Steel concrete combined bridge front panel

A technology for concrete and composite bridges, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of self-heavy, large steel consumption and high construction cost of superimposed bridge decks, so as to improve overall stiffness, reduce steel consumption, and reduce construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

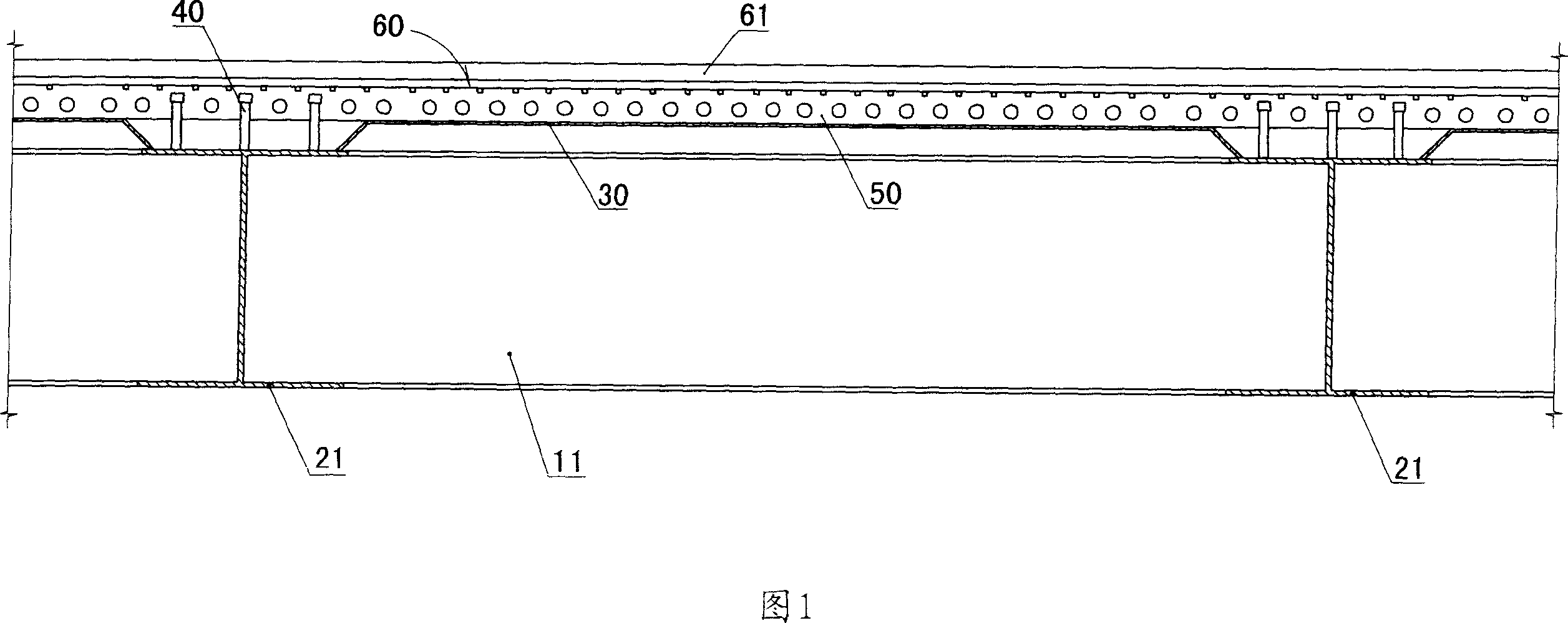

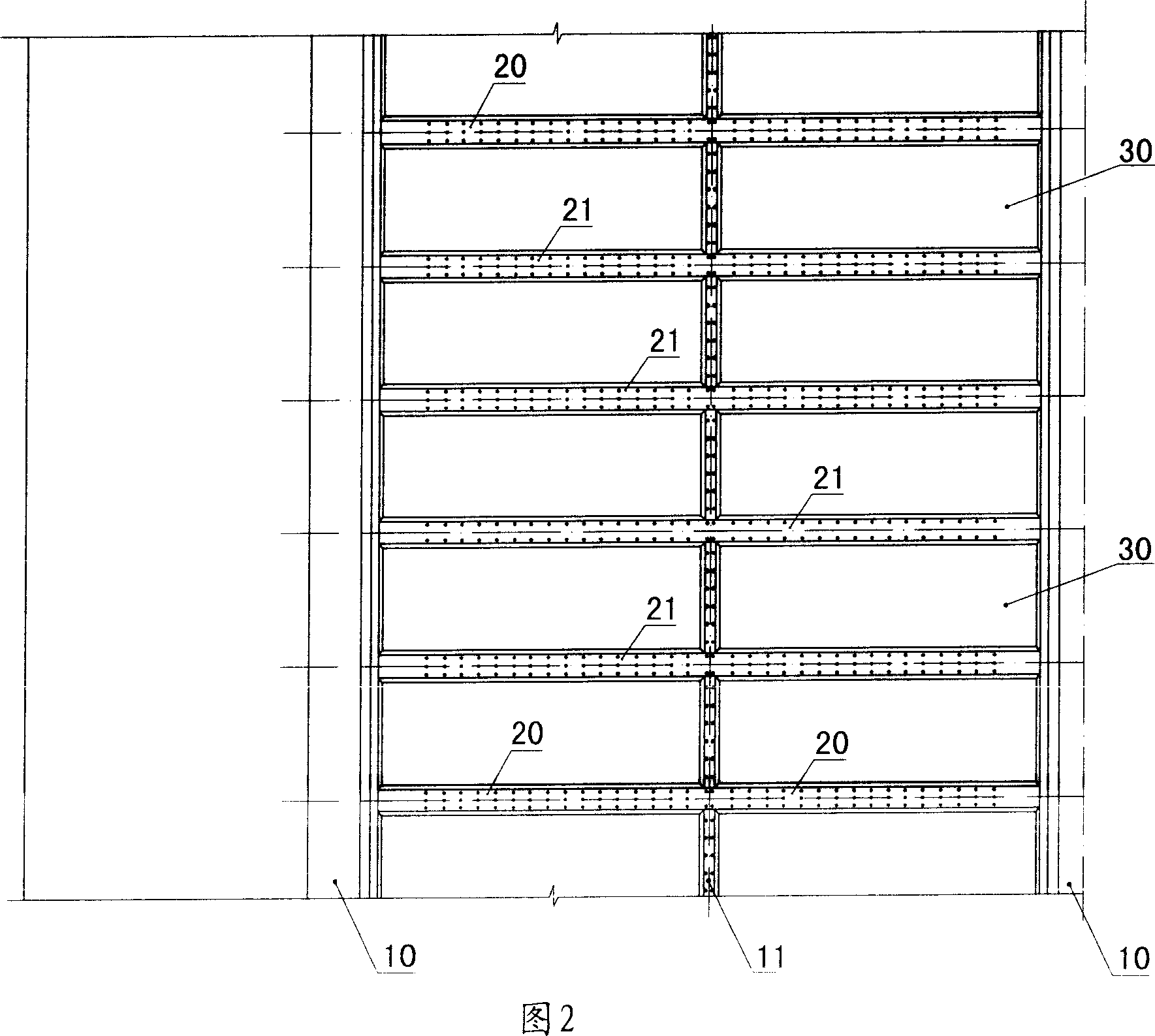

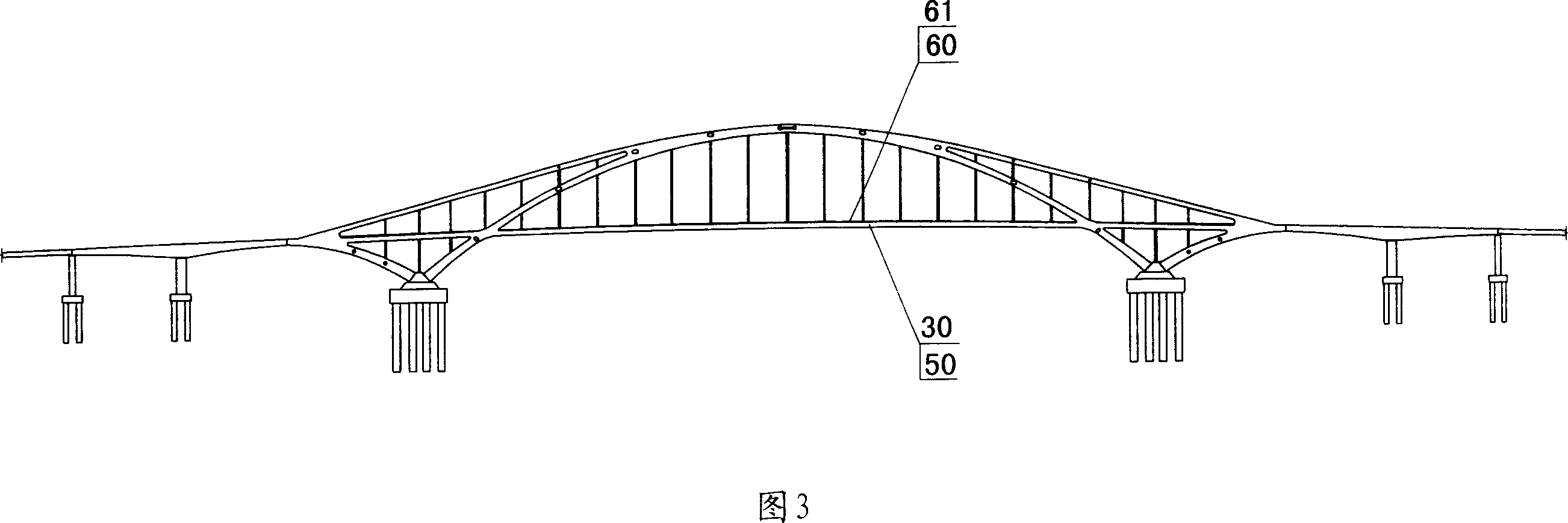

[0018] Figure 3 shows an example of a bridge designed by the applicant using the above-mentioned steel-concrete composite deck technology of the present invention. Referring to Figure 3, the bridge type adopts a steel arch-continuous beam cooperative system bridge with a unique shape and beautiful linear shape. The design load of the bridge: automobile-super class 20, hanging-class-120; local components are checked with the city-A load standard; crowd loads are taken according to the norms; 2×6m sidewalk).

[0019] The total length of the bridge is 1322.2m, and the combined span of the main span is 300m. For the arch ring, C40 concrete is poured into the box. The steel box and the concrete are anchored and connected by PBL shear device; the arch adopts a steel column with an "H" section. The main and auxiliary arch ribs and the side arch ribs are provided with a tubular cross brace every two suspenders (columns), and the whole bridge has 14. The cross braces between the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com