Cylinder and plain screen combined multipurpose apparatus and manufacture process thereof

A multi-purpose, rotary screen technology, applied in printing process, printing of special varieties of printed matter, screen printing machine, etc., can solve the problems of long production line, fine pattern printing accuracy is not as good as flat screen, incompatibility, etc. The effect of increased output, considerable economic benefits and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

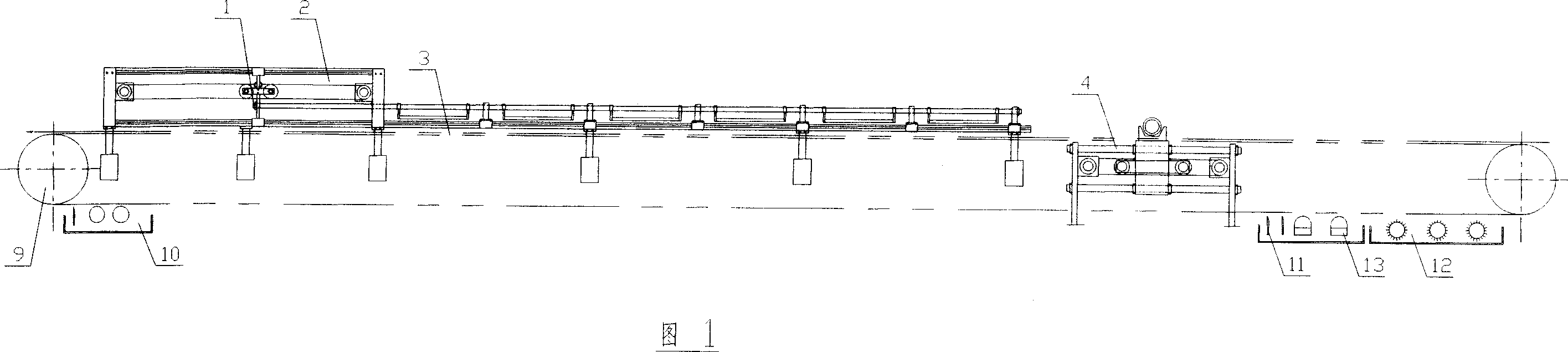

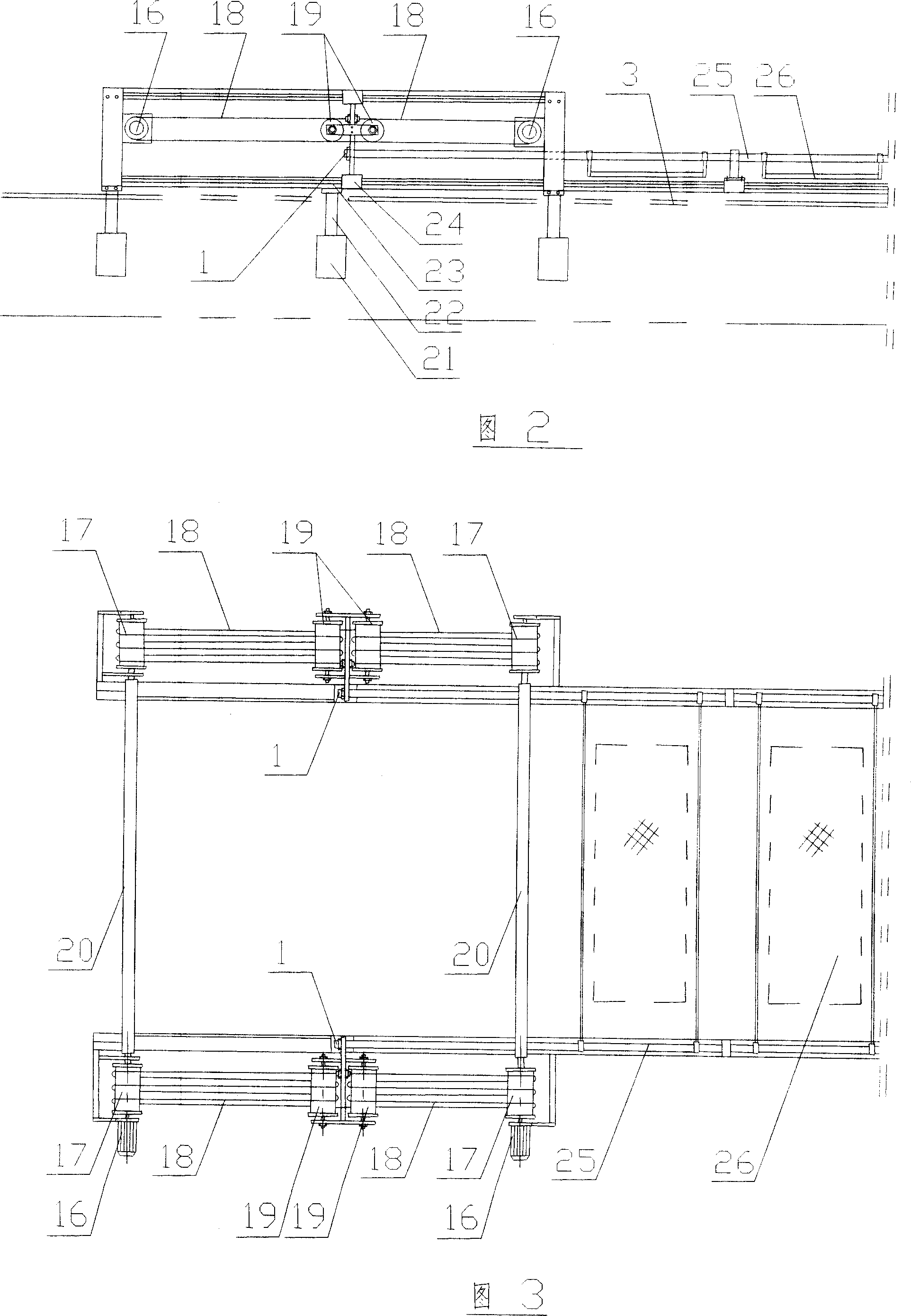

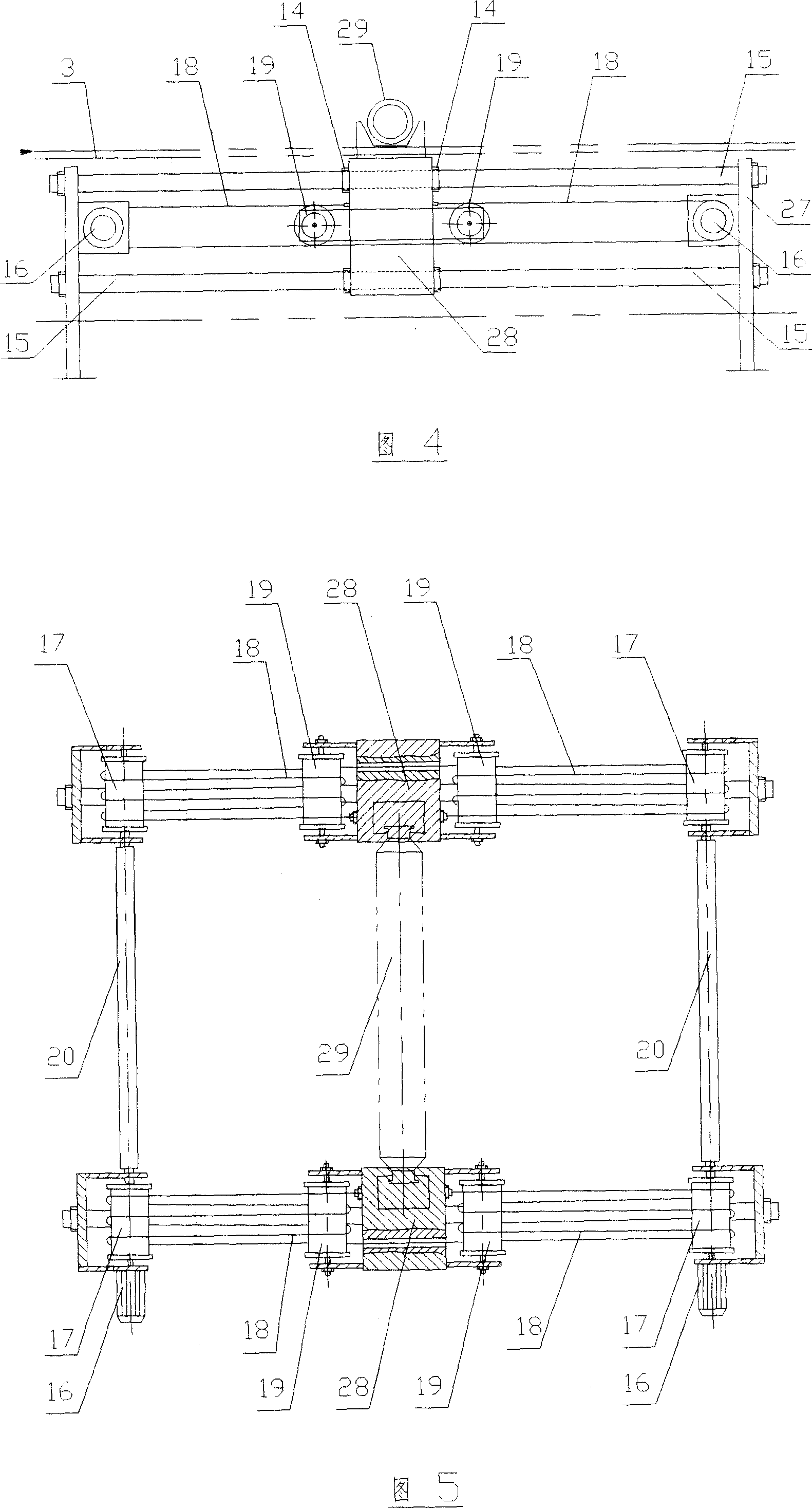

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] The embodiment of multi-purpose equipment combined with rotary screen and flat screen of the present invention (as shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, and Fig. 5) comprises a conduction belt intermittent operation device 3, which is characterized in that, from the conduction belt intermittent operation device From the cloth inlet end to the cloth outlet end, a flat screen printing device 2 and a reciprocating traction parallel moving rotary screen printing device 4 are arranged. The flat screen printing device has a sliding bracket 25 on which a row of flat screen printing plates is installed, a reciprocating traction parallel movement transmission mechanism located at one end of the sliding support, and a lifting bracket 22 for installing the reciprocating traction parallel movement transmission mechanism and the sliding bracket And the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com