Vertical roll of vertical edger and design method thereof

A design method and technology of edger, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of unqualified products, inconsistent width reduction, slits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

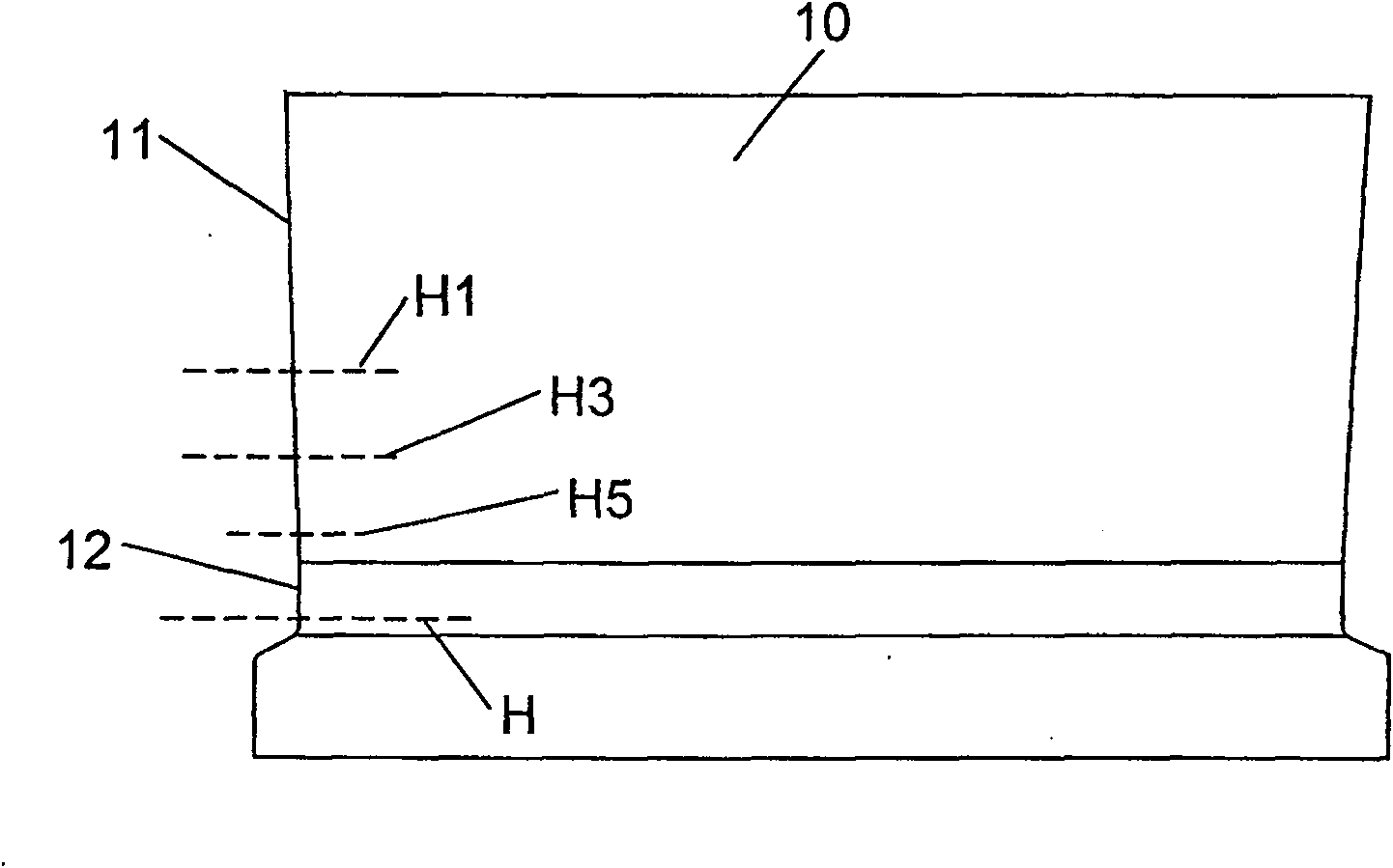

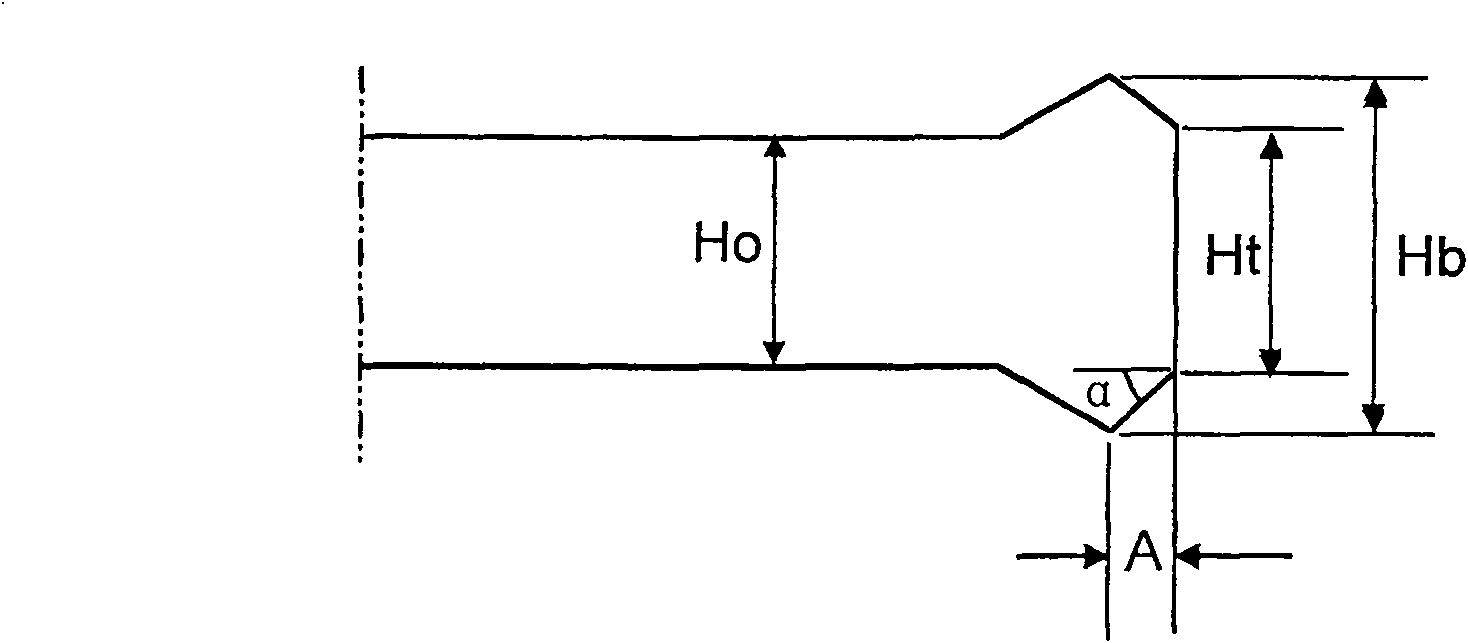

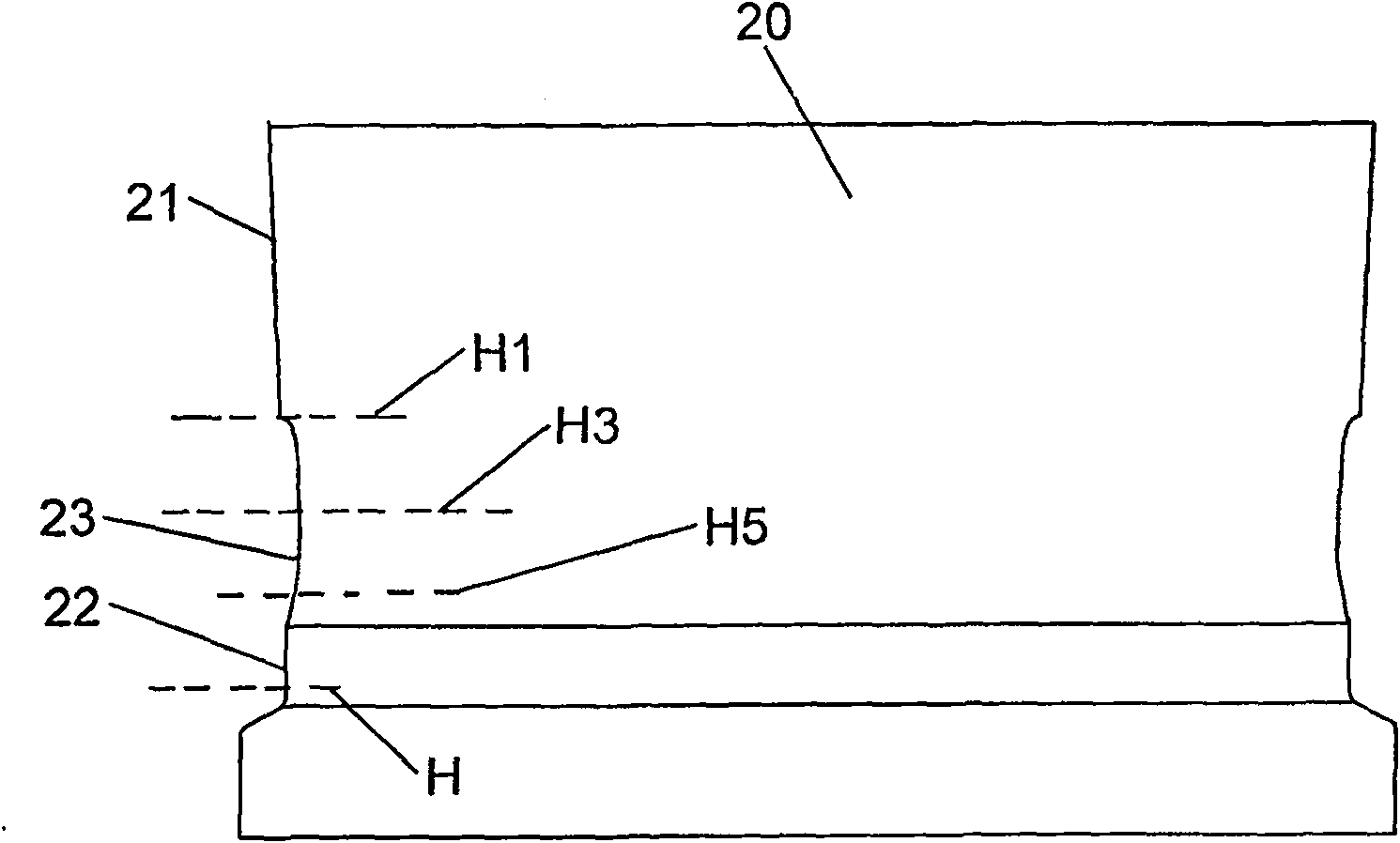

[0022] See image 3 As shown, the two sides of the vertical roll 20 of the vertical roll edging machine of the present invention have a symmetrical structure with the center vertical axis of the vertical roll. Each roll side includes an upper, a middle, and a lower section, and the upper section is a diagonal 21. The lower section is a vertical line 22, and the middle section is an arc line 23 recessed to the inside of the roller. The upper and lower ends of the arc line 23 are respectively connected to the diagonal line 21 and the vertical line 22. The formula of the oblique line 21 in the upper section of the roll side is the same as the oblique line 11 in the prior art (see figure 1 ) Is the same as y=ax, where a=0.05; the middle arc 23 of the roller side is the formula y=ax 2 Parabola 23’ (see Figure 4 ). image 3 Among them, the dashed l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com