System for controlling wind turbine power, consisting in varying the coefficient and size of the swept areas

A technology of wind turbines and control systems, applied in the direction of wind turbines, control of wind turbines, engines, etc., to achieve the effect of less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

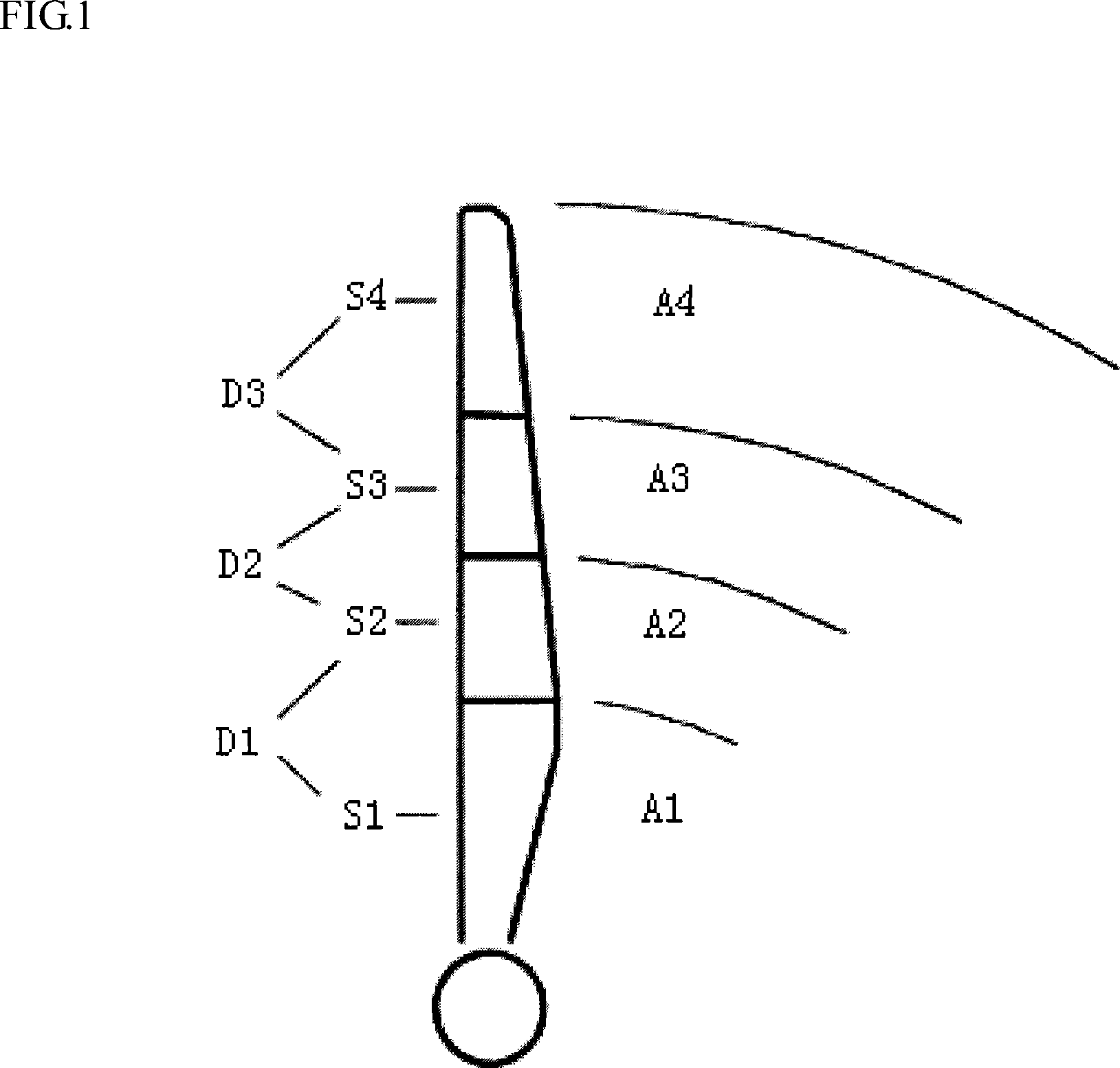

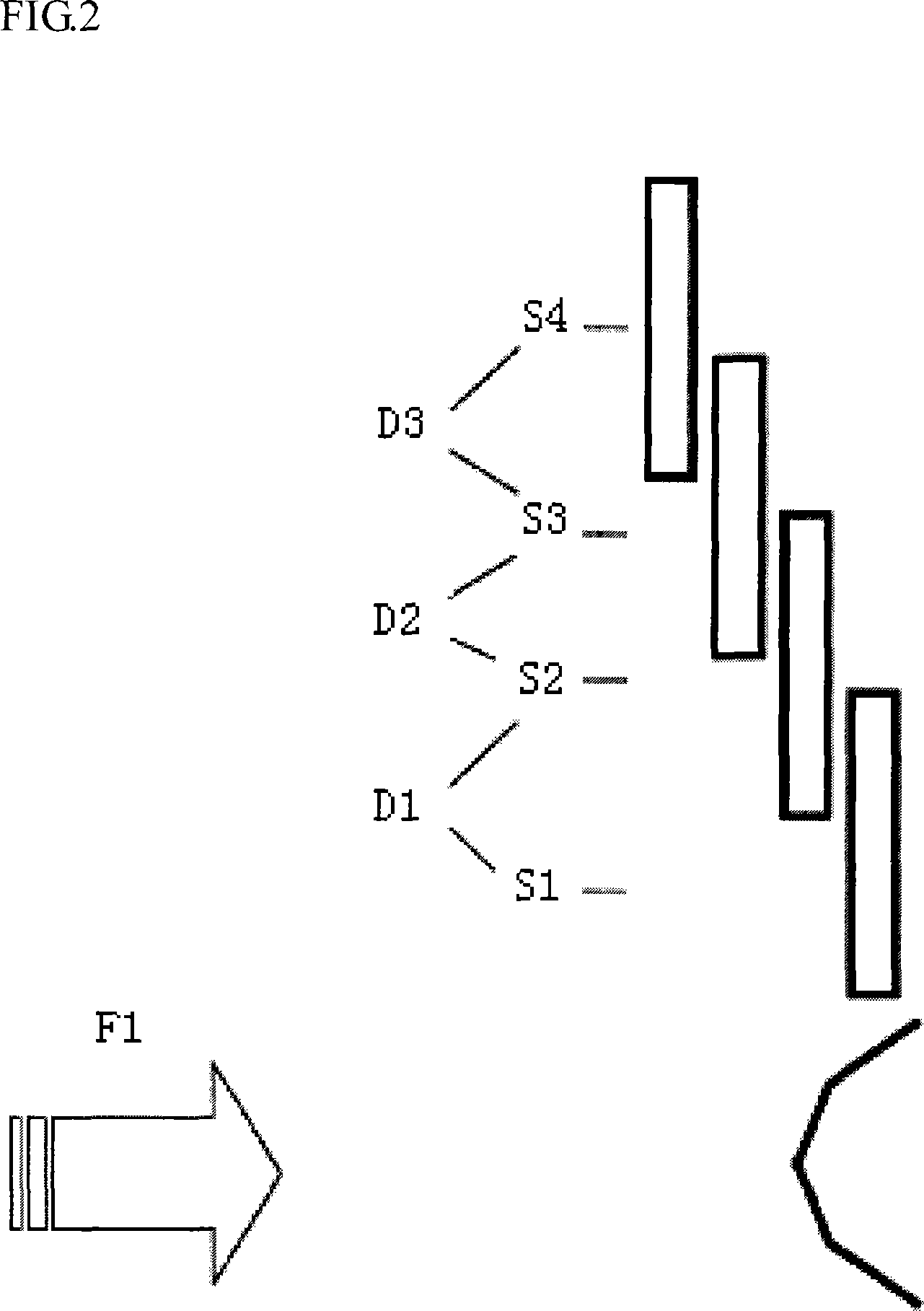

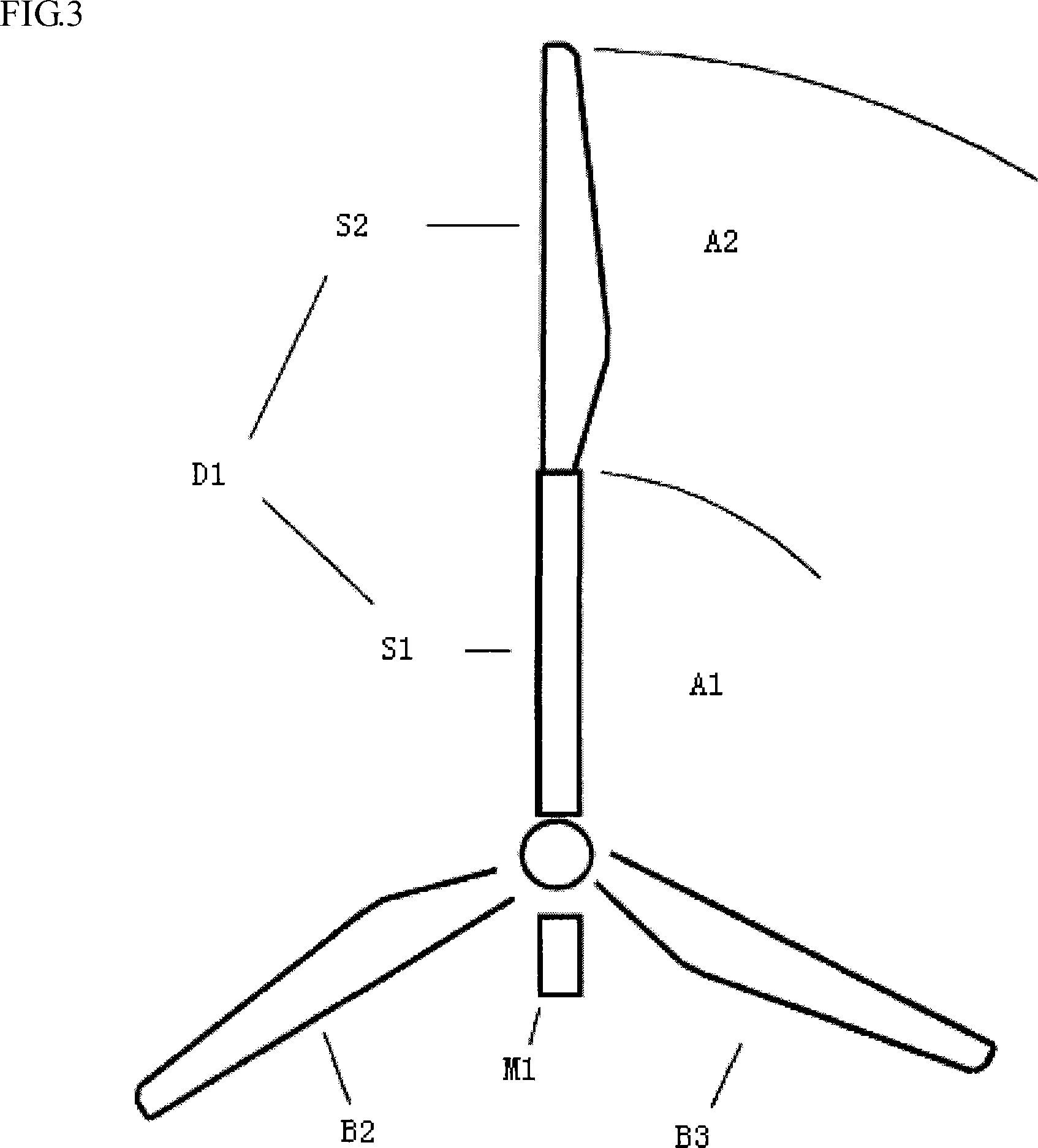

[0025] This system can be applied to wind turbines with one, two or more blades. Figure 3 is a hybrid model of single-bladed and three-bladed wind turbines. Its main blade has two blade segments S1 and S2, and its swept zone areas are A1 and A2, respectively. They form a pair of dynamic blade segments, the cover segment S2 can slide over the S1 segment. S1 is a support structure with a low aerodynamic profile. The movement from the coupling structure of the S2 segment to the S1 segment is generated by the motor drive, or the power transmission is carried out through the cable at other positions. Segment S1 acts as a support structure and guide for movement. Motor rotation is converted to linear motion on the guide. In this way segment S2 can move on the guide. Another option is to use electric linear actuators or hydraulic cylinders. In these cases, the actuator moves along the S1 segment. The moving head of the actuator is attached to the coupling structure of the S2 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com