Moving-decoupling space three-freedom connection-in-parallel mechanism

A degree of freedom and parallel technology, applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., can solve the problems of increased difficulty in calibration, limited flexibility and insufficient rotation capacity of the motion platform, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

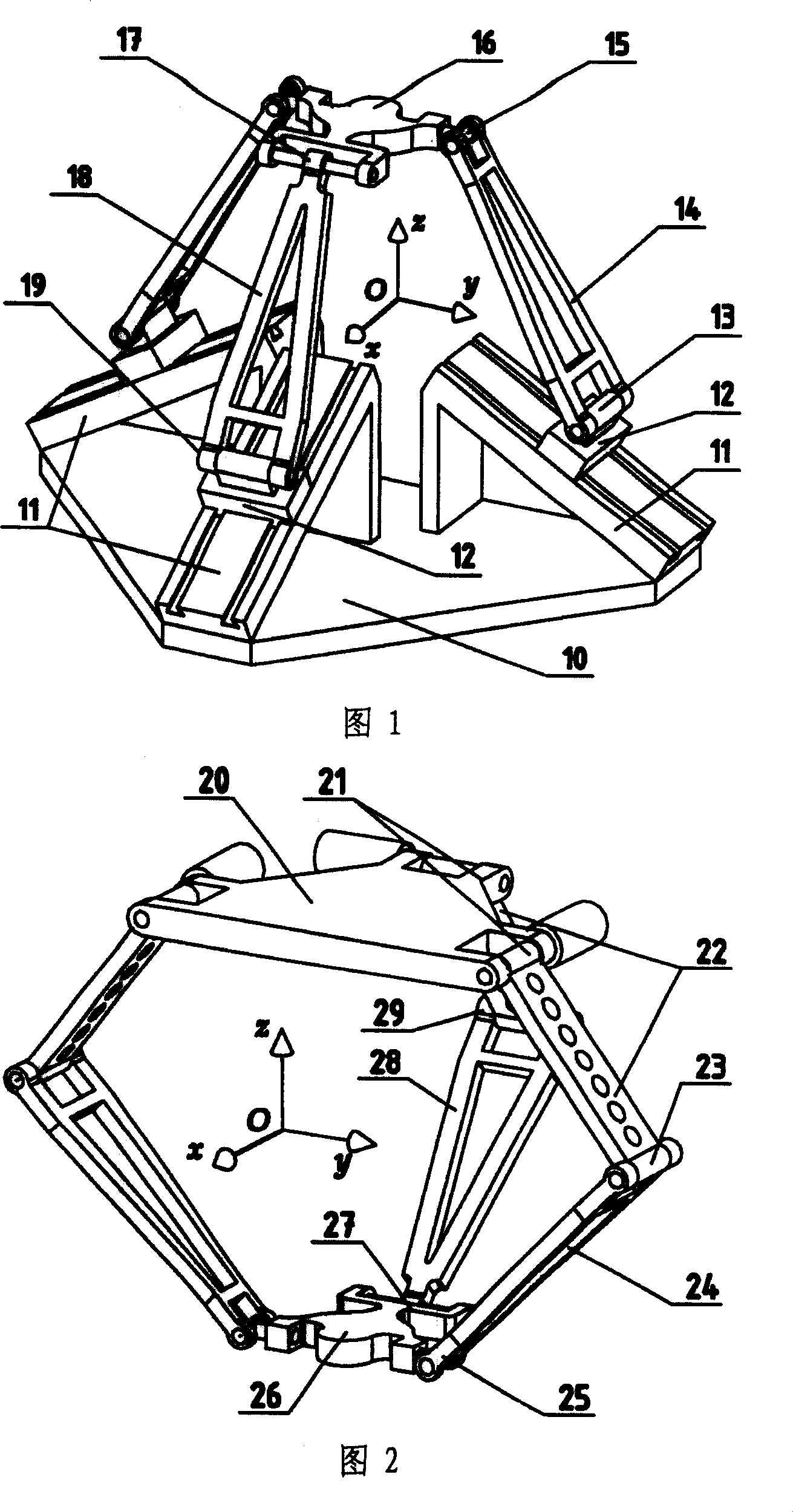

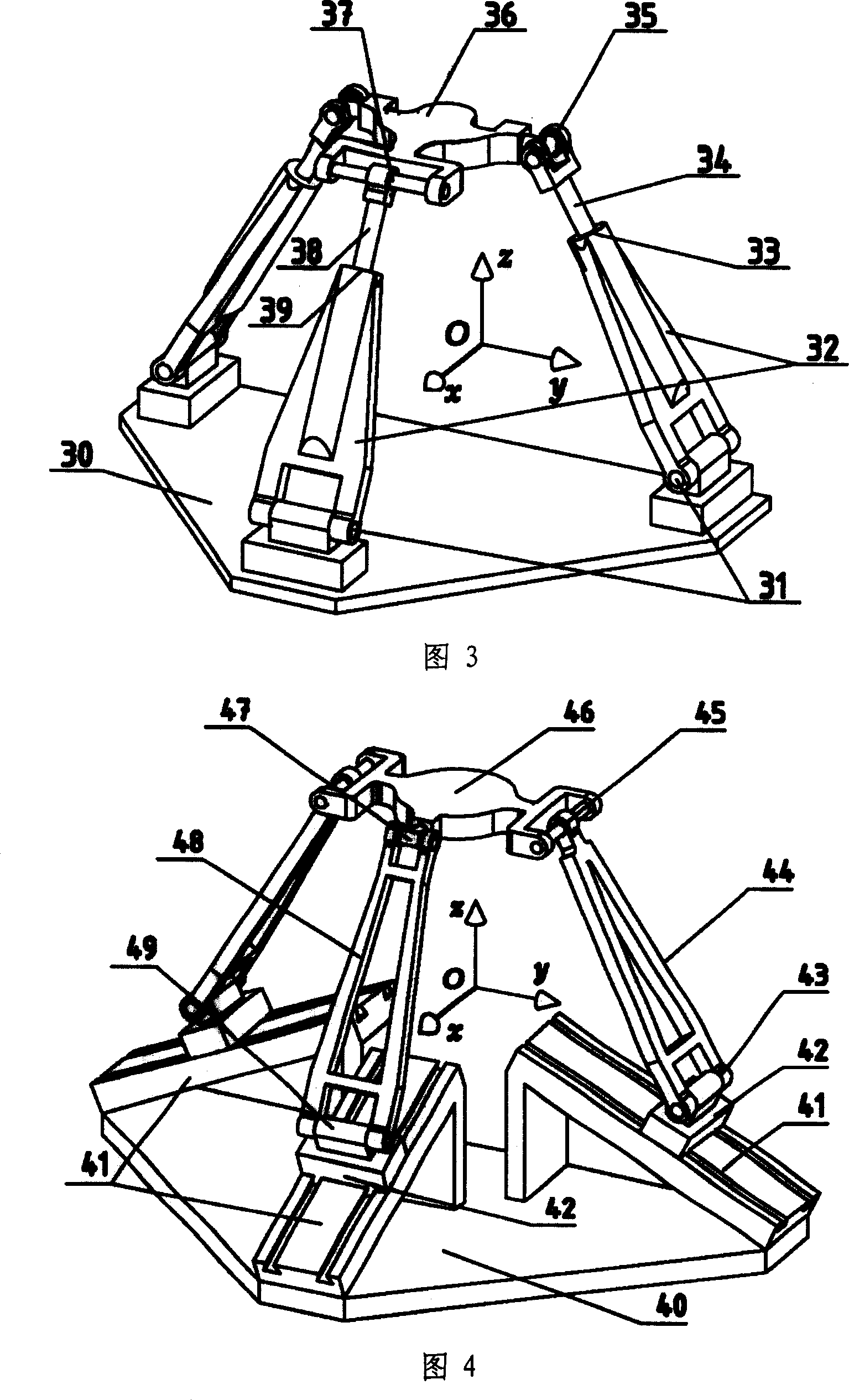

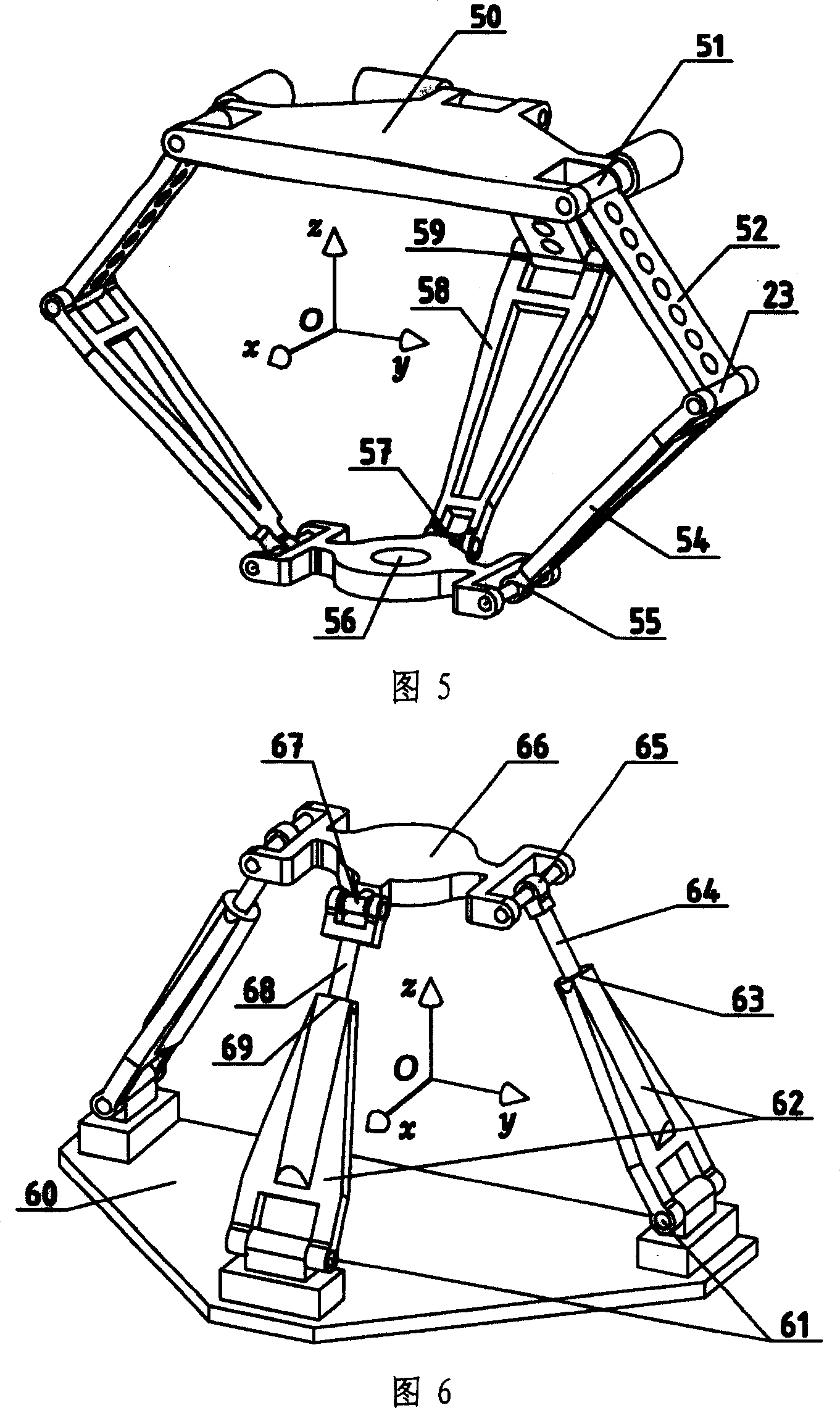

[0018] The first embodiment of the three-degree-of-freedom parallel mechanism of the present invention is shown in FIG. 1 . The mechanism includes a triangular moving platform 16 , a fixed platform 10 , and three branches connecting the moving platform 16 and the fixed platform 10 . The fixed platform 10 is a generalized platform, including three inclined guide rails 11 fixed on the platform 10 . Among the three branches, two branches are the same, and the longitudinal symmetry axes of these two branches are located in the same plane, and both include: input slider 12, truss member 14, and kinematic pair; the kinematic There are three pairs, one is the moving pair a connected between the input slider 12 and the inclined guide rail 11, the other is the rotating pair 13 connected between the input slider 12 and the truss bar 14, and the other is connected to the moving pair a. Universal or ball joint 15 between platform 16 and truss member 14 . Another branch comprises: input s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com