Method for producing optically functional film, optically functional film, polarizing plate, optical device and image display

A technology of optical function and manufacturing method, applied in the direction of polarizing elements, chemical instruments and methods, and devices for coating liquid on the surface, etc., can solve the problems of stripe-like spots and dot-like spots with poor appearance, and achieve excellent image display characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

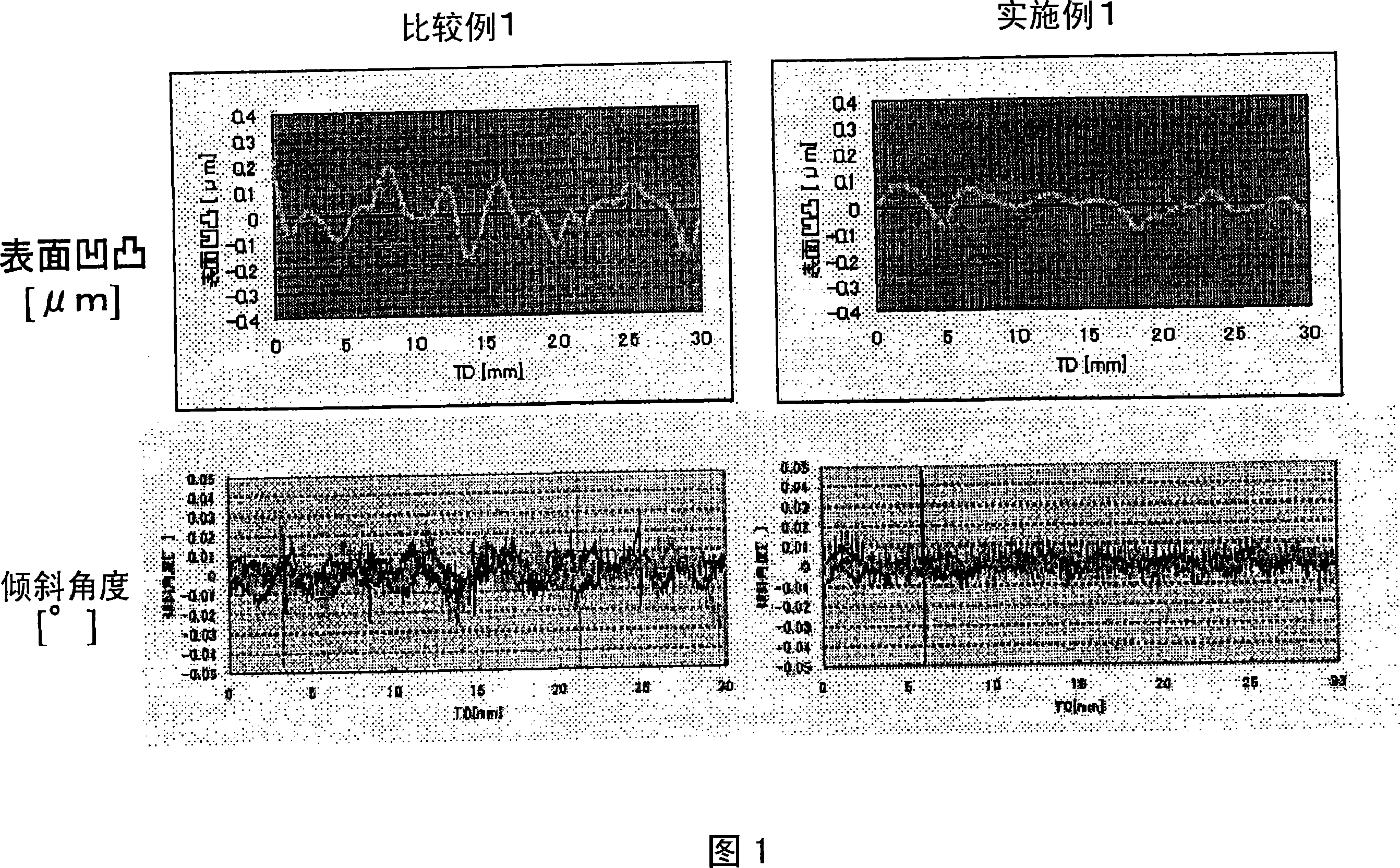

Embodiment 1

[0173] A long film made of cellulose triacetate (manufactured by Fujifilm Co., Ltd., TF-80UL, film thickness 80 μm, width 1330 mm, Tg 145° C.) was used as the base film, and the base film was heated to 145° C. A pair of holding members provided on the device clamps both ends of the width direction of the substrate film respectively, and while moving the pair of holding members along the length direction of the substrate film, the distance between the holding members is gradually expanded to 1.1 times (maximum stretch ratio), the substrate film was stretched. Thereafter, it was relaxed so that the interval between the grasping members became 1.09 times (final draw ratio) (that is, the relaxation rate was 0.992 times).

[0174] On the other hand, polyimide (following formula (32), weight-average molecular weight Mw=140,000) was dissolved in methyl isobutyl ketone to obtain a polyimide concentration of 10% by weight and a viscosity of 200 mPa. sec of polyimide solution.

[0175...

Embodiment 2

[0180] As the base film, an optical functional film was produced in the same manner as in Example 1 except that a long film made of cellulose triacetate (manufactured by Fujifilm Co., Ltd., TFY-80UL, film thickness 80 μm, width 1330 mm) was used.

[0181] Observation of the appearance of the prepared optical functional film with the naked eye shows no streaks. Other measurement results are shown in Table 1.

Embodiment 3

[0183] As the base film, an optical functional film was produced in the same manner as in Example 1 except that a long film made of cellulose triacetate (manufactured by Fujifilm Co., Ltd., TFY-80UL, film thickness 80 μm, width 1475 mm) was used.

[0184] Observation of the appearance of the prepared optical functional film with the naked eye shows no streaks. Other measurement results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com