Glue solution injector driven by electromagnetic attraction

An electromagnetic suction and ejector technology, which is used in liquid ejection devices, ejection devices, electric solid devices, etc., can solve the problem of difficult to achieve micro-glue and high-viscosity glue spray, spray needle material and size restrictions, and high coaxiality. problems, to achieve the effect of improving service life, small needle stroke, and reducing strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

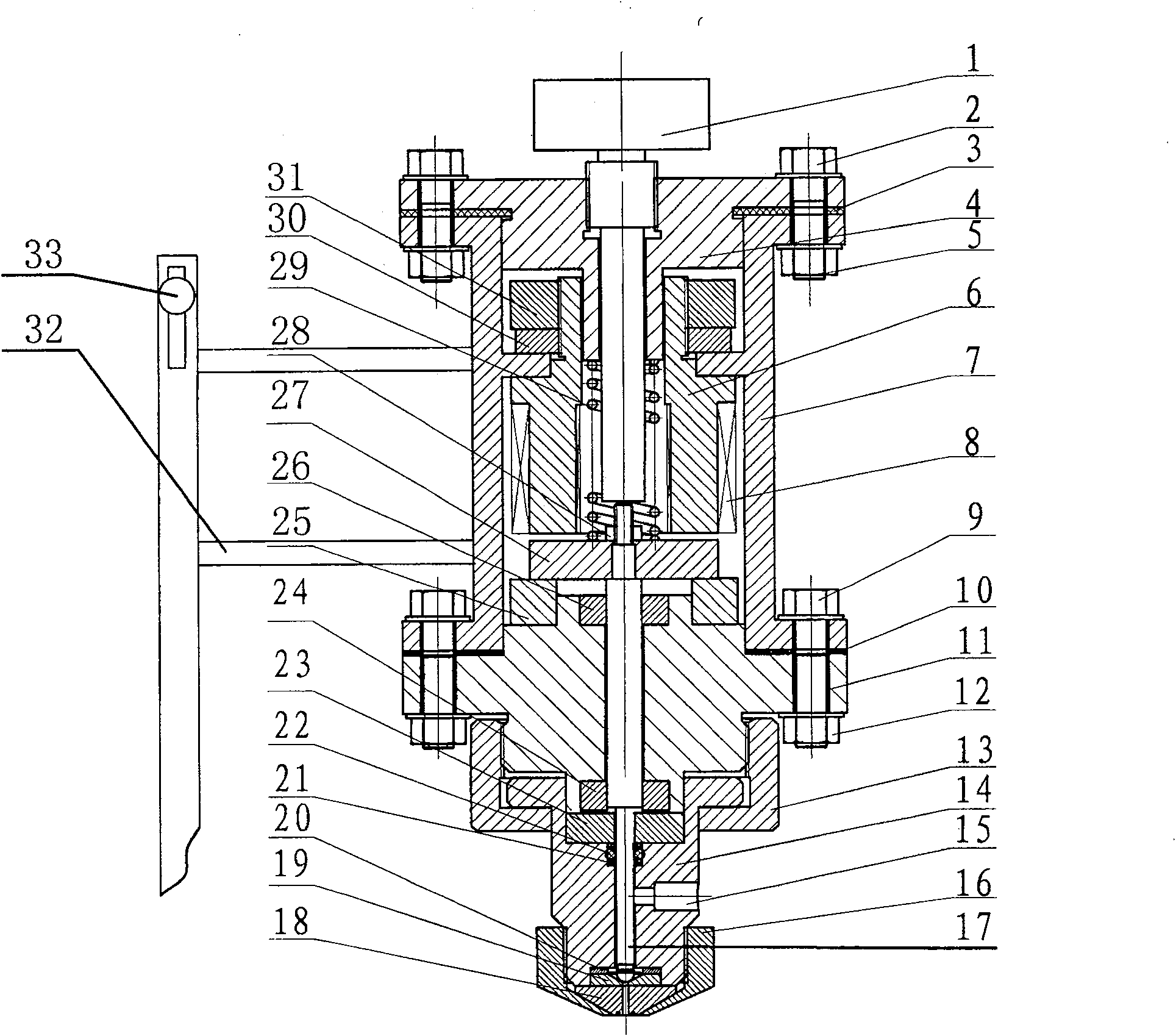

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

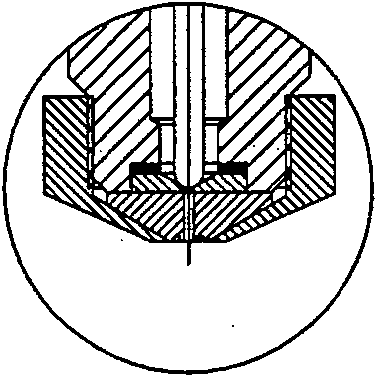

[0022] See attached figure 1 , 2 , the present invention --- including nozzle 17, glue cavity 14, thermal control body 16, needle spring preloading device, electromagnet, stroke adjustment knob 1, is characterized in that: the needle spring preloading device includes spray Needle 17, spring 29, spring preloading device 4, connecting sleeve 11, iron 27; the center of the glue cavity 14 is a hollow glue storage hole, and one side is provided with a rubber inlet pipe 15 communicating with the glue storage hole, One end of the glue storage hole in the glue cavity is screwed with a nozzle 17 through a thermal control body 16, and the other end is connected to the lower end of the needle spring pretensioning device connection sleeve 11 through a nut 13; The connecting sleeve 11 of the tightening device is a hollow sleeve wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com