Low-noise fanner

A fan and low-noise technology, applied in the field of low-noise fans and low-noise fans, can solve the problem that the size and noise level cannot meet the comprehensive performance requirements of the propulsion motor at the same time, and the air volume, total pressure and efficiency cannot meet the requirements of the propulsion at the same time. The ventilation and cooling requirements of the motor and the failure to meet the maintenance requirements of the ventilation and cooling system of the marine propulsion motor have achieved the effect of remarkable technical effect, simple structure and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

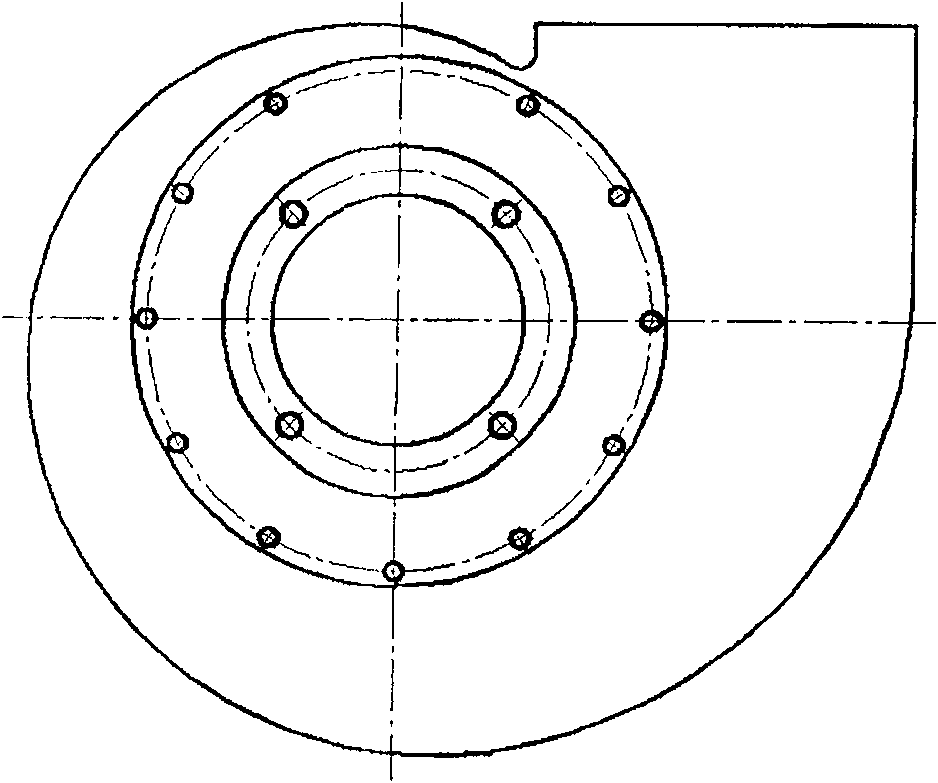

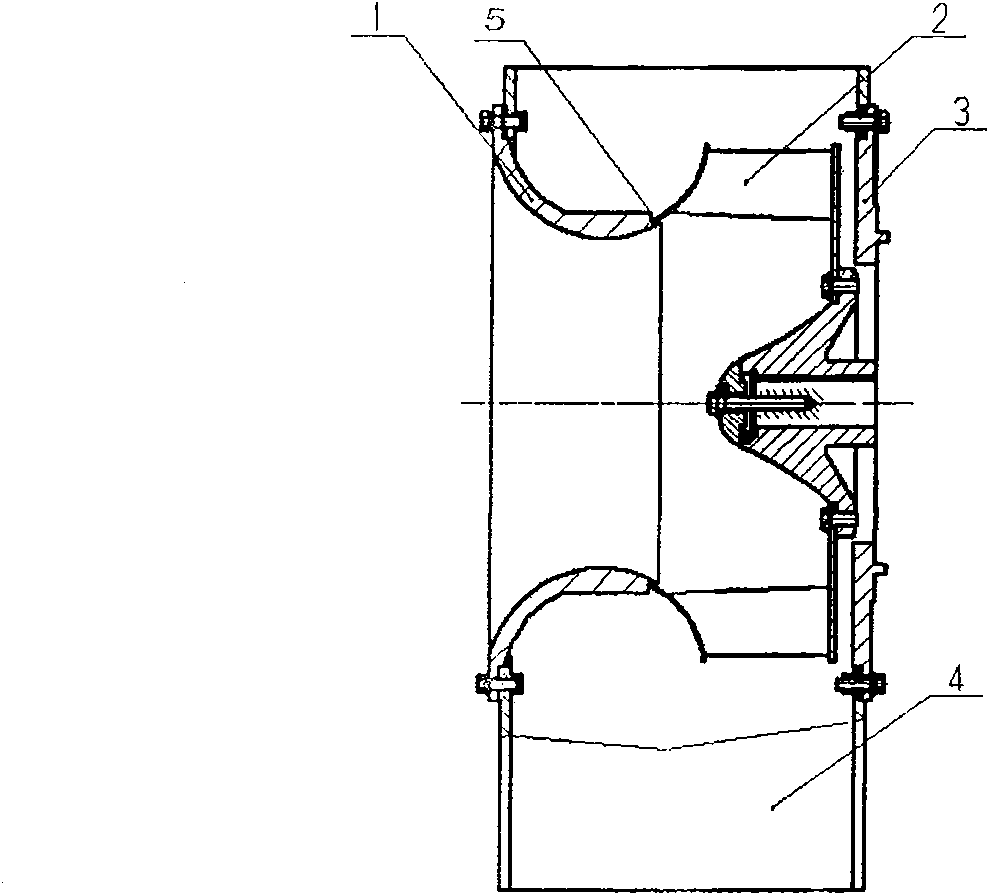

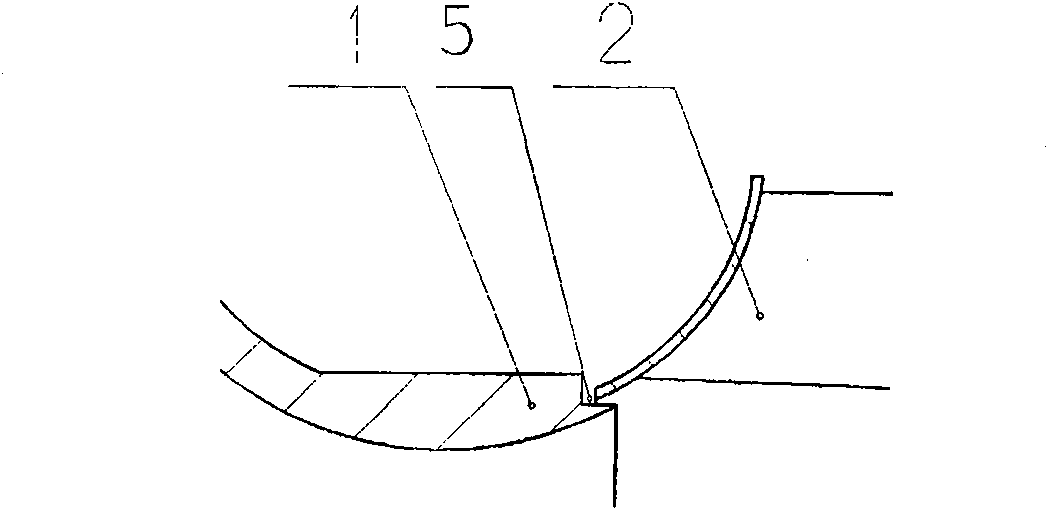

[0026] Embodiment 1: as Figure 1-7 As shown, it is a low-noise fan, which has an air inlet 1, an impeller 2, and a volute 4; there is a maintenance flange 3 on the motor side of the fan; the maintenance flange 3 and the air inlet 1 are respectively connected to the volute The shell 4 is positioned and fixedly connected with a seam; the air inlet 1 is arc-shaped and streamlined to improve the pressure coefficient and overall efficiency of the fan. 1 There is an embedded dynamic fit groove 5 at the place where it matches the tuyere of the impeller 2. The dynamic fit gap is the radial gap and axial gap at the groove 5; the radial gap is less than or equal to 2 mm on one side, and the is 1.5 mm, and the axial gap is less than or equal to 6 mm, which is selected as 4 mm; the air inlet 1 is cast from an aluminum alloy to form an integral part, and is produced by casting aluminum alloy, which has good manufacturability and light weight; the thickness of the air inlet 1 is 15-25 mm,...

Embodiment 2

[0027] Embodiment 2: The difference from the above embodiment is that the diameter parameter of the air inlet 1 streamlined arc is 80 mm; the radial gap at the groove 5 is 1 mm on one side, and the axial gap is 2 mm; the air inlet 1 The thickness of the volute is 15 millimeters, and the thickness of the steel plate of the volute 4 is 5 millimeters. The fixed connections between the air inlets 1 and the volute 4 are bolt connections.

Embodiment 3

[0028] Embodiment 3: The difference from the above embodiment is that the diameter parameter of the streamlined arc of the air inlet 1 is 150 mm; the radial gap at the groove 5 is 2 mm on one side, and the axial gap is 6 mm; the air inlet 1 The thickness of the volute is 25 millimeters; the thickness of the steel plate of the volute 4 is 16 millimeters. The fixed connection between the air inlet 1 and the volute 4 is screw connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com