Dooly compartment self going type elevator

A self-propelled, car technology, applied in the field of elevators, can solve problems such as inconvenience in use, and achieve the effects of simple application, stable operation and high transportation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

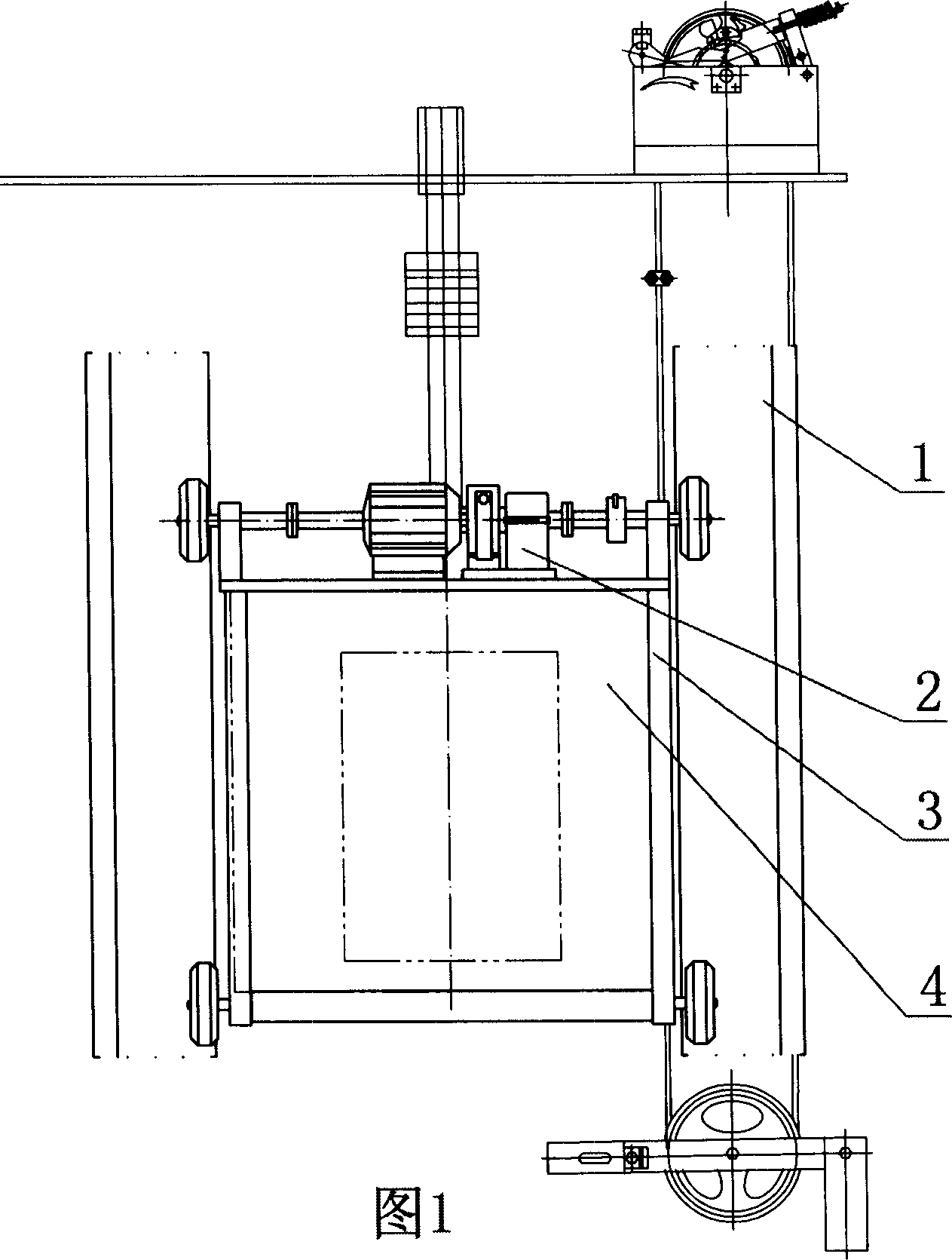

[0010] A kind of specific embodiment shown in Fig. 1, Fig. 2, it comprises elevator shaft and the elevator car that moves up and down in elevator shaft.

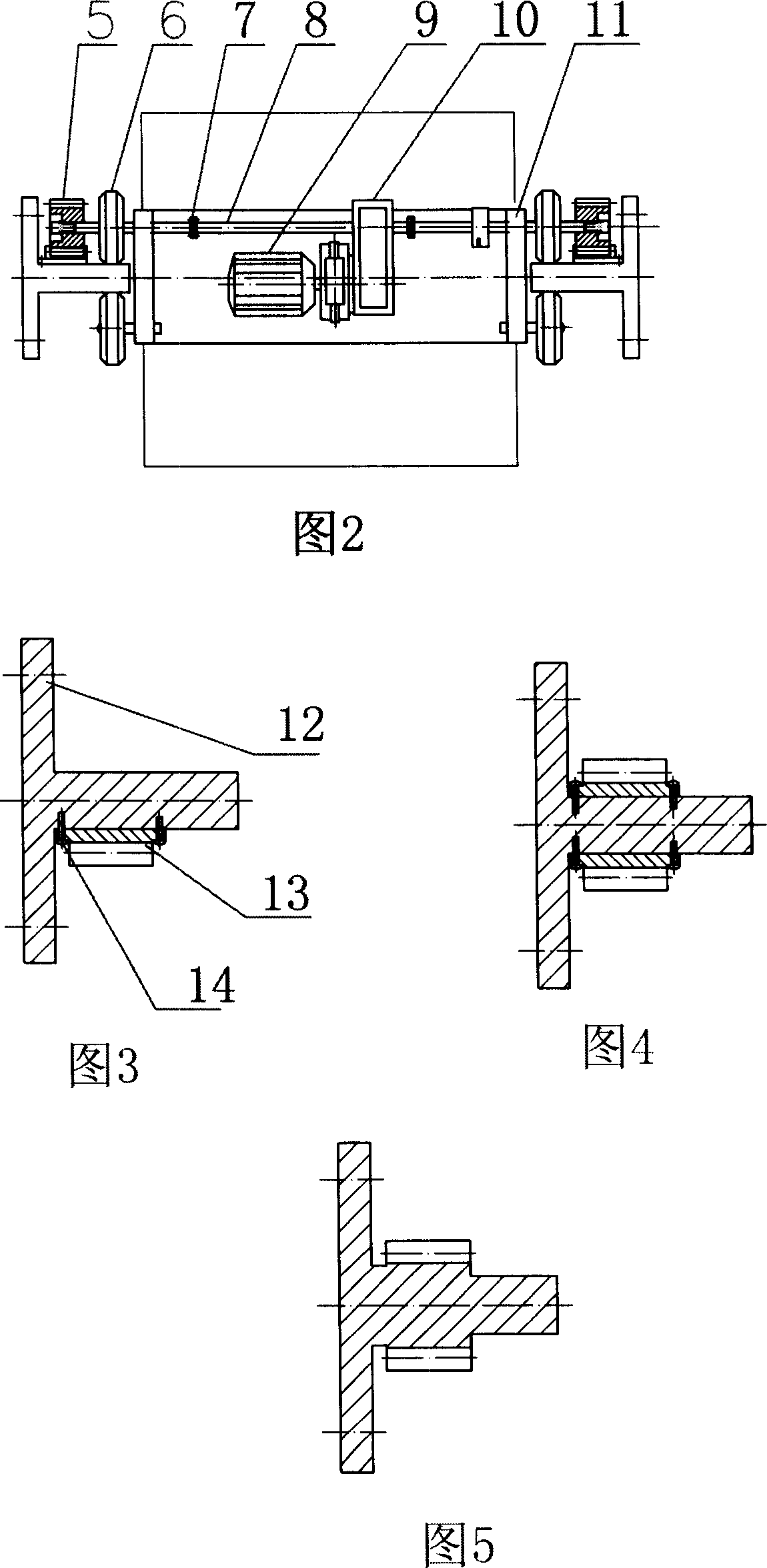

[0011] Two rows of elevator guide rails 1 are fixed in the elevator shaft through guide rail brackets, so that the elevator guide rails 1 and the elevator shaft are integrated. As shown in Figure 2, Figure 3 and Figure 4, the elevator guide rail 1 includes a guide rail body 12 and a rack 13. The cross section of the guide rail body 12 is T-shaped, and the installation orientation of the guide rail body 12 in the elevator shaft is the vertical direction of the T-shaped cross section. side towards the middle of the elevator shaft. As shown in Figure 2, one side of the upper vertical edge of the guide rail body 12 T-shaped section is fixed with the rack 13 by a fastener 14, and as shown in Figure 3, the two sides of the upper vertical edge of the guide rail body 12 T-shaped section pass through Fastener 14 is fixing tooth bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com