Device on the spinning preparation machine for monitoring and/or adjusting clearance of parts

A technology for equipment and components, applied in the field of equipment located on spinning preparation machines for monitoring and/or adjusting gaps on components, can solve the problems of protruding tooth tips or small conductive particles grinding off, false shutdowns, etc., to avoid Heavy contact, avoid machine downtime, prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

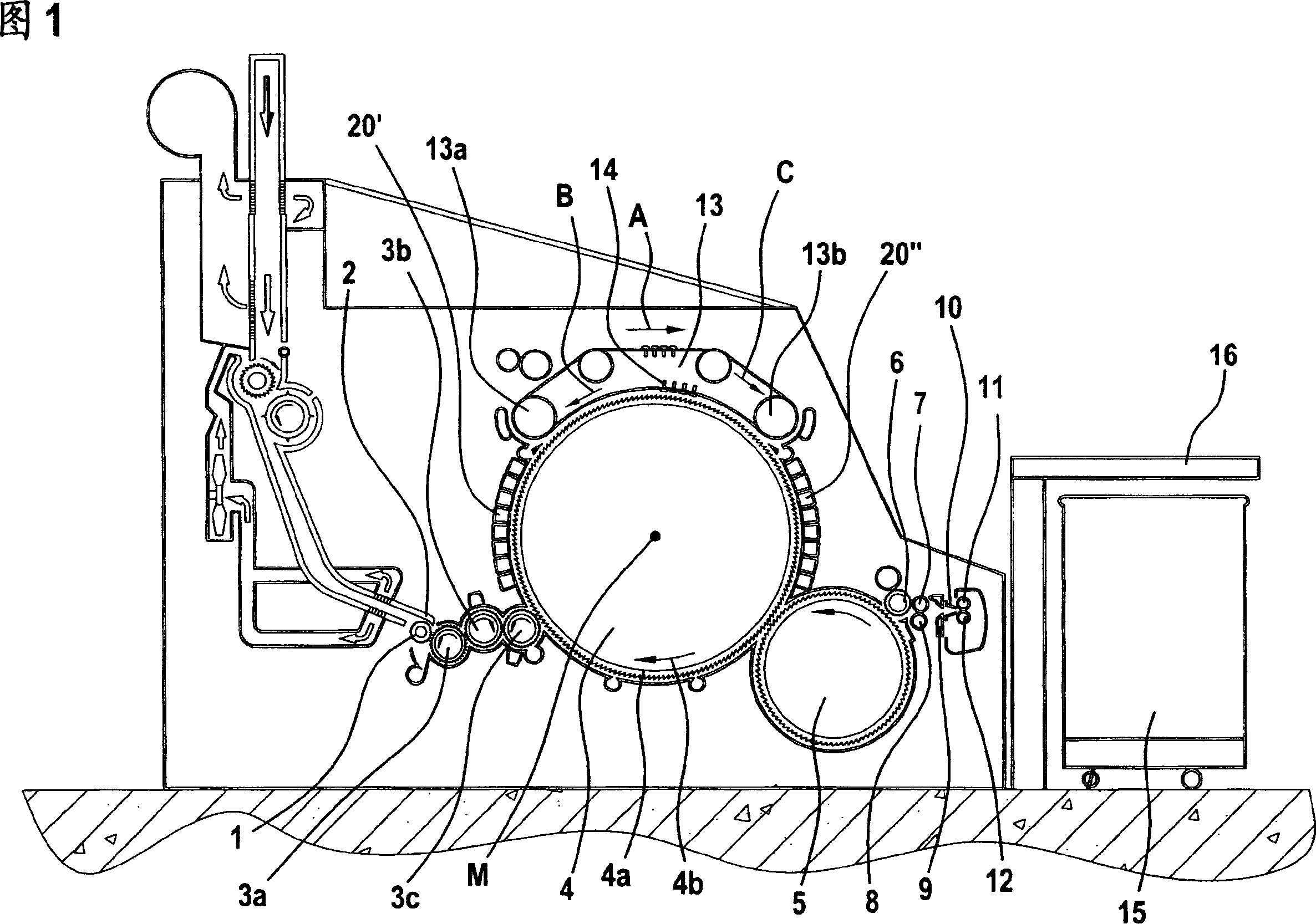

[0026] Figure 1 shows a flat card, for example a Trutzschler flat card TC 03, with a feed roller 1, a feed pan 2, licker-in rollers (licker-in) 3a, 3b, 3c, cylinder 4, small cylinder 5, stripper Take-off rollers 6, extrusion rollers 7, 8, web deflection device 9, web funnel 10, delivery rollers 11, 12, revolving cover with flat guide rollers 13a, 13b and flat bars 14 Plate 13 , bucket 15 and can coiler 16 . The direction of rotation of the rollers is indicated by the respective curved arrows. The letter M designates the midpoint (axis) of the drum 4 . Reference numeral 4a denotes a felt cloth, and 4b denotes the direction of rotation of the drum 4 . Arrow A indicates the working direction. Curved arrows drawn on the rollers indicate the direction of rotation of the rollers.

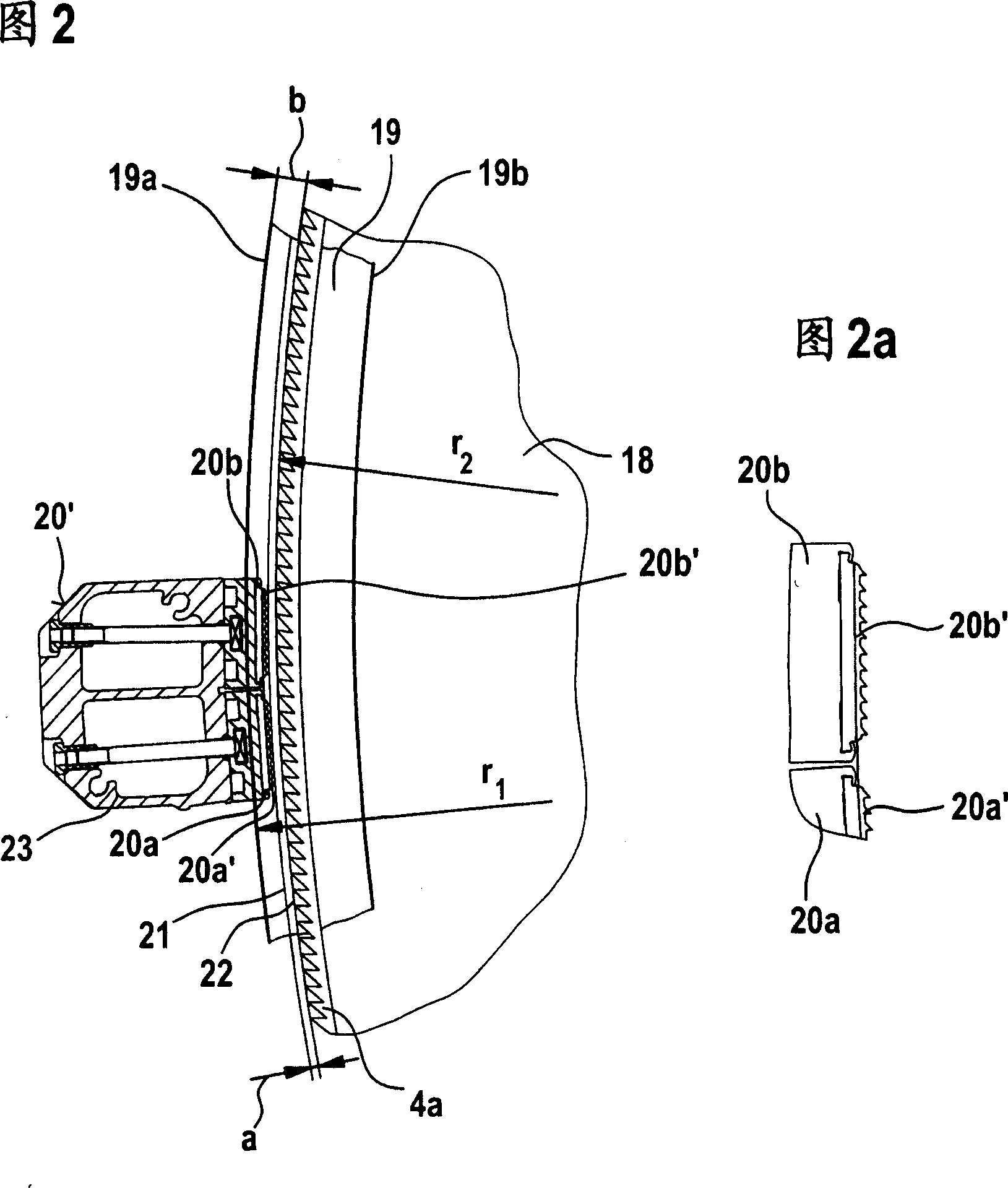

[0027] Referring to Fig. 2, on each side of the carding machine transversely to the frame (not shown) is fixed with a roughly semicircular rigid side plate 18; on the outside in its circumferential ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap