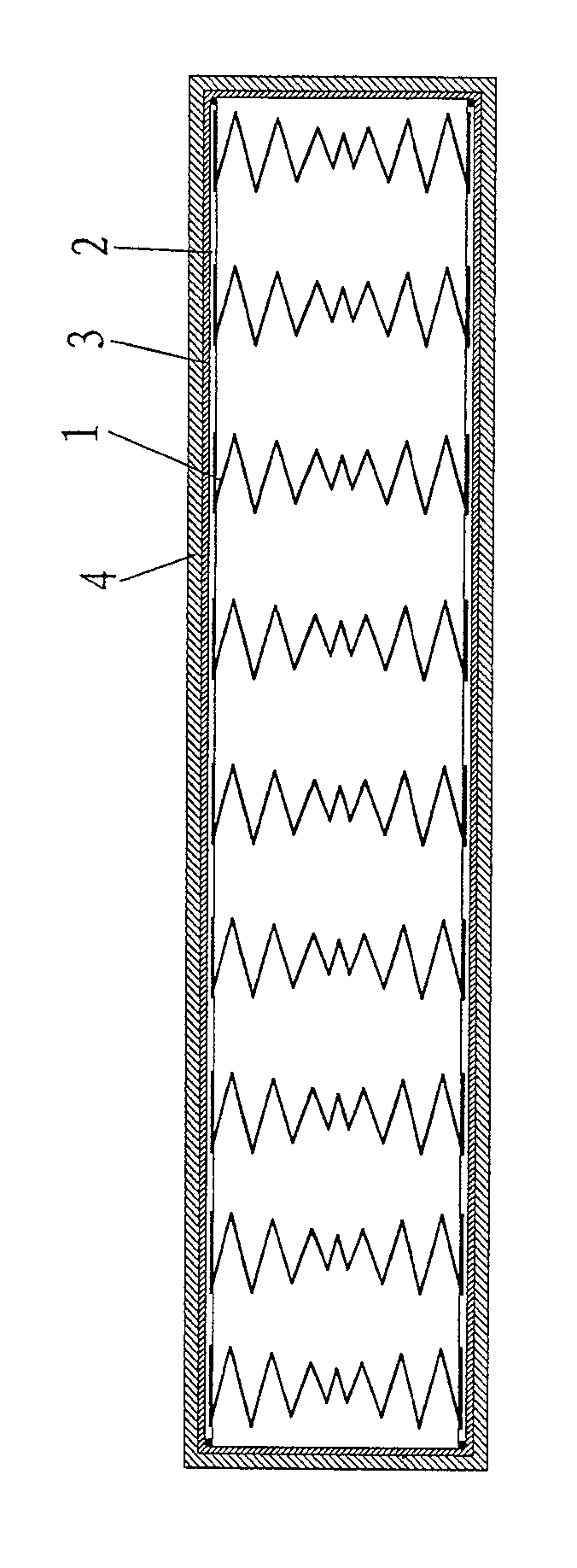

[0025] The second step, cooperate Figure 5 As shown, the spring 1 is compressed along the centerline direction of the spring 1 by means of mechanical equipment to reduce the height of the spring 1 as much as possible.

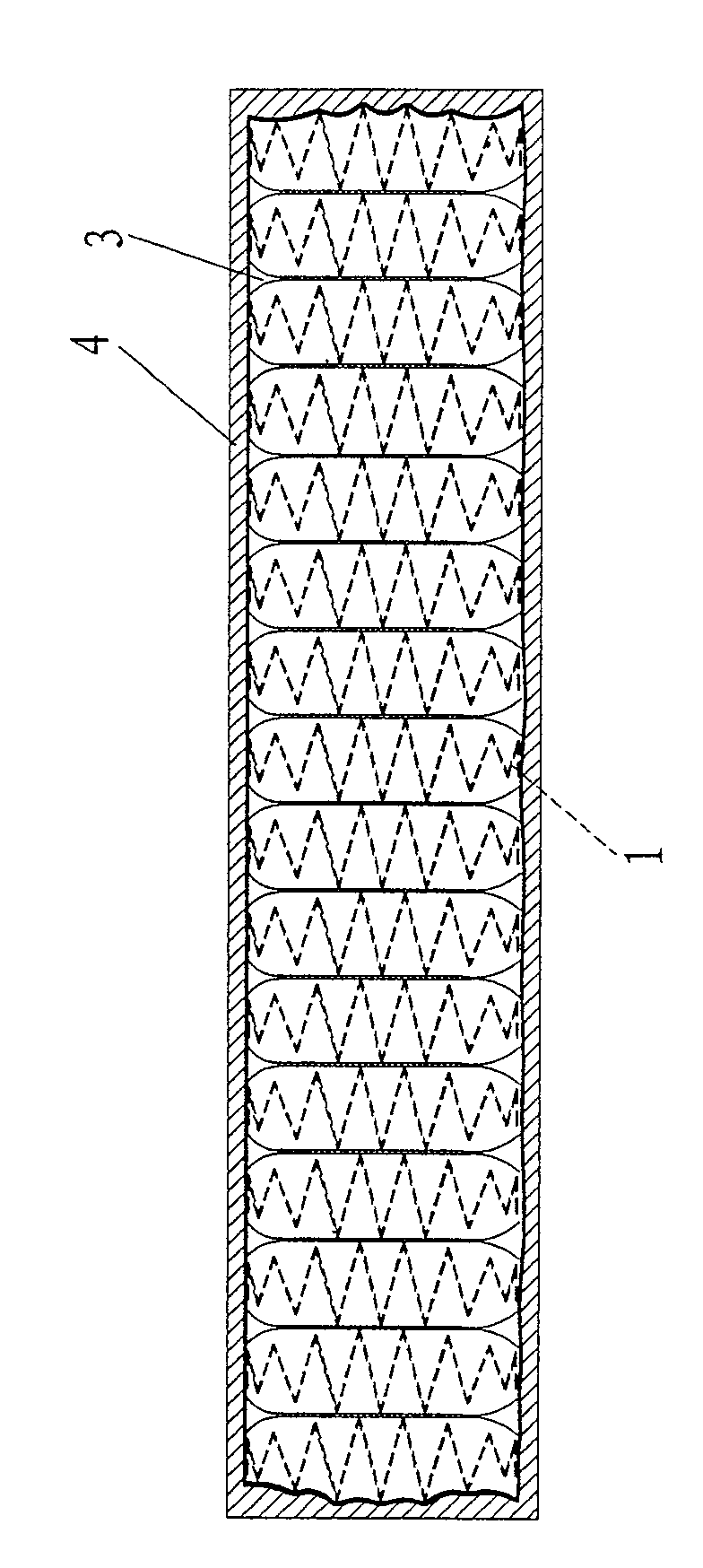

[0026] The third step is to cooperate Figure 6 As shown, the storage bag 5 is evacuated again, and the air in the storage bag 5 and the sponge 4 is extracted, so that the storage bag 5 and the spring mattress are reduced into sheets.

[0027] The fourth step, cooperate Figure 7 As shown, according to the needs of packaging, transportation, etc., the Figure 6 The sheet-like storage bag 5 and spring mattress are folded to the required size.

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com