Method of reeling a series of RFID tags and RFID tag roll

A technology of RFID tags and series, applied in the field of RFID tag rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

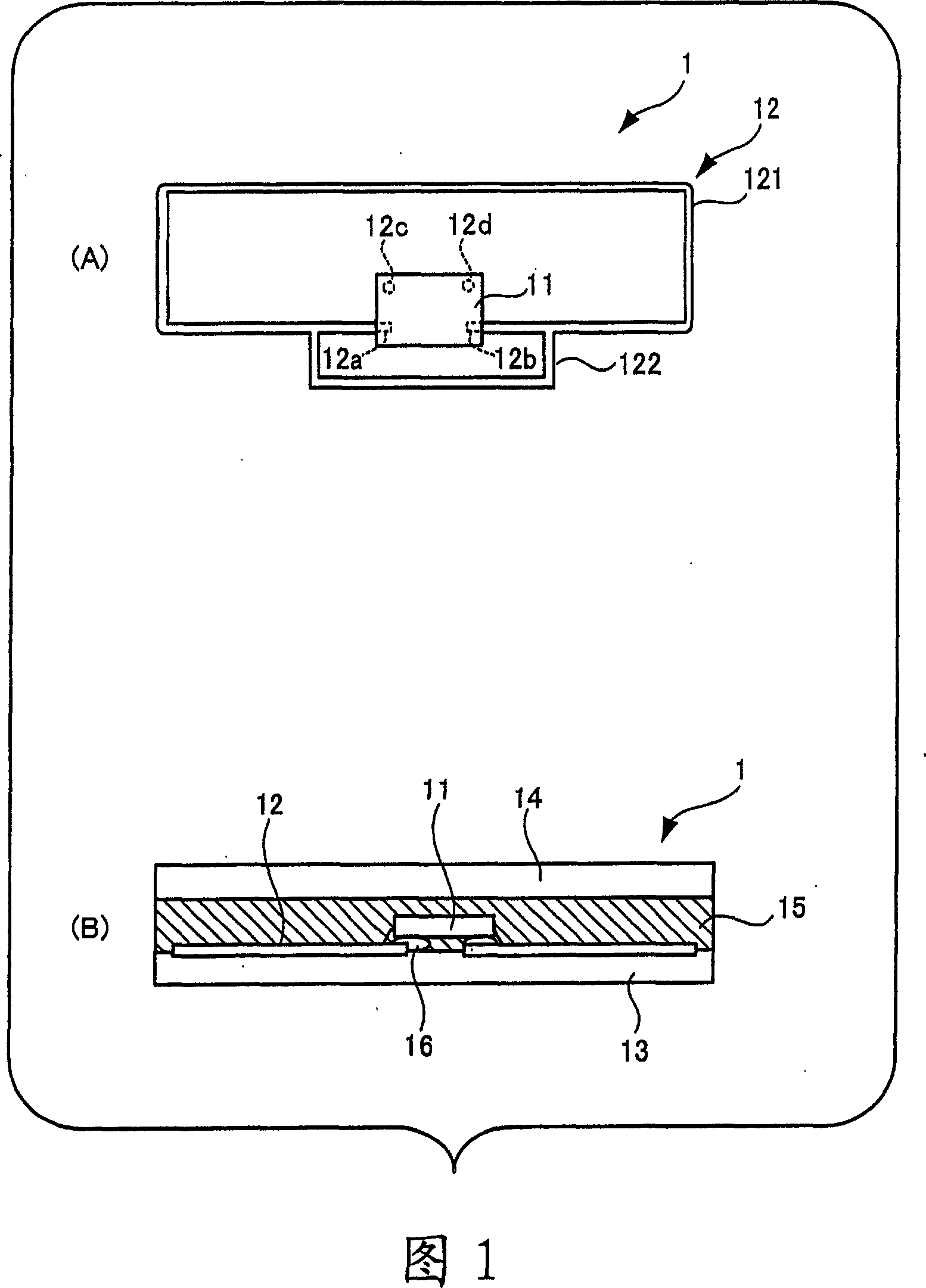

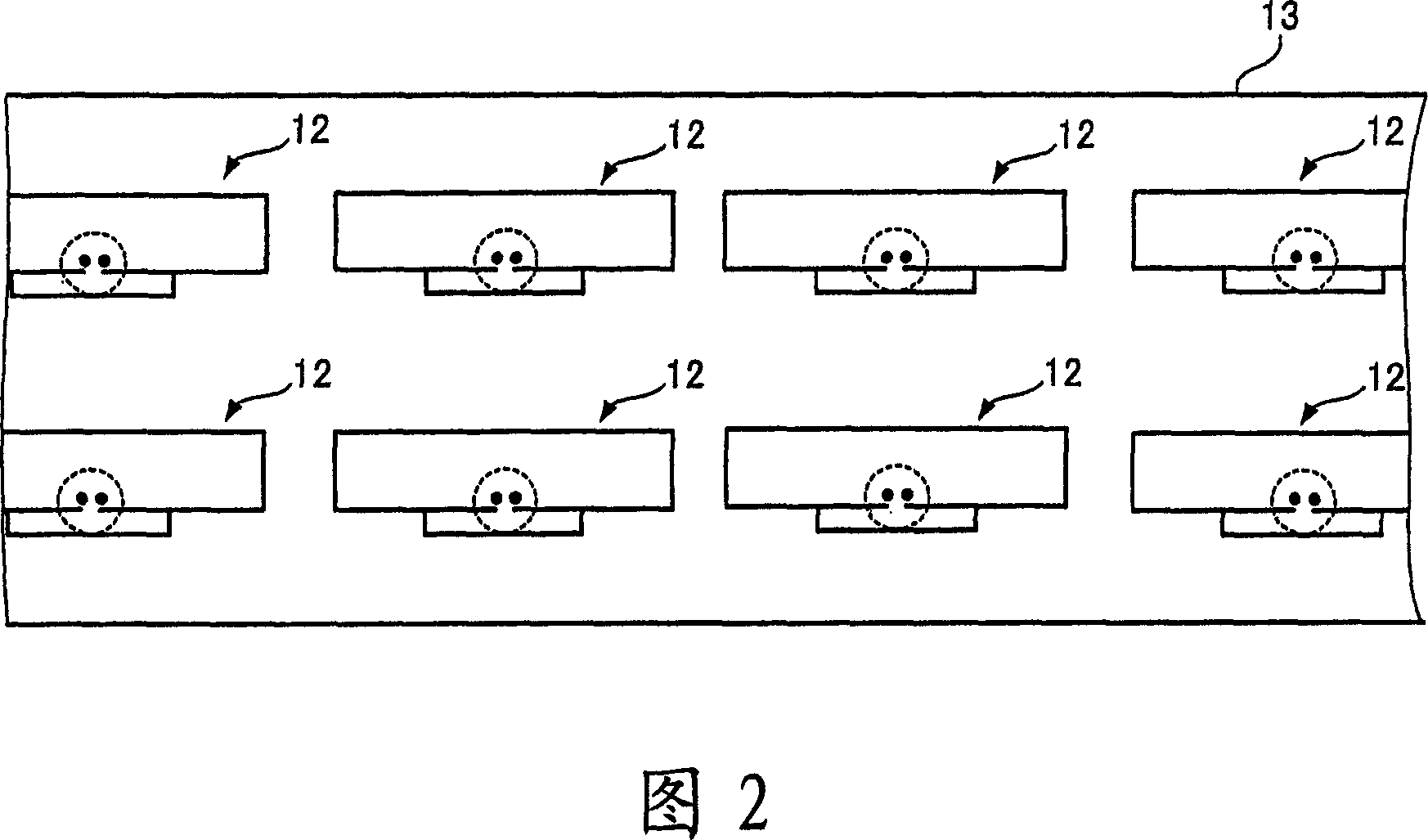

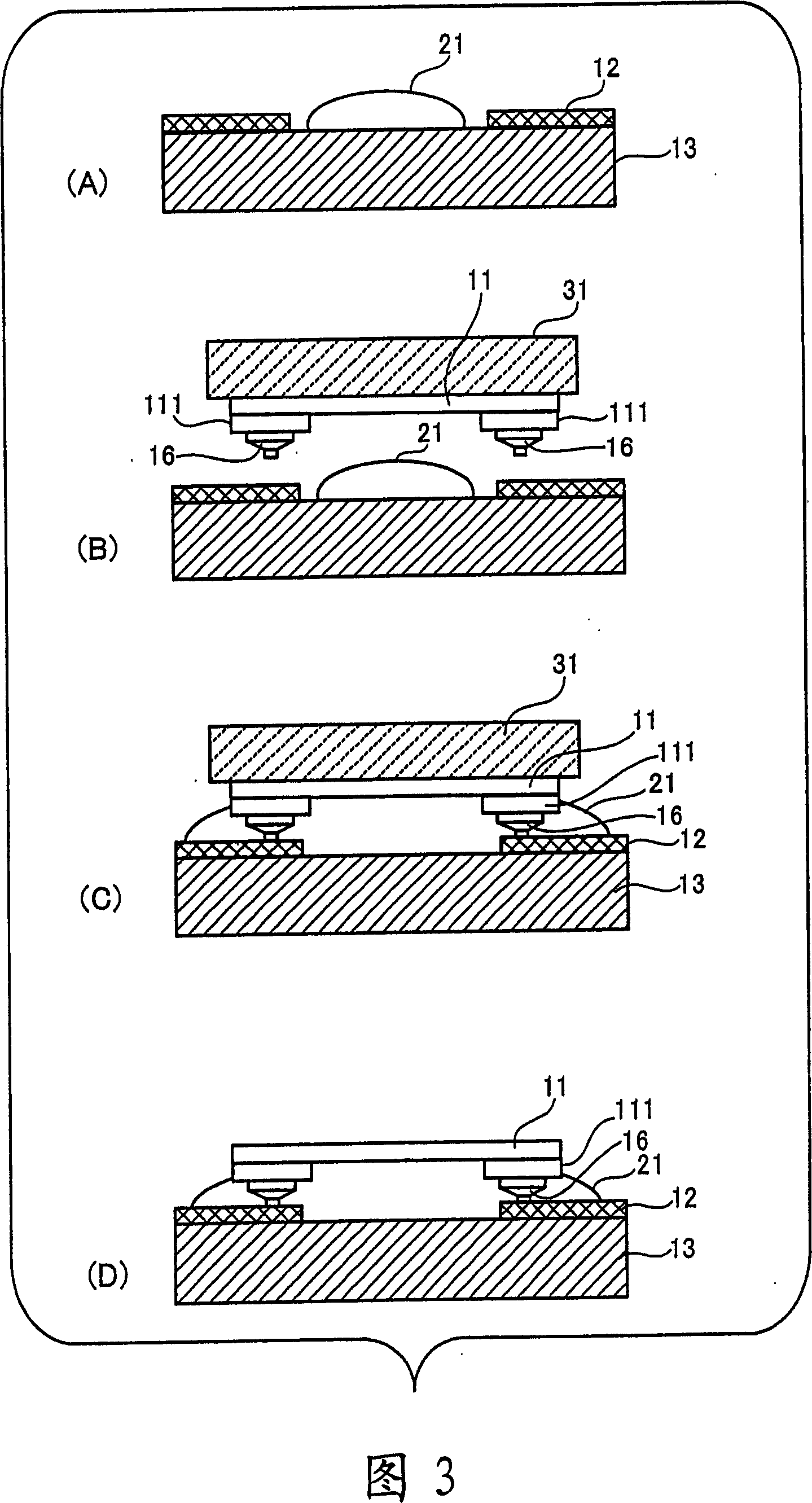

[0040] Exemplary embodiments according to the present invention will be described with reference to the drawings.

[0041] In the exemplary embodiments described below, the RFID tags and the RFID tag family itself are similar to the RFID tags in the prior art described above. Therefore, only the differences from the prior art will be described with reference to FIGS. 1 to 4 and their descriptions.

[0042] Fig. 6 is a diagram showing an RFID tag roll in which the RFID tag series is wound.

[0043] The RFID tag series 100 is wound around a spool core 40 formed of a core material 41 and a stress absorbing material 42 laminated around the core material 41 to form a roll 120 of RFID tags. The diameter of the core material 41 shown in FIG. 6 is smaller than that of the core material shown in FIG. 5 by the portion where the stress absorbing material 42 is placed around the core material 41 .

[0044] In an exemplary embodiment, a material that shrinks and deforms under an external f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com