Cast-in-situ concrete hollow board

A technology of hollow slab and cast-in-place concrete, which is applied in the direction of floor slabs, building components, buildings, etc., and can solve problems affecting the compactness of the concrete structure in the floor, affecting the construction quality of the floor, and not being able to arrange hollow carcass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

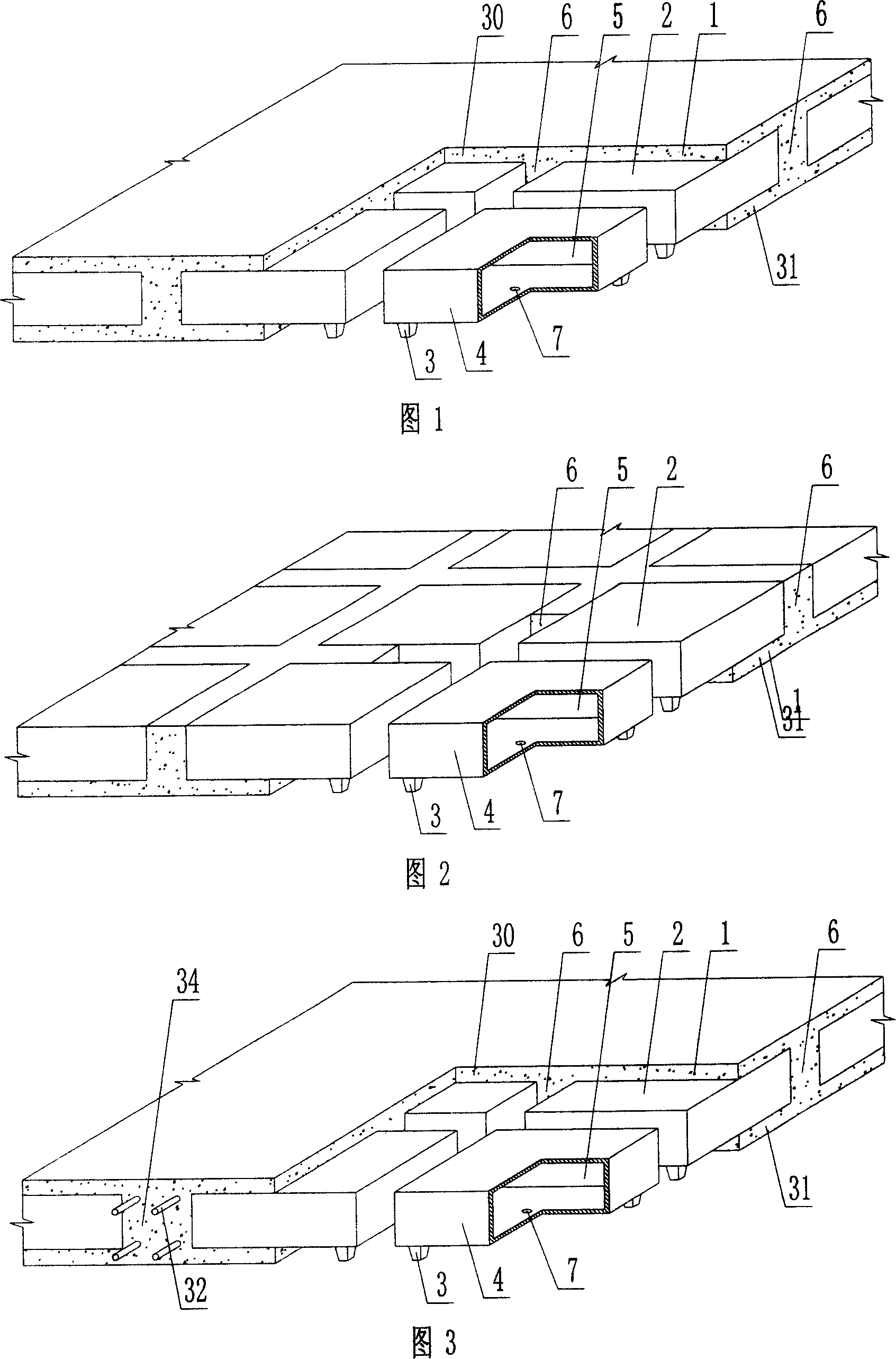

[0082] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

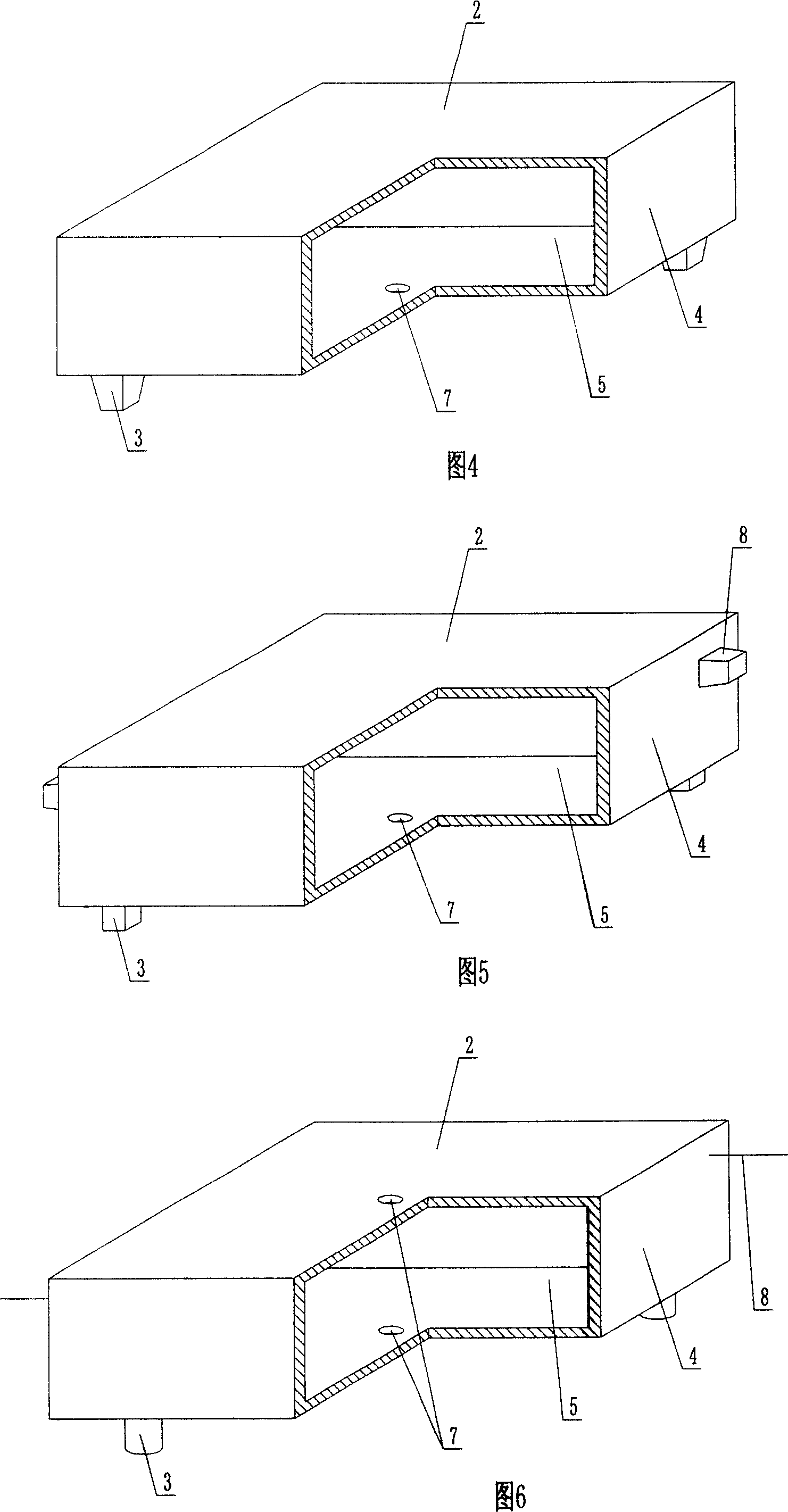

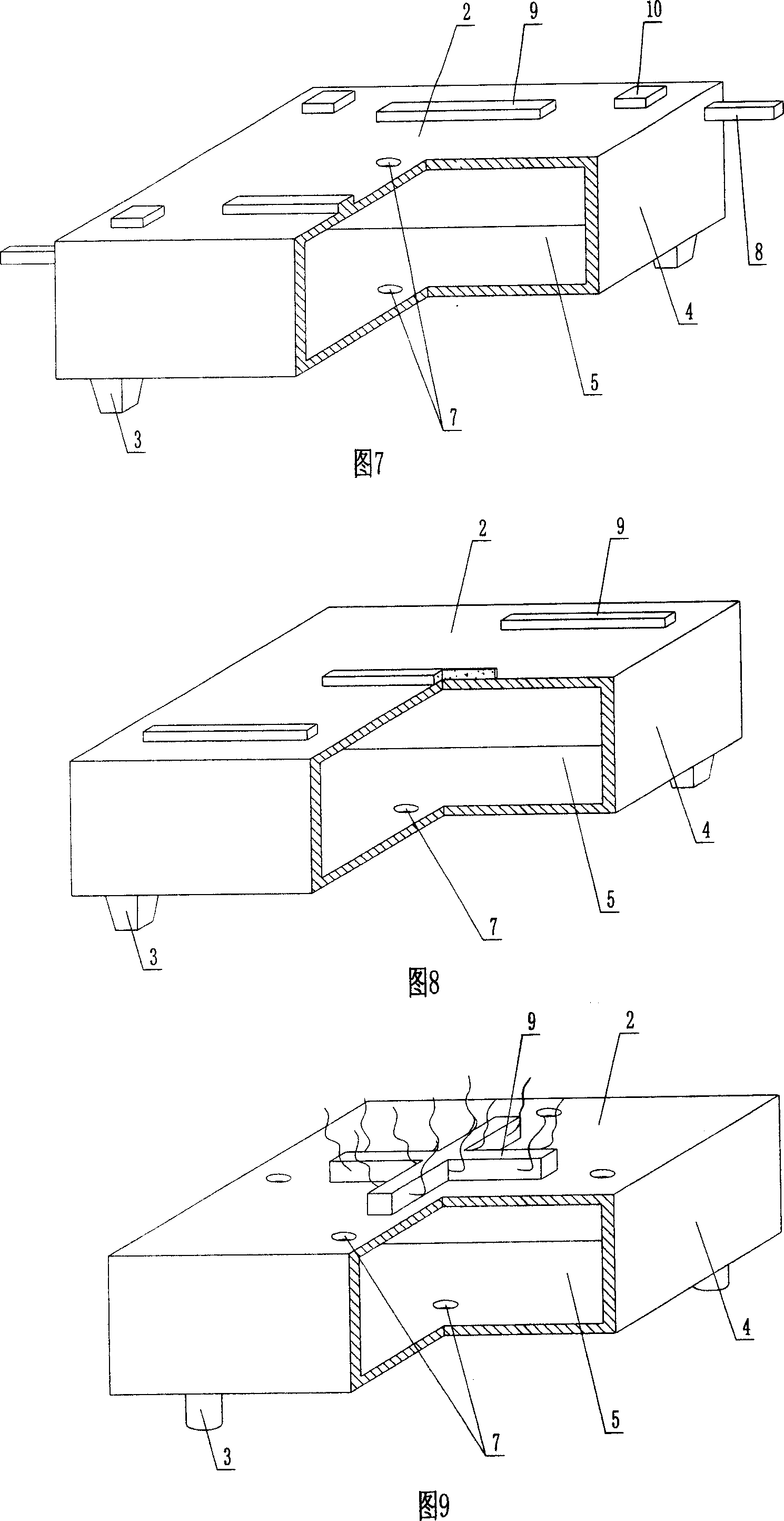

[0083] A cast-in-place concrete hollow slab, comprising a reinforced concrete 1 and a hollow carcass 2, the hollow carcass 2 is wrapped in the reinforced concrete 1, the bottom outer wall 4 of the hollow carcass 2 is provided with a support foot 3, and the outer wall 4 is enclosed to form A hollow carcass 2 with a cavity 5, the hollow carcass 2 is a cast-in-place reinforced concrete rib 6 formed by reinforced concrete 1, and the hollow carcass 2 is characterized in that the bottom outer wall 4 of the hollow carcass 2 has at least one Deflated small holes7. In each drawing, 1 is reinforced concrete, 2 is hollow carcass, 3 is support foot, 4 is outer wall, 5 is cavity, 6 is cast-in-place reinforced concrete rib, 7 is vent hole, in the following drawings, Those with the same number have the same description. As shown in Fig. 1, Fig. 2 and Fig. 3, the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com