Escalator energy-saving control process and apparatus

An escalator and energy-saving control technology, which is applied in the field of elevator control devices, can solve the problems of large starting current and energy consumption, and achieve the effects of prolonging service life, reducing wear and improving power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

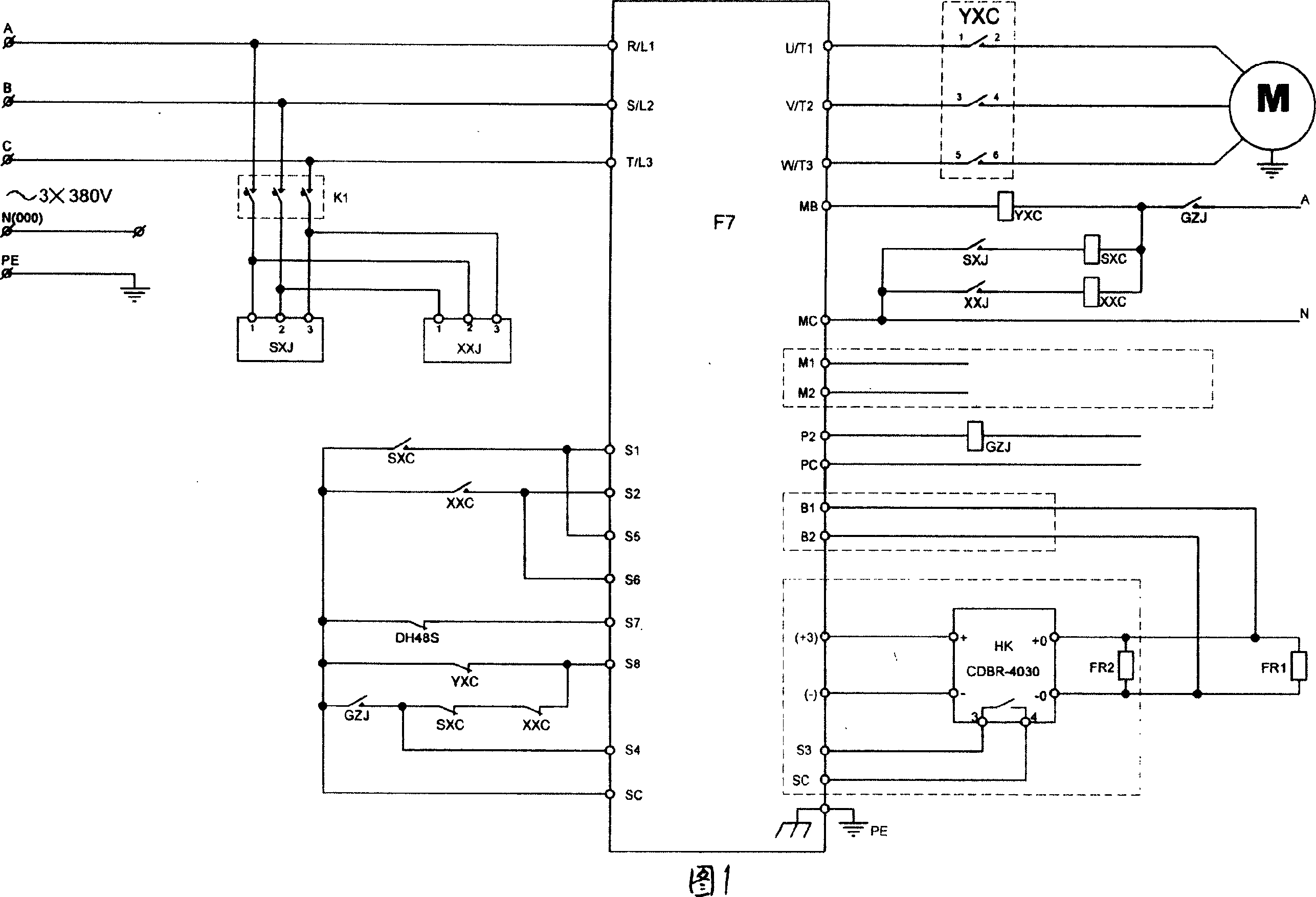

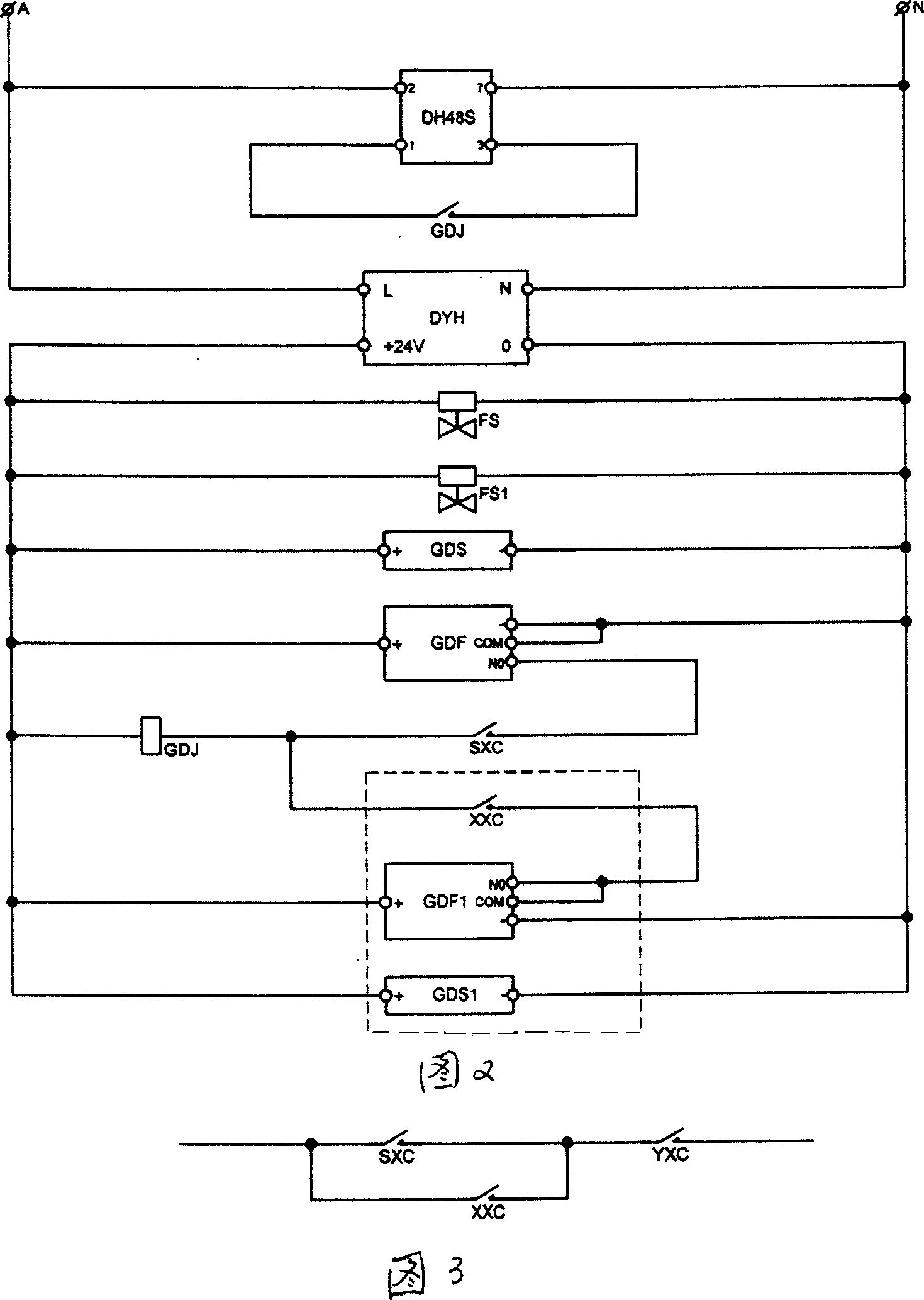

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0015] The work of the present invention is completed through several links such as uplink and downlink signal acquisition, speed signal acquisition, brake control, speed regulation and energy-saving operation, brake monitoring (selection), ladder speed monitoring (selection), and several links; the specific working principle is as follows:

[0016] Up and down running (Fig. 1): The operator starts the escalator according to the regulations, and the original control device of the escalator automatically detects that each safety switch is qualified and then provides three-phase alternating current A, B, C to the wiring terminals of the escalator motor in the circuit of the present invention, Connect with the incoming line terminals R / L1, S / L2, T / L3 of the inverter as the inverter power supply. On the other hand, it is connected to the upstream relay SXJ, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com