Method and system for determining a cornering angle of a tyre during the running of a vehicle

A technology of vehicle control system and turning angle, which is applied in the direction of automobile tire testing, tire measurement, vehicle parts, etc., and can solve the problem of not being able to easily turn the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

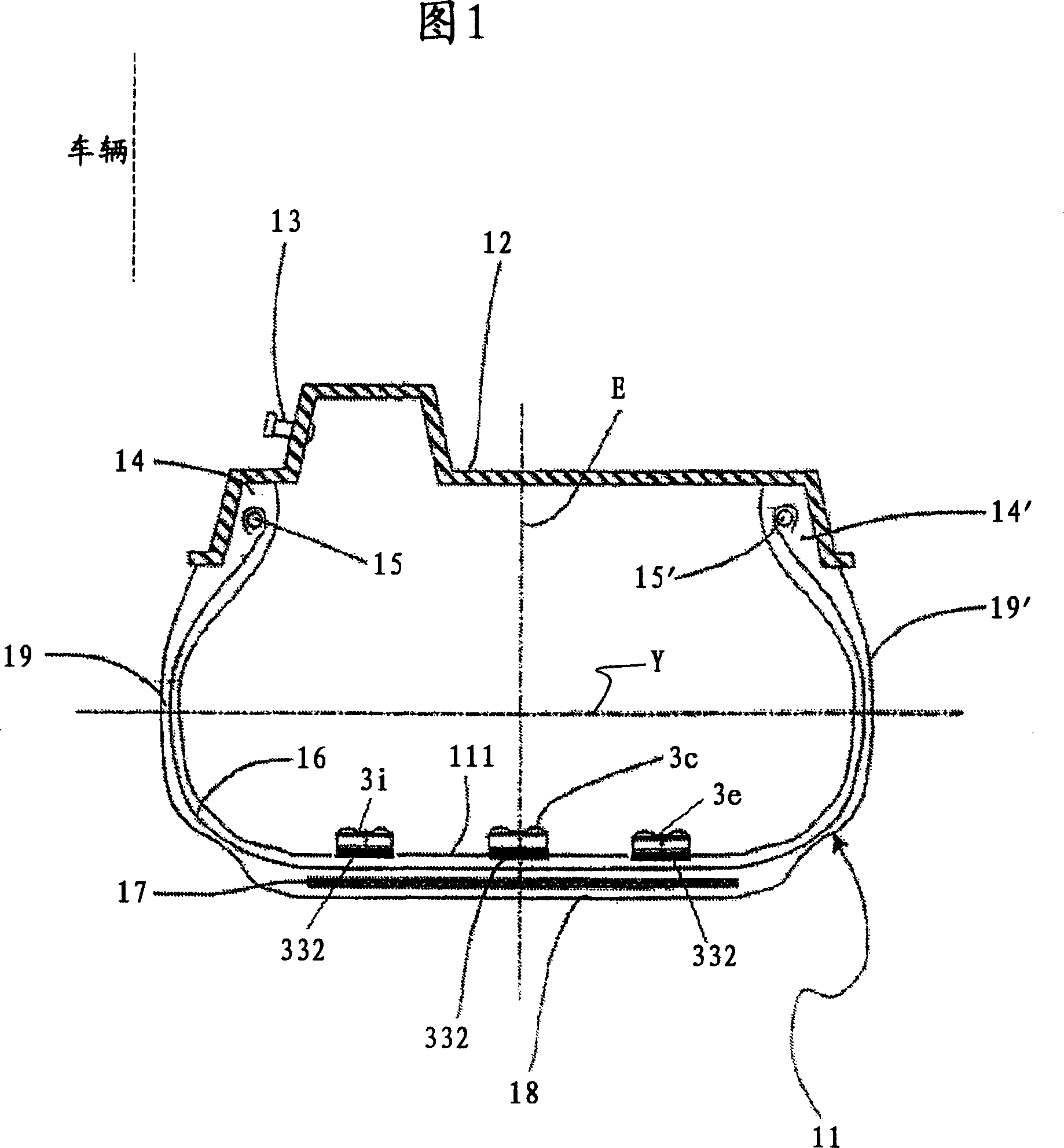

[0059] FIG. 1 shows a cross-sectional view of a wheel comprising a tire 11 and a supporting rim 12 . The tire 11 shown in Figure 1 is of the type conventionally called "tubeless", ie it does not contain an inner tube. The tire can be inflated by means of an inflation valve 13 located, for example, on the channel of said rim 12 . The tire is mounted on a vehicle (not shown).

[0060] The tire 11 comprises a carcass 16 terminating in two beads 14 and 14 ′, each formed along the inner periphery of the carcass 16 for securing the tire 11 to a respective supporting rim 12 . The tire beads 14, 14' comprise respective reinforcing annular cores 15 and 15' called tire bead cores. The carcass 16 is formed by at least one reinforcing ply comprising fabric or metal cords extending axially from one tire bead 14 to the other 14' in a helical tubular configuration and having their ends connected to Each tire beading core 15 and 15' is associated. In tires of the type known as radial tyre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com