Flexible multi-layer circuit board producing method

A manufacturing method and circuit board technology, applied in the direction of multi-layer circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of shrinking the available area of flexible multi-layer circuit boards, increasing short circuits or open circuits, and complex circuit layouts, and achieving improved performance. The effect of line connection stability, low production cost and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

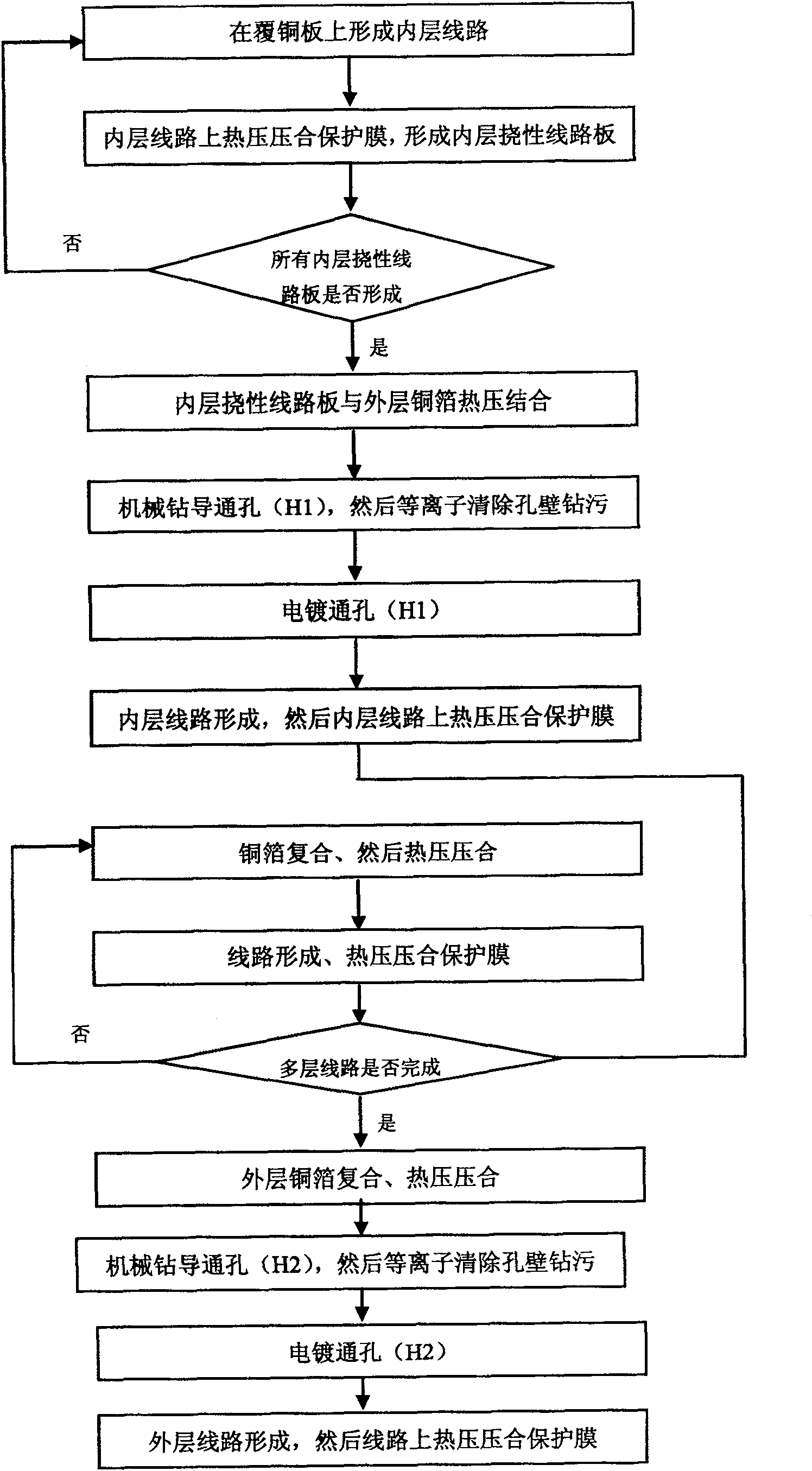

[0018] Described in the detailed description is a method of manufacturing a flexible multilayer circuit board.

[0019] Four-layer flexible multilayer circuit board, including blind holes H1 connecting three-layer circuit boards and through-holes H2 penetrating four-layer circuit boards, Figure 2 to Figure 9 Blind hole H1 and through hole H2 are marked in . The position of the blind hole H1 is determined according to the wiring requirements of the circuit board in practical applications.

[0020] The method for manufacturing the four-layer flexible multilayer circuit board will be described below.

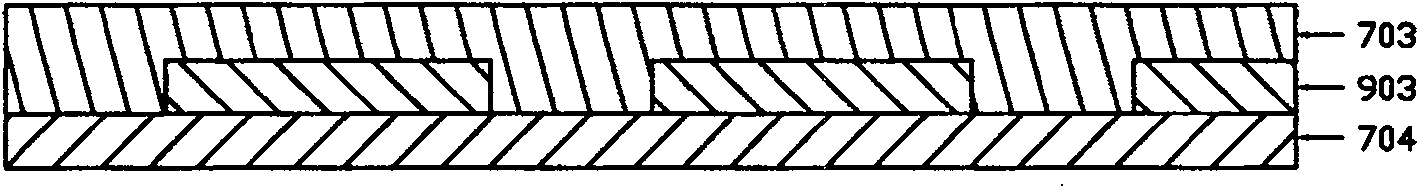

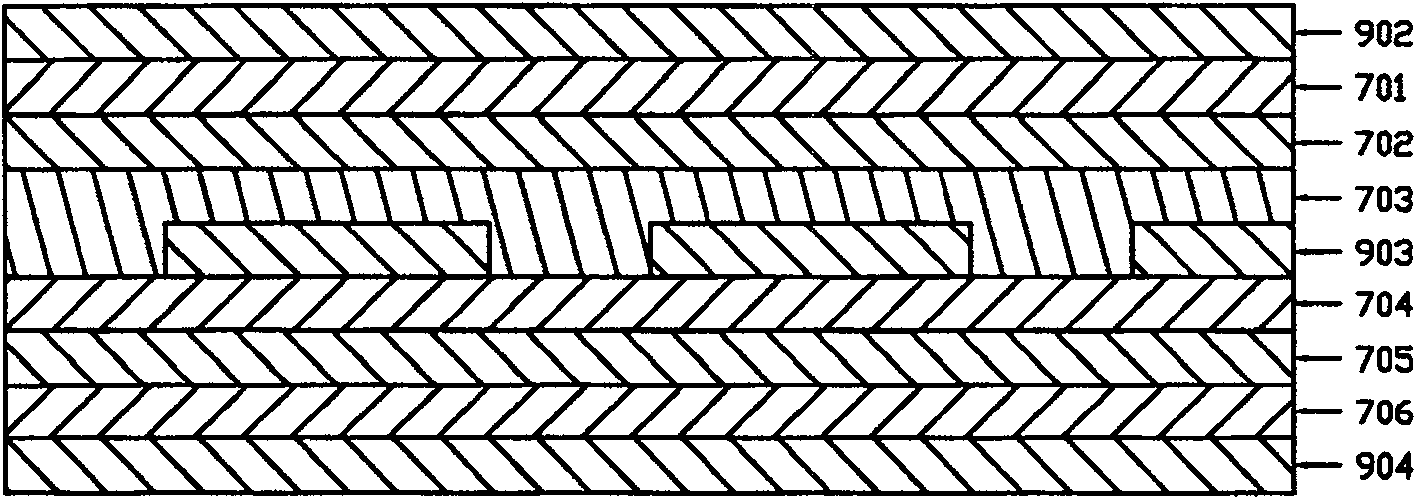

[0021] see Figure 2 to Figure 10 , first at figure 2 In the step of forming and laminating a protective film for an inner layer circuit, protective layers 703 and 704 are respectively laminated on both sides of copper foil 903 . exist image 3 In the process, one prepreg film is pasted on both sides of the protective film 703, 704 and the base material 702, 704 (polyimide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com