Cleaning device for optical element

A technology for optical components and cleaning fixtures, applied in cleaning methods and tools, cleaning flexible objects, chemical instruments and methods, etc., can solve problems such as difficult fixation, blocking water flow, loss, etc., to improve cleanliness and yield, Easy to put in and take out, control the effect of easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

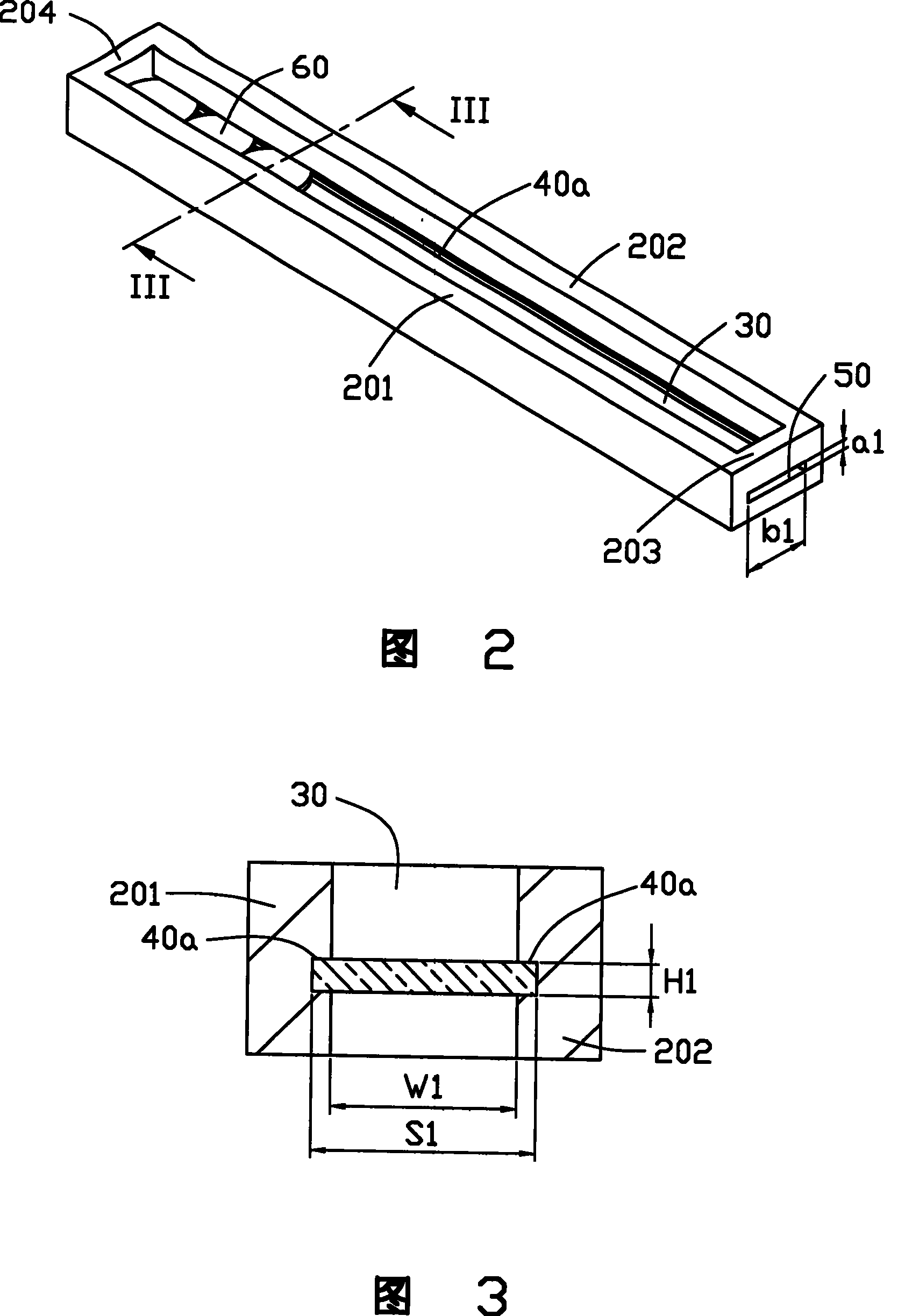

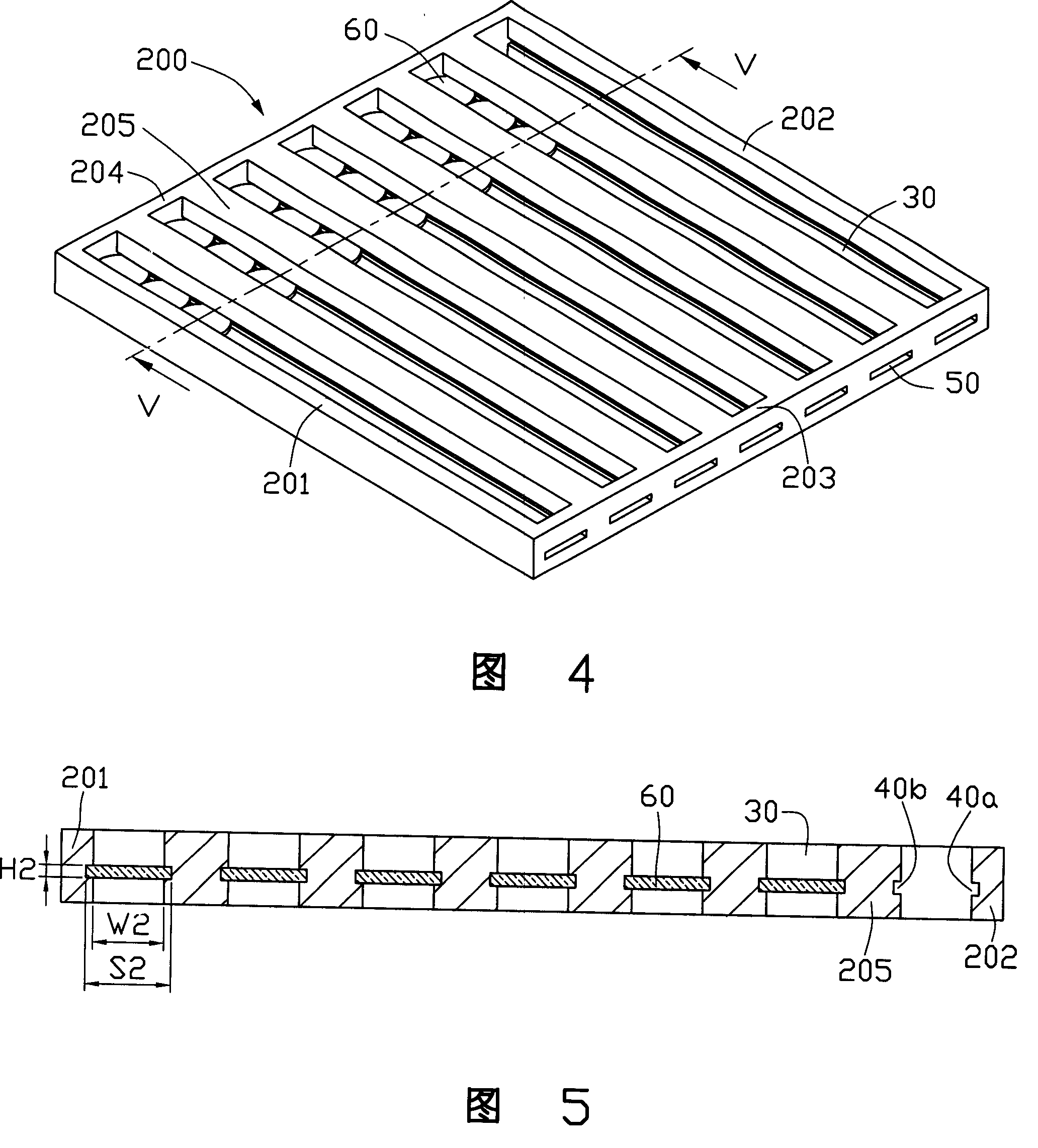

[0026] In the optical element cleaning jig provided in Embodiment 1 and Embodiment 2, the first frame 201, the second frame 202, and the partition 205 are all in the shape of rectangular strips, thereby forming a rectangular strip-shaped cavity 30 for use in It is suitable for cleaning optical components of the same size to be cleaned. Of course, the shape of the accommodating cavity 30 can also be adjusted by changing the shapes of the first frame 201 , the second frame 202 and the partition 205 .

[0027] see Image 6 , is a top view of the optical element cleaning jig 300 provided in the third embodiment. The structure of the optical element cleaning jig 300 is substantially the same as that of the optical element cleaning jig 100 provided in Embodiment 1, which includes a first frame 201 and a second frame 202 opposite to each other, a third frame 203 opposite to a fourth frame 202, and a fourth frame 203 opposite to each other. Border 204 . The difference is that the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com