Wet-type duster

A wet dust collector and shell technology, applied in the field of dust removal equipment and wet dust collectors, can solve the problems of affecting the filtering effect, inconvenient use, unsatisfactory use stability, etc., and achieve high use stability, good filtering effect, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

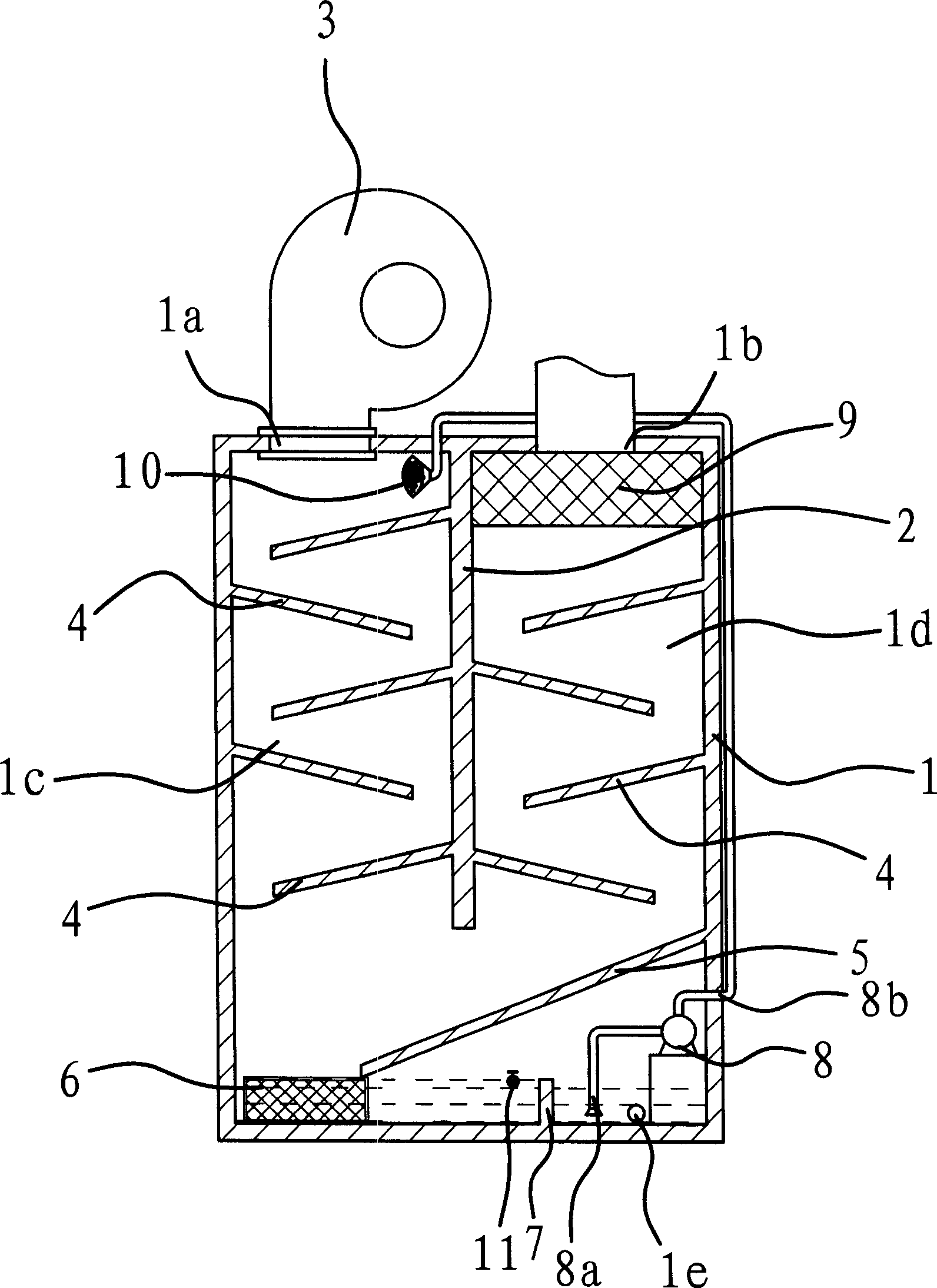

[0023] As shown in the figure, this wet dust collector is used to absorb and filter out the dusty air generated during the operation of the polishing machine, and finally discharge pure air to the outside.

[0024] It includes a housing 1 with an air inlet 1a and an air outlet 1b, a baffle 4 and a partition 2 arranged in the housing 1 . The partition plate 2 divides the interior of the housing 1 into a first cavity 1c and a second cavity 1d, the first cavity 1c and the second cavity 1d are adjacent to each other on the left and right, and the lower parts of the two are connected.

[0025] The air inlet 1a is arranged on the upper part of the first chamber 1c, and the air outlet 1b is arranged on the upper part of the second chamber 1d. A fan 3 and a spray head 10 are provided at the air inlet 1a.

[0026] A number of baffles 4 are arranged in the cavity one 1c, and the baffles 4 are arranged obliquely. The highest point of the baffle 4 is connected to the inner wall of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com