Vibration suppression method for stopping process section of industrial robot

An industrial robot and vibration suppression technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as time-lag joint ends and time delays, and achieve the effects of easy modularization, convenient use, and elimination of jitter and residual vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The method of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0060] The active vibration suppression method during the stopping process of the industrial robot of the present invention not only ensures the timeliness of stopping, but also greatly reduces the process vibration and residual vibration. , easy to modularize, easy to use and cross-platform transplantation.

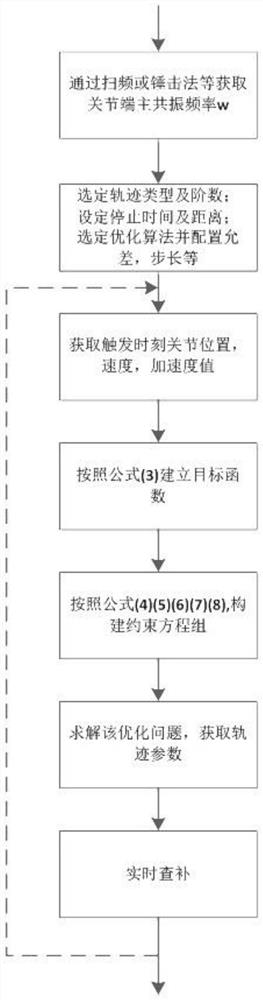

[0061] Refer to attached figure 1 , the concrete steps of the inventive method are as follows:

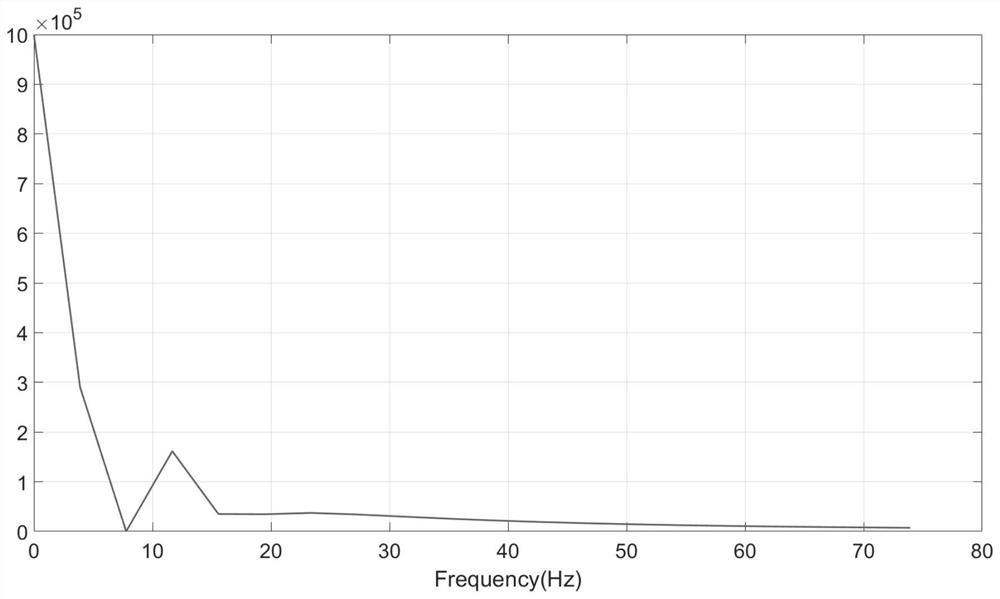

[0062] The idea of the invention is used to design the stop processing module of the industrial robot, which can be used for the control of each joint of the robot respectively. For example, for joint 1, its main resonance frequency point obtained by frequency sweep method is ω=7.5Hz, therefore, the selected frequency range to be filtered is ω 1 =7Hz to ω 2 = 8Hz.

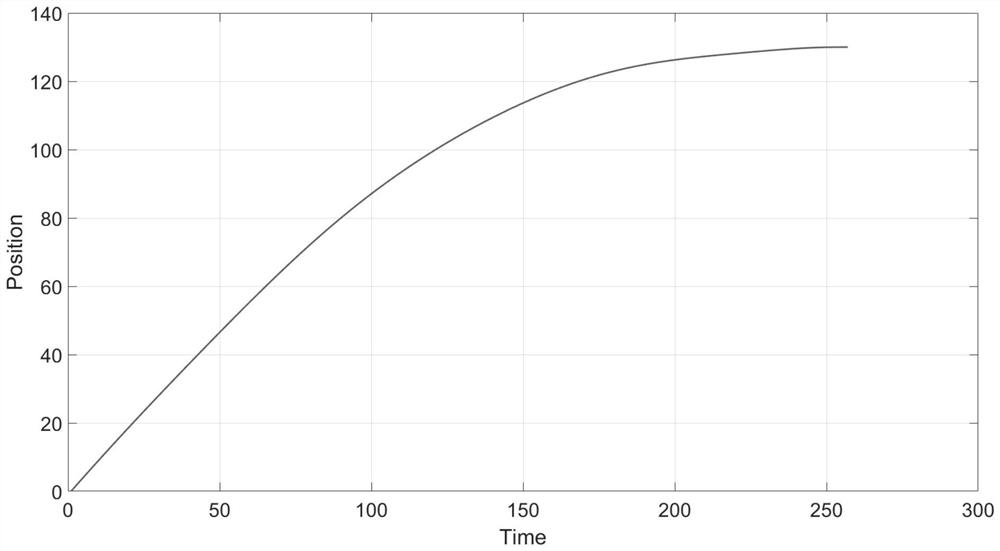

[0063] Select a polynomial of degree 12 as the planning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com