Automatic close-type hinge

An automatic closing and hinge technology, which is used in wing shutters, lighting and heating equipment, door/window accessories, etc., which can solve the problem of rising parts manufacturing and assembly costs, large number of parts, and difficulty in distinguishing whether the hinge is right-opening or not. Left opening specifications and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

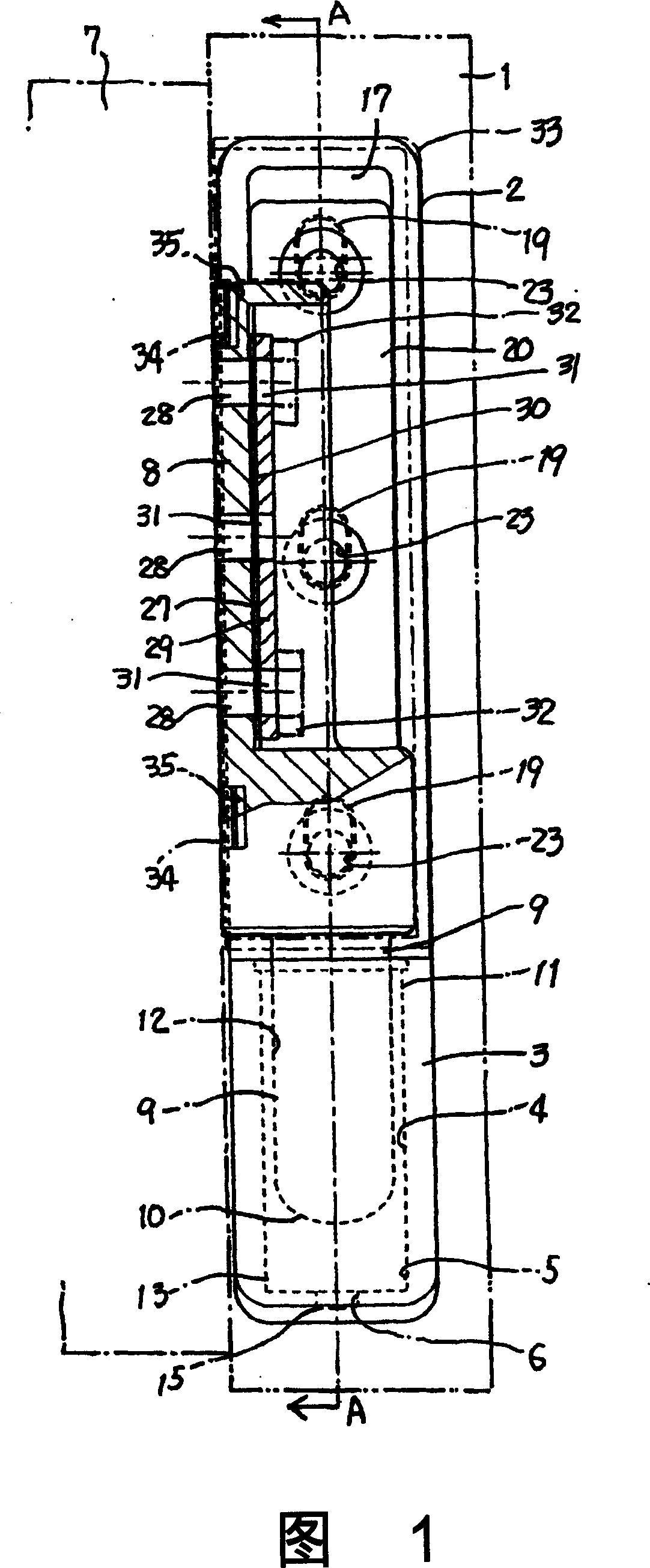

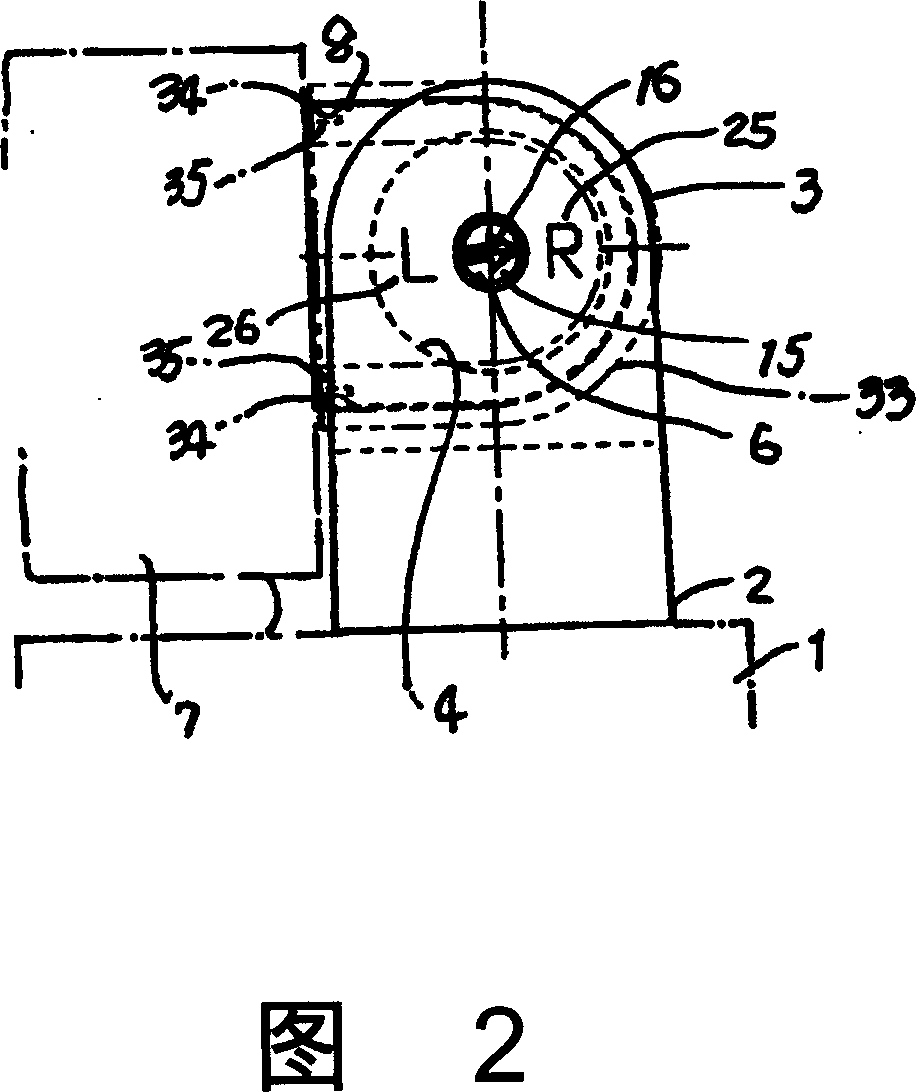

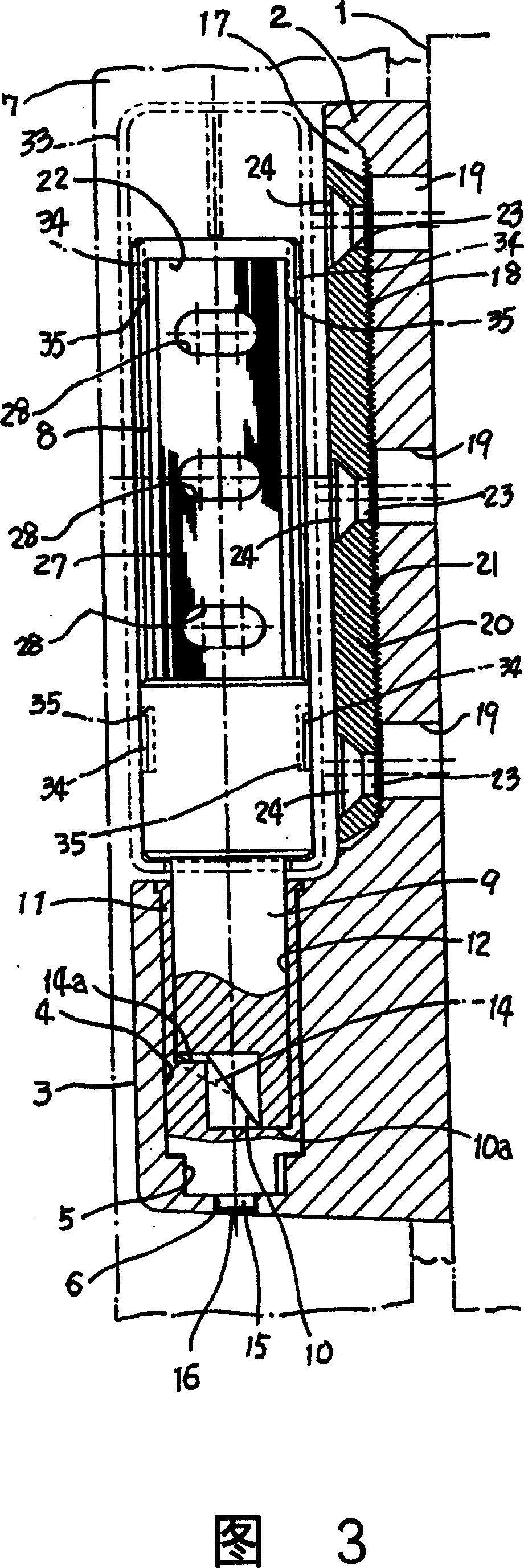

[0048] In the illustrated embodiment, the fixed side wing plate 2 and the movable side wing plate 8 are made of metal, the fixed cam body 11 is made of synthetic resin, and the sliding contact portion of the push-up cam is made of resin and metal. The contact between the cams is made of resin, so there is no wear or significantly reduced wear compared to conventional self-closing hinges.

[0049] After the locking of the door locking handle device installed in addition is released, when the door 7 is rotated to the required angle in the opening direction with the vertical pivot 9 as the center, the drive cam slope 14 of the fixed side wing plate 2 and the vertical pivot The linkage action of the driven cam slope 10 of the shaft 9 makes the vertical pivot 9 and the movable side panel 8 integrated with the vertical pivot 9 rotate and push up to the position shown in FIG. 4 .

[0050] In this open position, if the hand leaves the door 7, the door 7 will automatically close and ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com