Temperature gradient method rotary multiple crucible crystal growth system

A technology of crystal growth and temperature gradient method, which is applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of inability to guarantee the doping concentration of doped crystals, low concentration, and decreased diffusion, so as to achieve the advantages of crystal growth and stability The effect of the temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

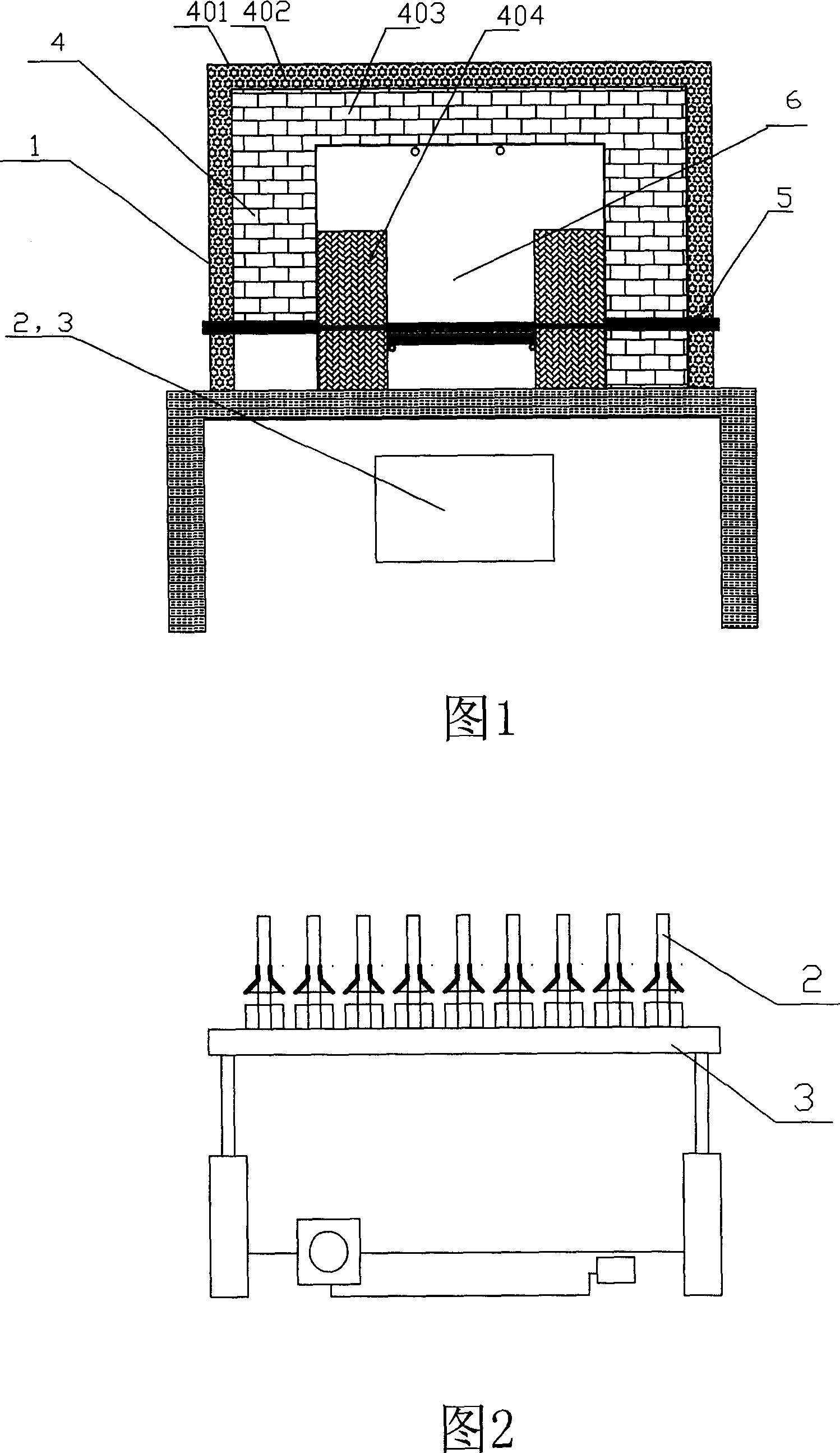

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

[0016] The multi-crucible temperature gradient crystal growth system of the present invention, as shown in Figure 1 and Figure 2, comprises: a crystal furnace 1, a crucible 2 and a lifting device 3 thereof, wherein the crystal furnace comprises a furnace body 4, a heating element 5 and a furnace hearth 6; From the outside to the inside, it includes the shell 401, the insulation cotton layer 402, the insulation brick layer 403 and the refractory layer 404, wherein: the height of the refractory layer 404 is 2 / 3 of the total height of the furnace 6; the heating element is located at 1 / 4 of the height of the furnace 6 . The height of the refractory layer 404 in the furnace can also be 3 / 4 or 5 / 6 of the total height of the furnace; the heating element 5 can also be located at 3 / 8 or 1 / 2 of the height of the furnace 6 . In order to adapt to growing different crystals or doped c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com