Process for preparing lead tungstate-doped crystal

A lead tungstate, crystal technology, applied in the direction of crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of uneven distribution, decreased diffusion, impossible to achieve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a PbF 2 :PbWO 4 Crystal preparation method, comprises the steps:

[0019] (1) PbO and WO with a purity of 99.99% 3 and dopant PbF 2 After the solid powder is dried at about 150 °C, PbO and WO 3 Weighing according to the stoichiometric ratio, the dopant PbF 2 The molar concentration is 0.01%, and the weighed solid powder is pressed into a dense block solid under a pressure of 10Kpa, sintered in an oxidizing atmosphere at 750°C, and kept at a constant temperature of 1130°C for half an hour in a closed platinum crucible filled with oxygen to make it completely melt;

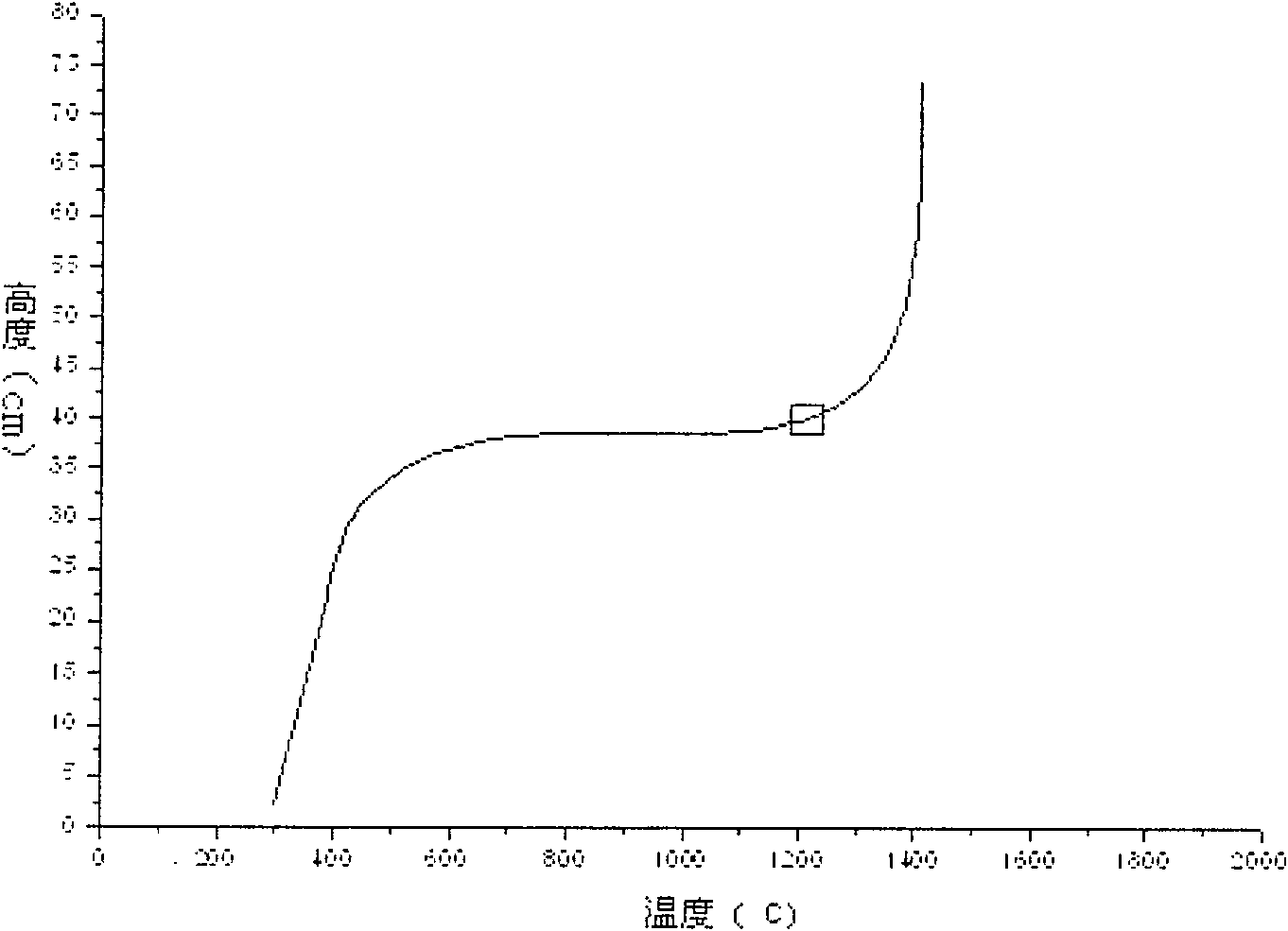

[0020] (2) Introduce the melted raw material into a growth crucible with a seed crystal to form a dense polycrystalline ingot, and place the growth crucible in a temperature-gradient method crystal growth furnace for inoculation and growth to obtain the finished product PbF 2 :PbWO 4 crystal; the temperature distribution curve in the temperature gradient method crystal growth furnace is as follows fi...

Embodiment 2

[0022] a Yb 2 o 3 :PbWO 4 Crystal preparation method, comprises the steps:

[0023] (1) PbO and WO with a purity of 99.99% 3 and dopant Yb 2 o 3 After the solid powder is dried at about 180 °C, PbO and WO 3 Weighing according to the stoichiometric ratio, the dopant Yb 2 o 3 The molar concentration is 0.05%, and the weighed solid powder is pressed into a dense block solid under a pressure of 30Kpa, sintered in an oxidizing atmosphere at 900°C, and kept at 1160°C for half an hour in a closed platinum crucible filled with oxygen to make it completely melt;

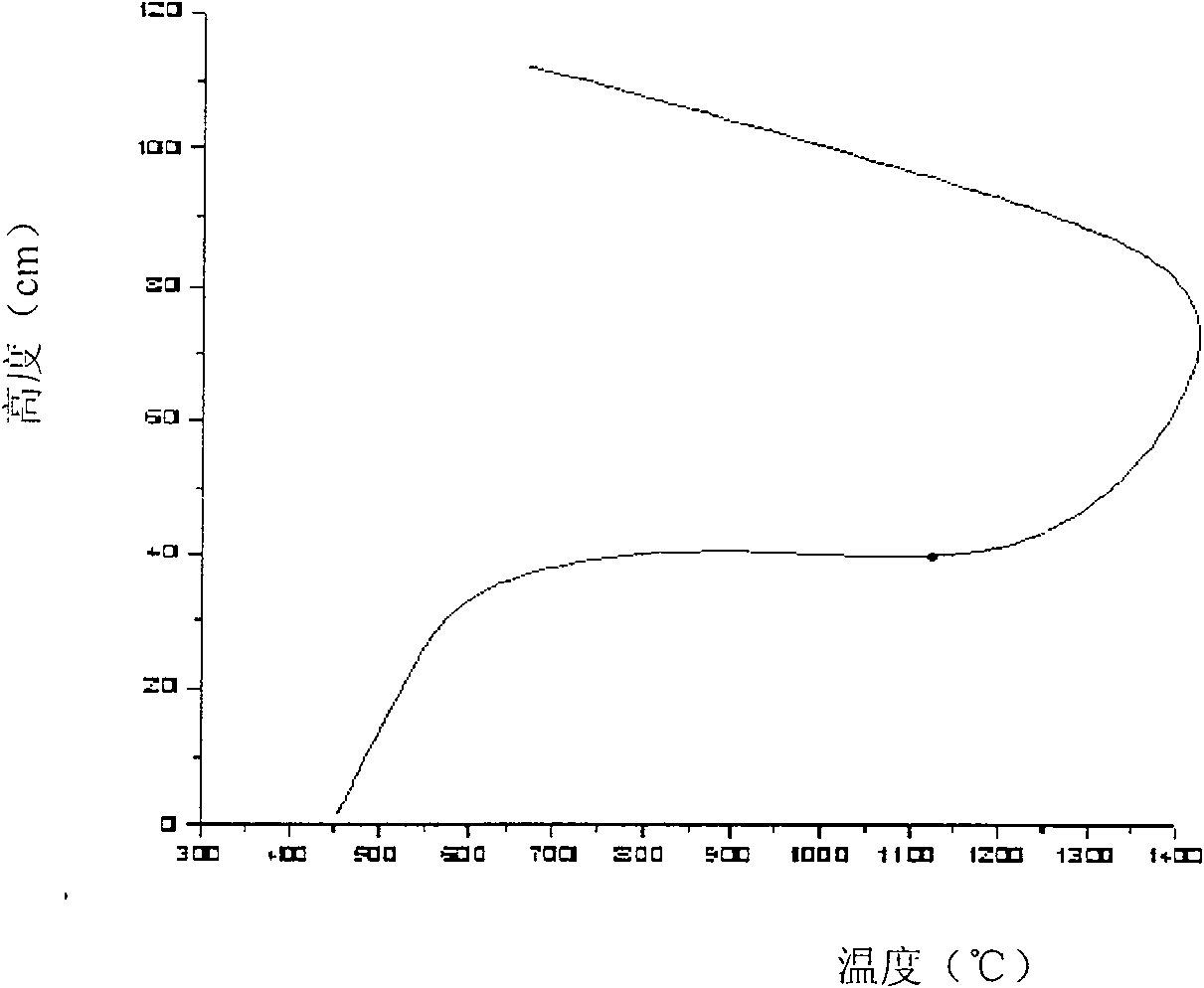

[0024] (2) Introduce the melted raw material into a growth crucible with a seed crystal to form a dense polycrystalline ingot, and place the growth crucible in a temperature-gradient method crystal growth furnace for inoculation and growth to obtain the finished product Yb 2 o 3 :PbWO 4 crystal; the temperature distribution curve in the temperature gradient method crystal growth furnace is as follows figure 2 It ...

Embodiment 3

[0026] a BaF 2 :PbWO 4 Crystal preparation method, comprises the steps:

[0027] (1) PbO and WO with a purity of 99.99% 3 and dopant BaF 2 After the solid powder is dried at about 200 °C, PbO and WO 3 Weighing according to the stoichiometric ratio, the dopant BaF 2 The molar concentration is 0.1%, and the weighed solid powder is pressed into a dense block solid under a pressure of 50Kpa, sintered in an oxidizing atmosphere at 1000°C, and kept at a constant temperature of 1200°C for half an hour in a closed platinum crucible filled with oxygen to make it completely melt.

[0028] (2) Introduce the melted raw material into a growth crucible with a seed crystal to form a dense polycrystalline ingot, and place the growth crucible in a temperature-gradient method crystal growth furnace for inoculation and growth to obtain the finished product BaF 2 :PbWO 4 crystal; the temperature distribution curve in the temperature gradient method crystal growth furnace is as follows fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com