Plane display and display driving method

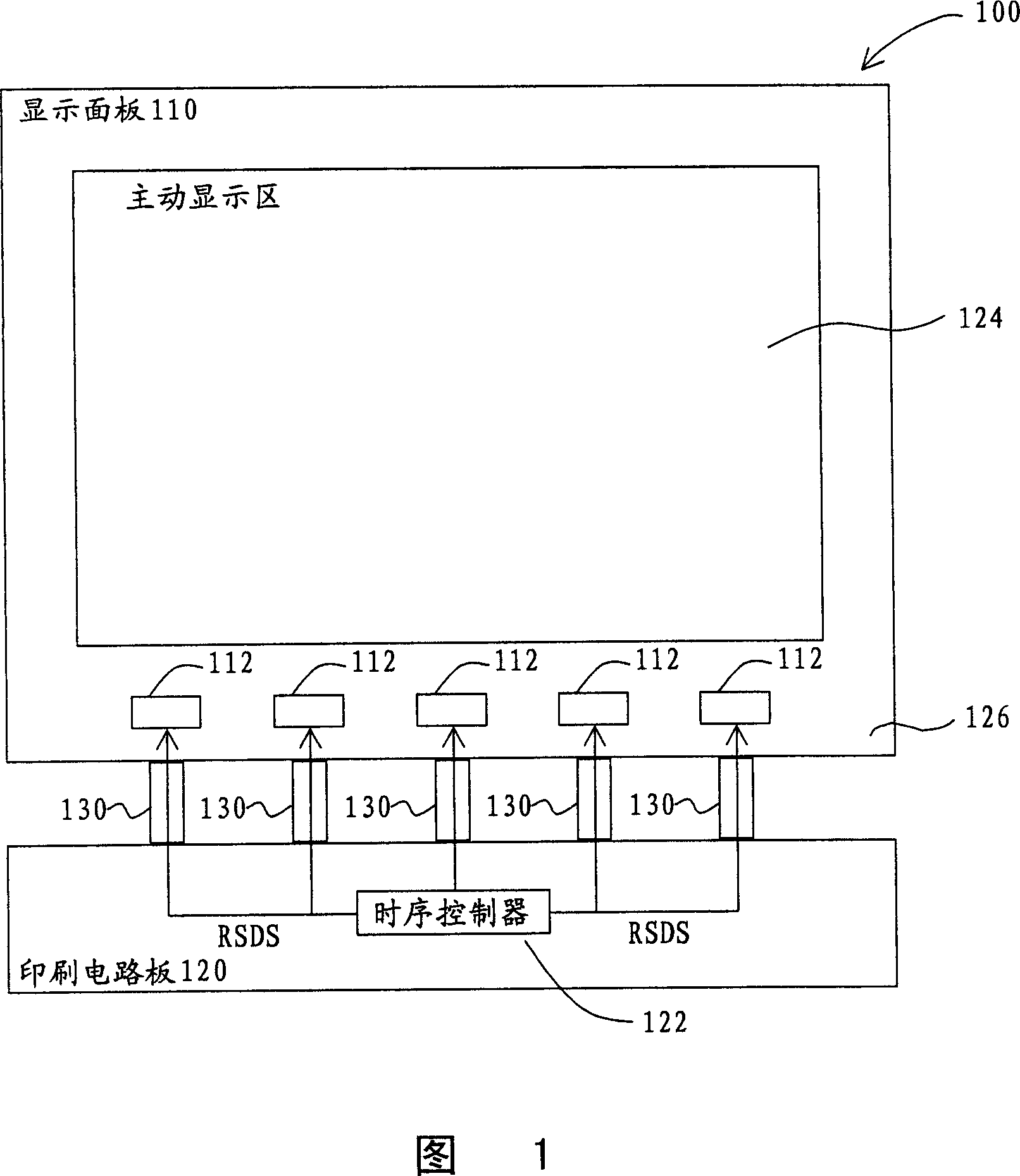

A display driving and display technology, which is applied to static indicators, cathode ray tube indicators, instruments, etc., can solve the problems of affecting the yield of flat-panel displays, high impedance of signal lines, increasing the weight of flat-panel displays 100, and manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

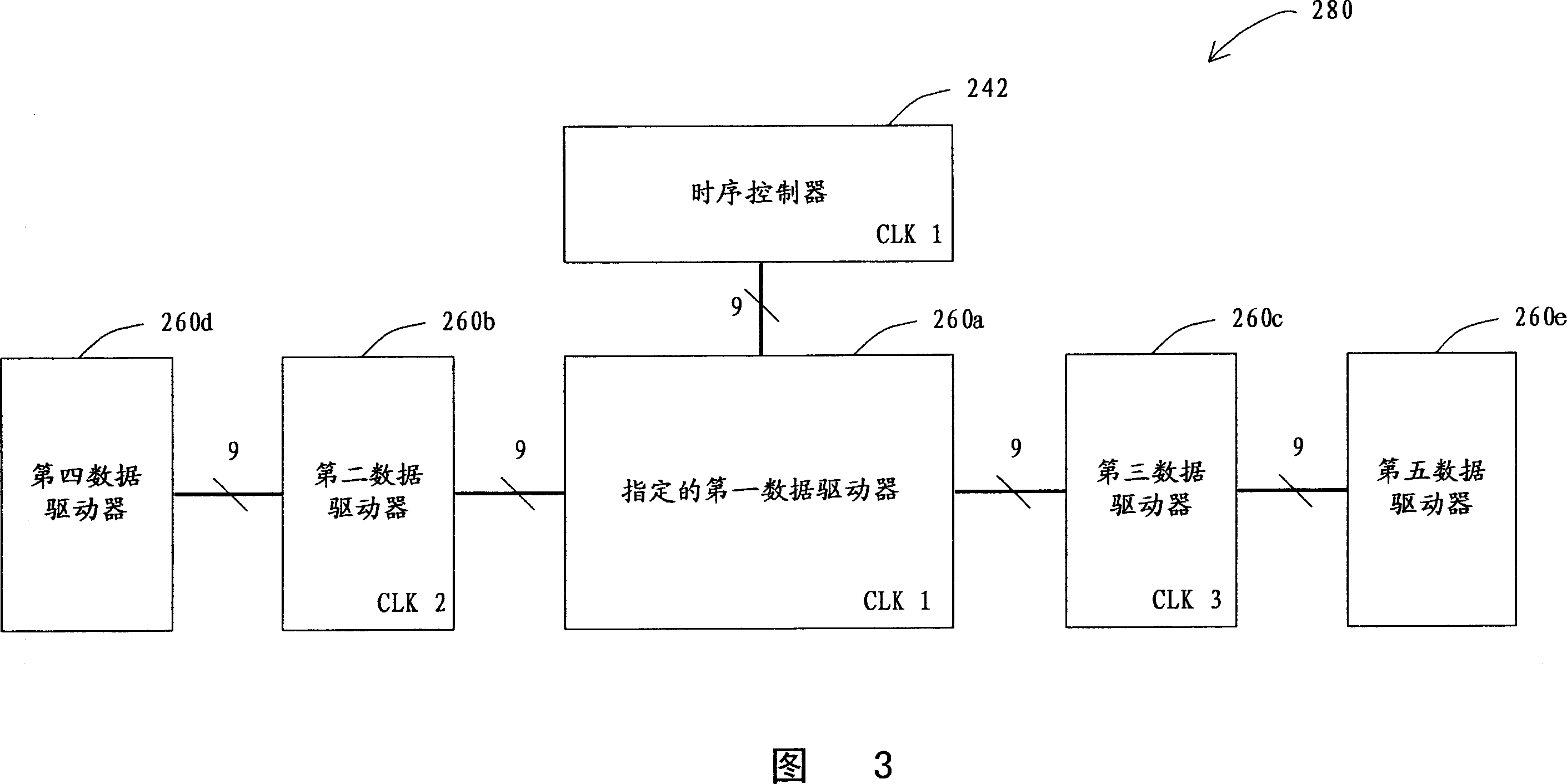

[0073] The flat panel display in the following embodiments, such as a liquid crystal display, is used for the timing controller to transmit the pixel data to the specified data driver, and then the specified data driver transmits the pixel data to other data drivers.

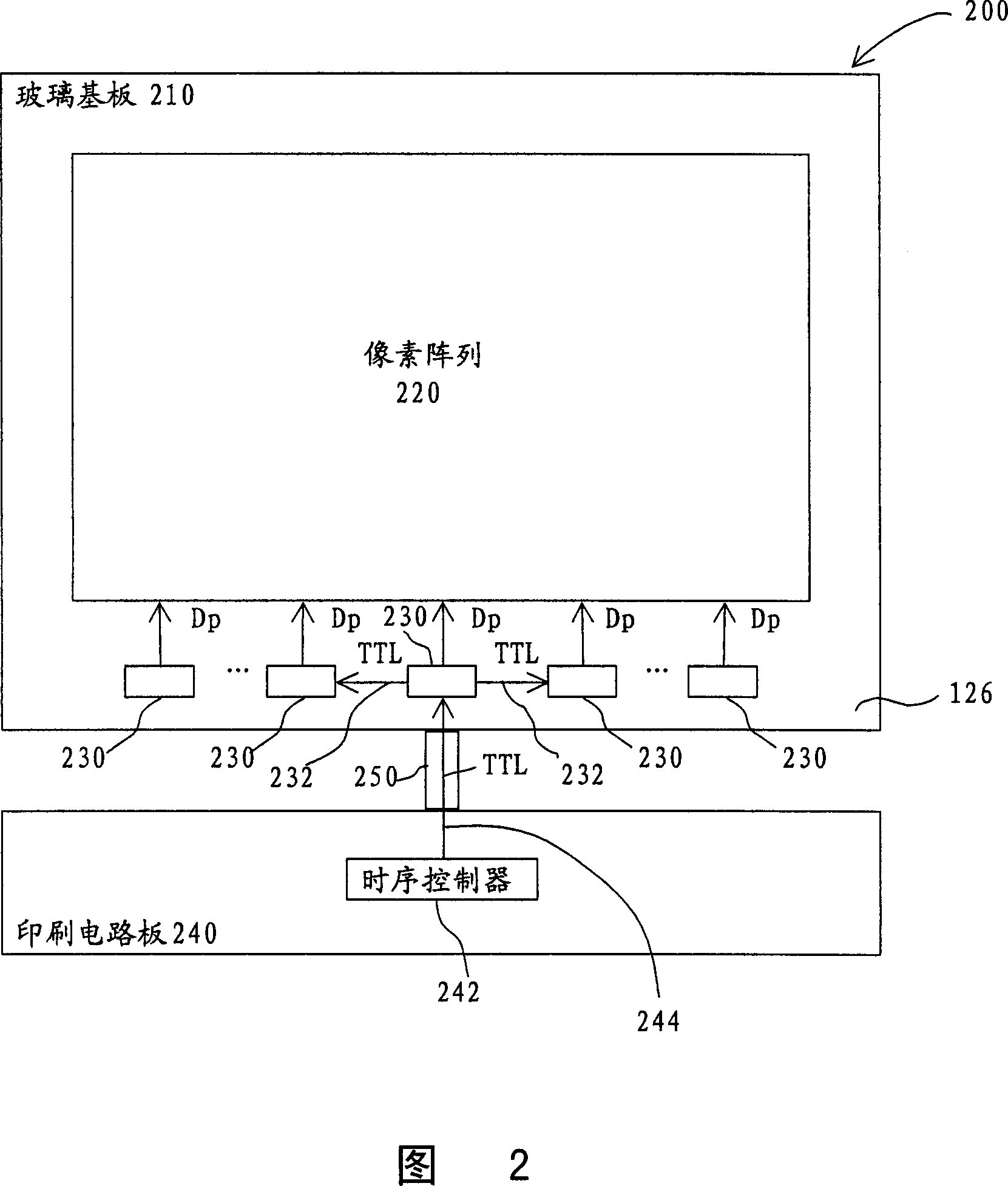

[0074] Please refer to FIG. 2 , which shows a structural block diagram of a flat panel display according to a preferred embodiment of the present invention. The flat panel display 200 , such as a liquid crystal display, includes a glass substrate 210 , a pixel matrix 220 , a data driver 230 and a printed circuit board 240 . The pixel array 220 includes arrayed pixel circuits disposed on the glass substrate 210 for displaying images. The data driver 230 is disposed on the glass substrate 210 using gold contact bump technology (described later). The transmission lines 232 between the data drivers are directly disposed on the glass substrate 210 in a WOA transmission structure. The data driver 230 outputs the pix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com