Gas-liquid ratio control method of rock core displacement test

A technology of core displacement and gas-liquid ratio, which is applied in earthwork drilling, suspension and porous material analysis, and mining fluid, etc., and can solve the problems of not being able to control the gas-liquid ratio well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

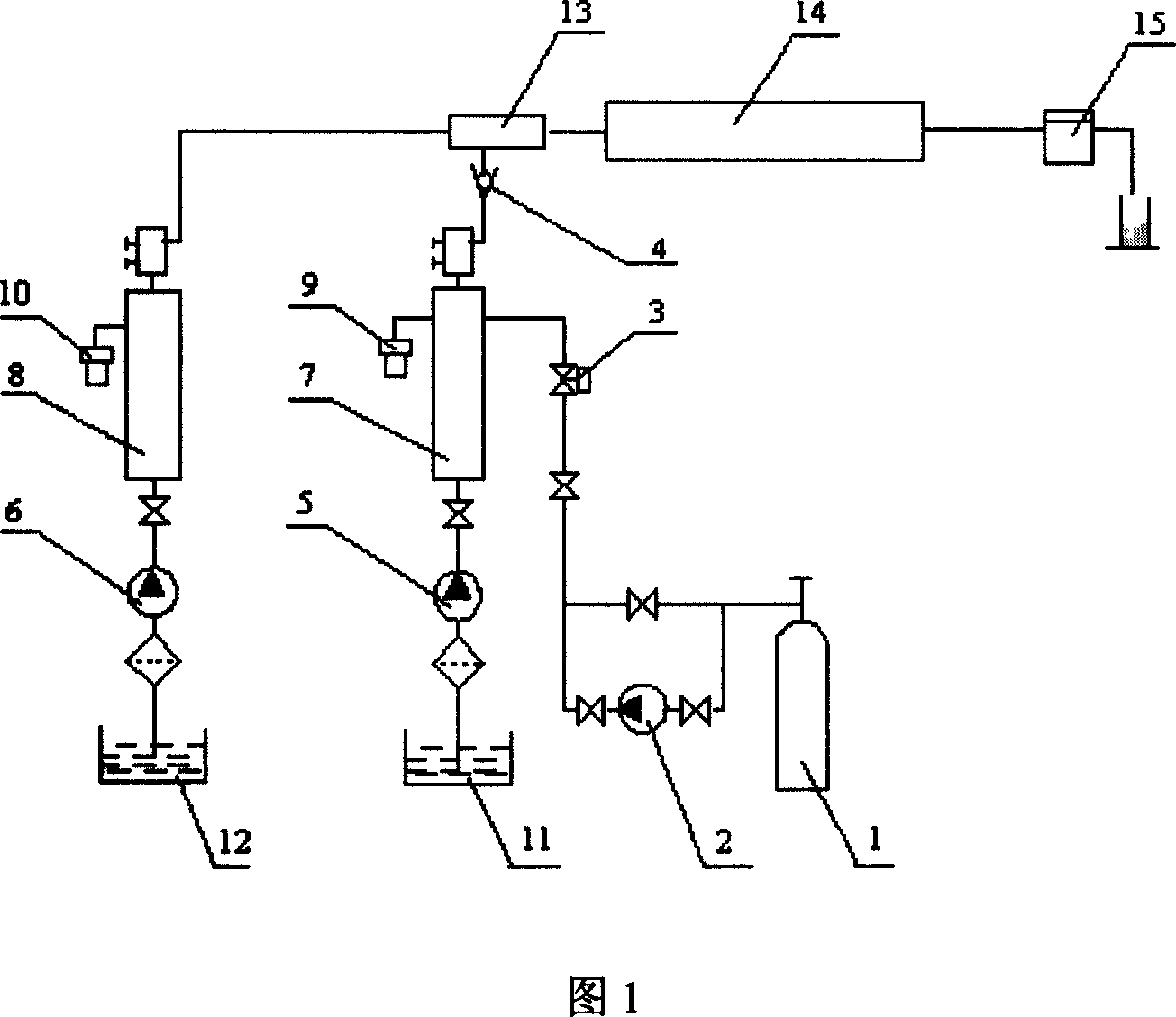

[0010] Example: In the foam flooding experiment, the ratio of gas-liquid injection needs to be controlled to ensure the physical parameters of the foam. There is no gas pressure detection and automatic boosting function in the common control method. In this way, with the injection of foam, the displacement pressure rises, and because the liquid is basically incompressible, the pressurization is rapid, and the liquid pressure reflects the displacement pressure, while the gas has great compressibility, and the pressure rises slowly. In this way, the pressure of the gas will be lower than the pressure of the liquid, resulting in the situation that only the liquid is injected, but the gas cannot be injected, thus changing the injected gas-liquid ratio and foam parameters. With the method of the present invention, when the gas pressure is lower than a certain value of the liquid pressure, the solenoid valve is controlled by the computer to open, and the gas booster pump is automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com