Tube expanding device

一种辊子、框架的技术,应用在扩管装置领域,能够解决操作者负担大、连接部松动、振摆旋转等问题,达到缩短扩管时间、减轻负担、提高作业效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

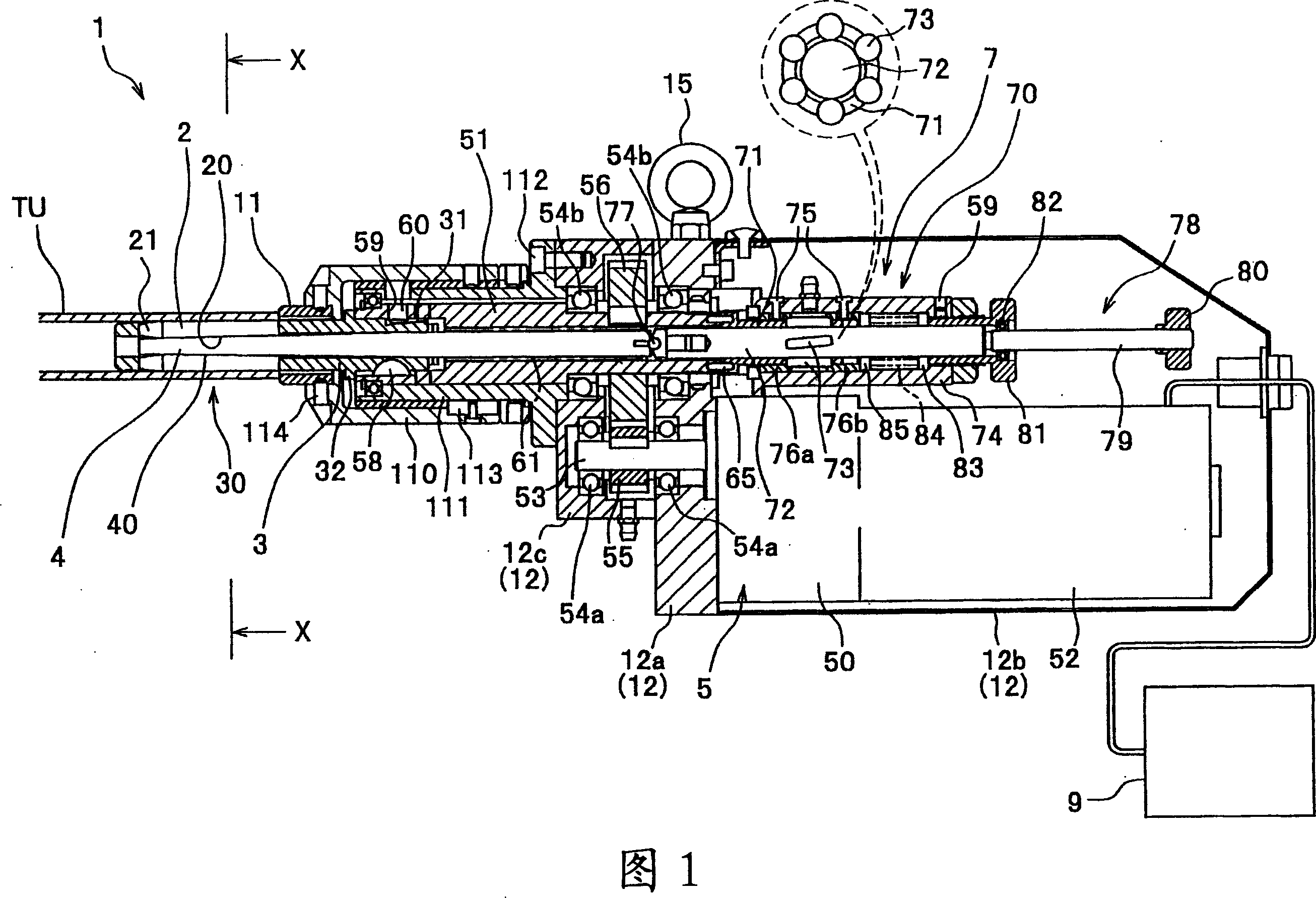

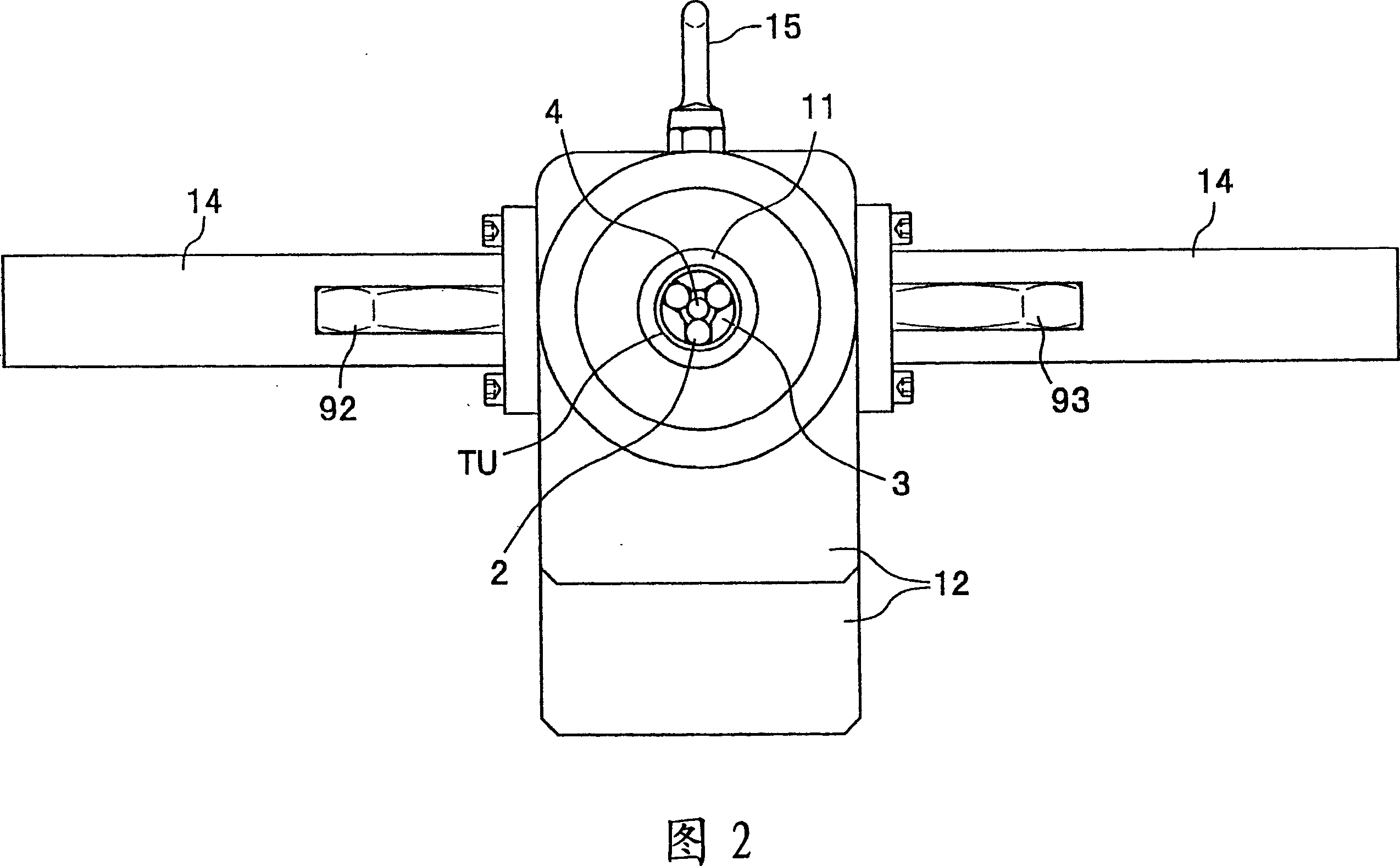

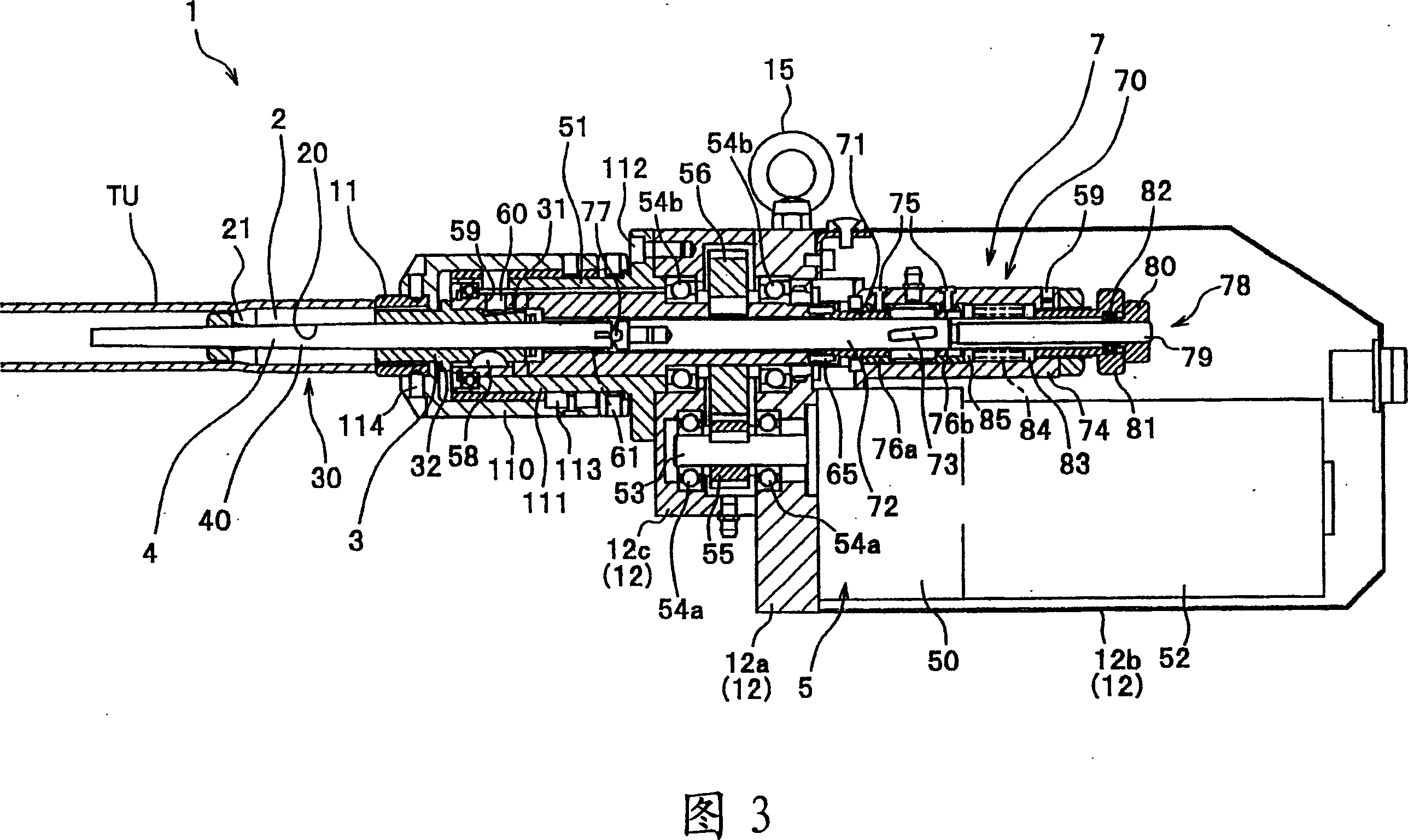

[0062] Hereinafter, the best mode for carrying out the present invention will be described in detail with reference to the drawings.

[0063] Fig. 1 is a sectional view showing the best mode of the pipe expanding device for implementing the present invention, Fig. 2 is a front view showing the best mode of the pipe expanding device for implementing the present invention, and Fig. 3 is a diagram showing the embodiment of the present invention. 4 is a cross-sectional view taken along line X-X in FIG. 1 , and FIG. 5 is a configuration diagram showing a control member of the pipe expanding device according to this embodiment.

[0064] In this embodiment, the distal end side (left side in FIG. 1 ) of the expansion frame inserted into the tube as the member to be expanded is defined as the front side, and the base end side (right side in FIG. 1 ) is defined as the rear side. , for illustration.

[0065] As shown in FIG. 1 , the pipe expanding device 1 of this embodiment includes: a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com