Control method of mushed garlic producing process with control on greening and its product

A technology of processing process and control method, which is applied in food preservation, food preparation, food science, etc., can solve the problems of failure to form large-scale production, failure to effectively control the greening phenomenon, and inability to accurately understand the greening reaction of garlic paste Detailed process and other issues to achieve the effect of good nutrition and flavor, good preservation and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

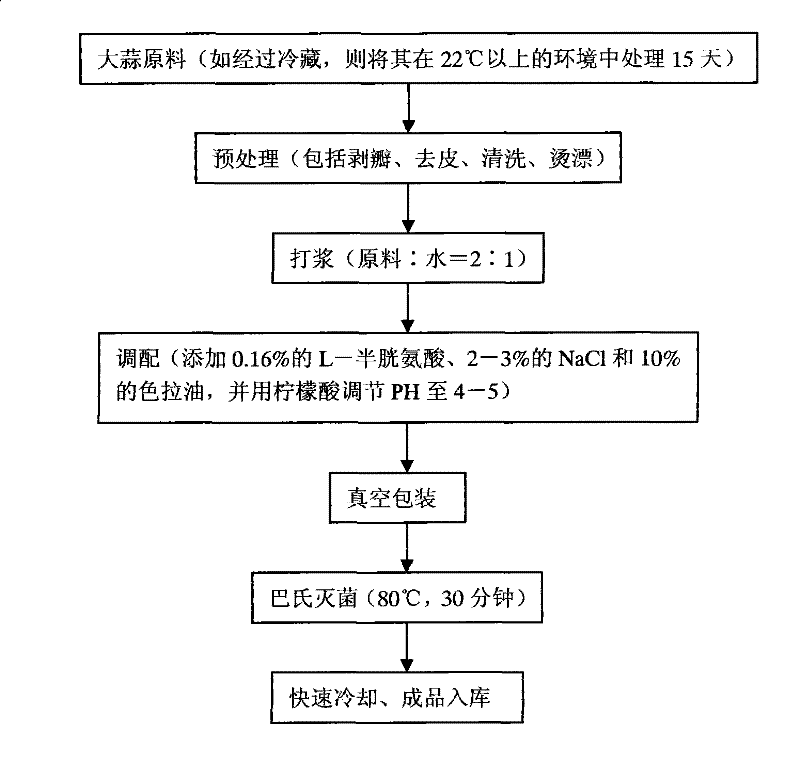

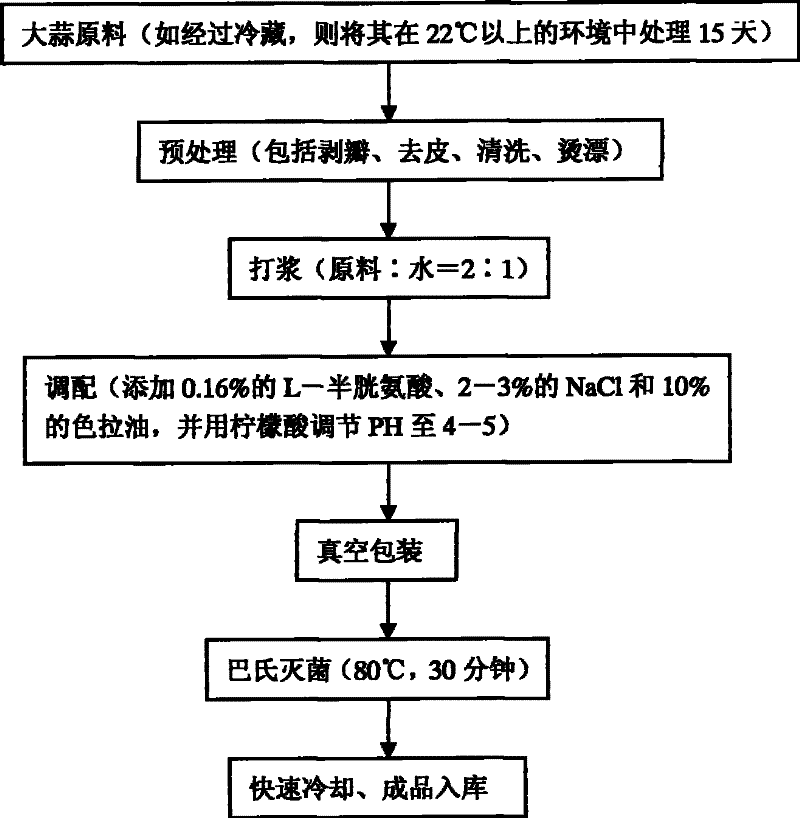

[0020] 1. Pretreatment: Use commercially available fresh garlic without mildew, dryness, germination, and refrigeration as raw materials. After peeling, peeling, cleaning, and blanching (90°C, 3 minutes), drain and dry. Get 100 kg of samples.

[0021] 2. Beating: Add 50 kg of clear water, mix and beat to make the mashed garlic fine and uniform.

[0022] 3. Blending: Add 240 grams of L-cysteine, 3.8 kilograms of salt and 15 kilograms of salad oil to the mashed garlic, stir well and adjust the pH to 4-5 with citric acid.

[0023] 4. Packaging: Vacuum packaging in composite food packaging bags (-0.1MPa, 20 seconds).

[0024] 5. Sterilization: adopt pasteurization (80°C-90°C, 30 minutes), and cool quickly after sterilization.

[0025] 6. Finished product: The finished product is white in color, fine and uniform in texture, and has the unique aroma and taste of garlic. After testing, the physical, chemical and hygienic indicators have all reached the relevant national standards (...

Embodiment 2

[0027] 1. Pretreatment: choose refrigerated (0-4°C) garlic as raw material, and treat it in an environment of 22°C-35°C for 15 days. Then remove the mildewed, shriveled and damaged parts, peel off the skin, wash, blanch (90°C, 3 minutes), and drain to obtain 100 kg of samples.

[0028] 2. Beating: Add 50 kg of clear water, mix and beat to make garlic paste fine and uniform.

[0029] 3. Blending: Add 240 grams of L-cysteine, 3.8 kilograms of salt and 15 kilograms of salad oil to the mashed garlic, stir well and adjust the pH to 4-5 with citric acid.

[0030] 4. Packing: packed in 250g glass bottles, and sealed after degassing.

[0031] 5. Sterilization: adopt pasteurization (80°C-90°C, 30 minutes), and cool quickly after sterilization.

[0032] 6. Finished product: The finished product is white in color, fine and uniform in texture, and has the unique aroma and taste of garlic. After testing, the physical, chemical and hygienic indicators have all reached the relevant nationa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com