Punching shaping technology of bar metal

A stamping forming and bar-shaped metal technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems affecting the quality of the forming surface and increasing the production cost of the product, so as to achieve low production cost, prevent wrinkles and simplify the processing technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

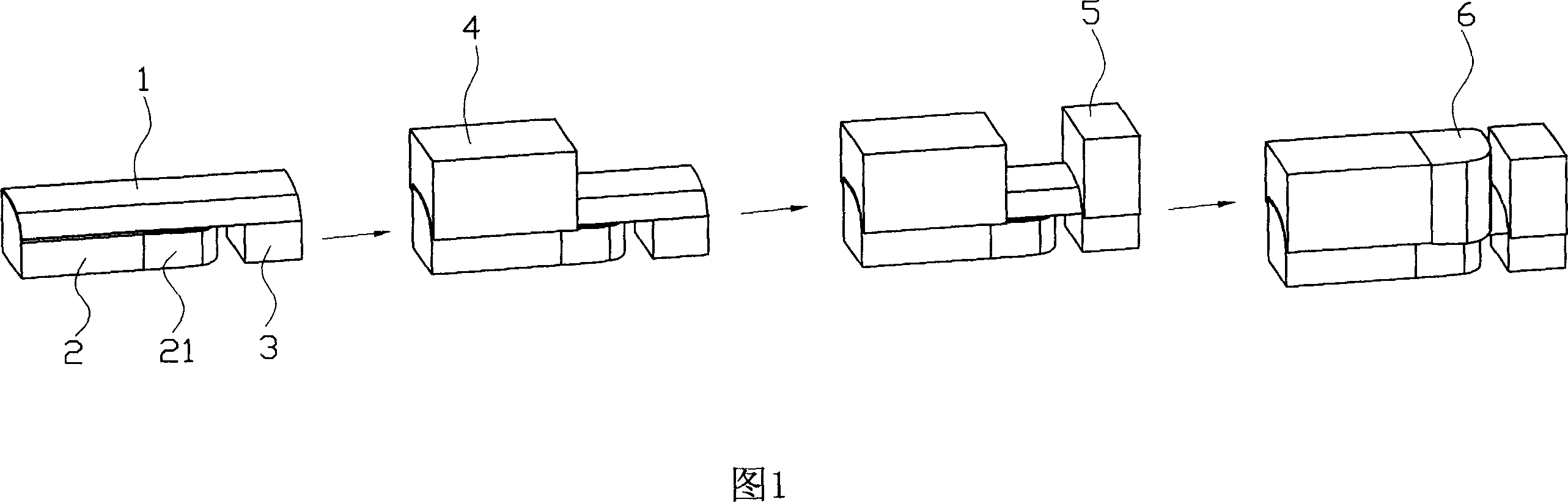

[0017] As shown in Figure 1, the stamping process of the bar-shaped metal adopts the following processing steps: ① place the workpiece 1 to be processed on the front lower module 2 and the rear lower module 3 that are separated from each other, here, the front end of the front lower module Part of the design is in the structure of the punch 21, and the forming area of the workpiece 1 to be processed is directly corresponding to the punch; ②The front upper module 4 corresponding to the front lower module 2 is pressed on the workpiece to be processed on the side of the forming area, that is, pressed against the front The rear end part of the lower module 2, and press the workpiece to be processed on this side, restricting the degree of freedom of the workpiece to be processed on this side, so as to prevent its movement during the forming proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com