Automatic woven tape winding machine

A coiling machine and webbing technology, which is applied in textile, knitting, and strip winding, can solve the problems of increasing labor intensity, reducing efficiency, and increasing equipment investment, so as to save manpower and material investment, improve work efficiency, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

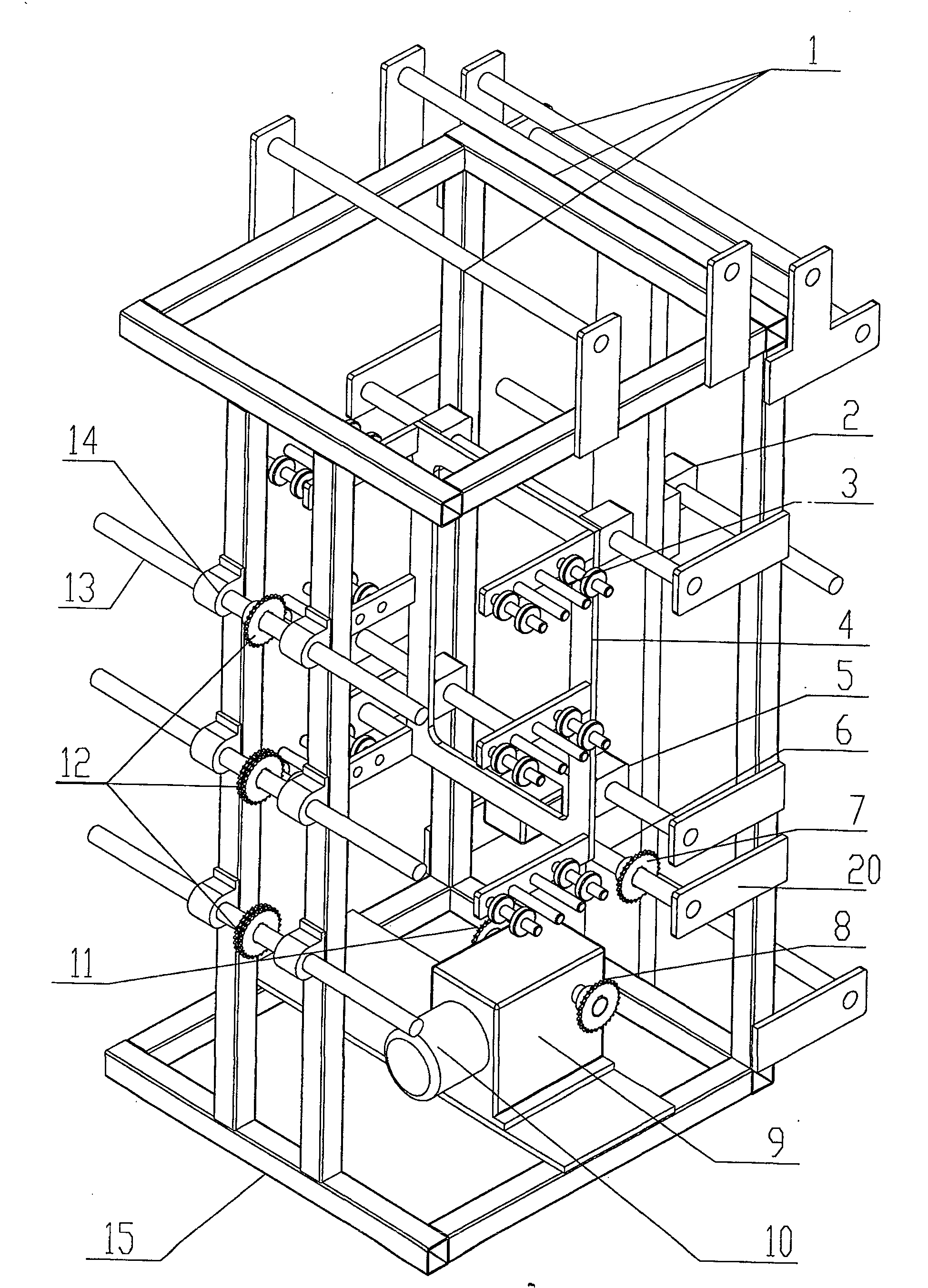

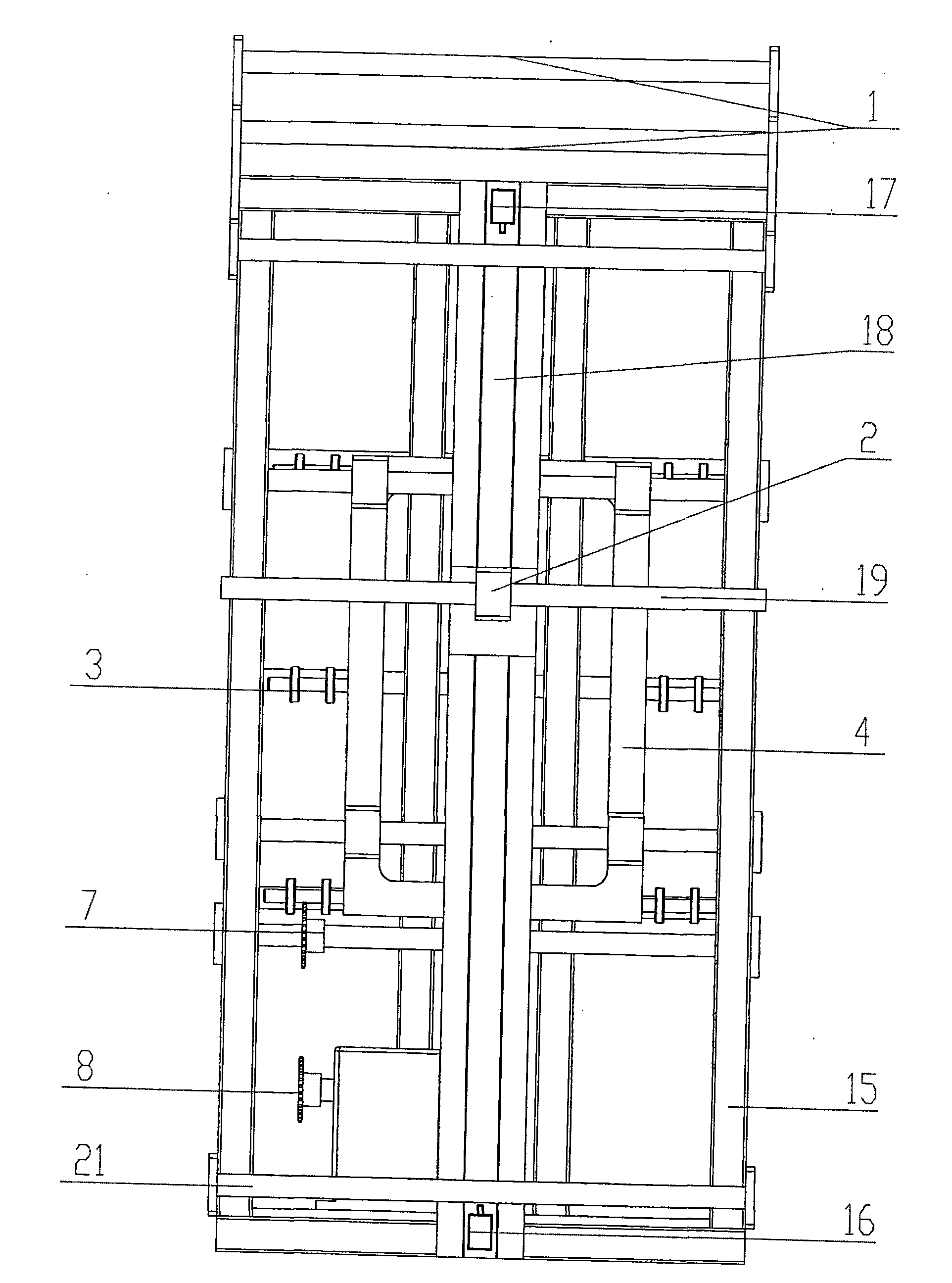

[0011] The present invention is described in further detail below in conjunction with accompanying drawing:

[0012] like figure 1 , 2 As shown, the main body frame 15 of this invention is welded by 40 square tubes, and three groups of round rods 13 with threads at both ends are installed on the front of the main body frame 15, and the round rods 13 are fixed on the main body frame 15 with bearing blocks 14, The round rod 13 is used to fix the shaft disc skeleton of the winding ribbon. A sprocket 12 is fixed in the middle of the round rod 13. Two sprockets 12 are fixed on the first round rod at the bottom. One is used as a driven wheel and the sprocket 11 passes through the chain. The other is connected as the driving wheel through the chain to the driven wheel on the second round bar 13 on the top of the first round bar 13. In the same way, two sprockets 12 are installed on the second round bar 13, and the uppermost Only a driven wheel is installed on the 3rd round bar 13. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com