Mineral shovel loader for lane

A technology of shovel loader and ore, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., which can solve the problems of high labor intensity, low efficiency and high risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

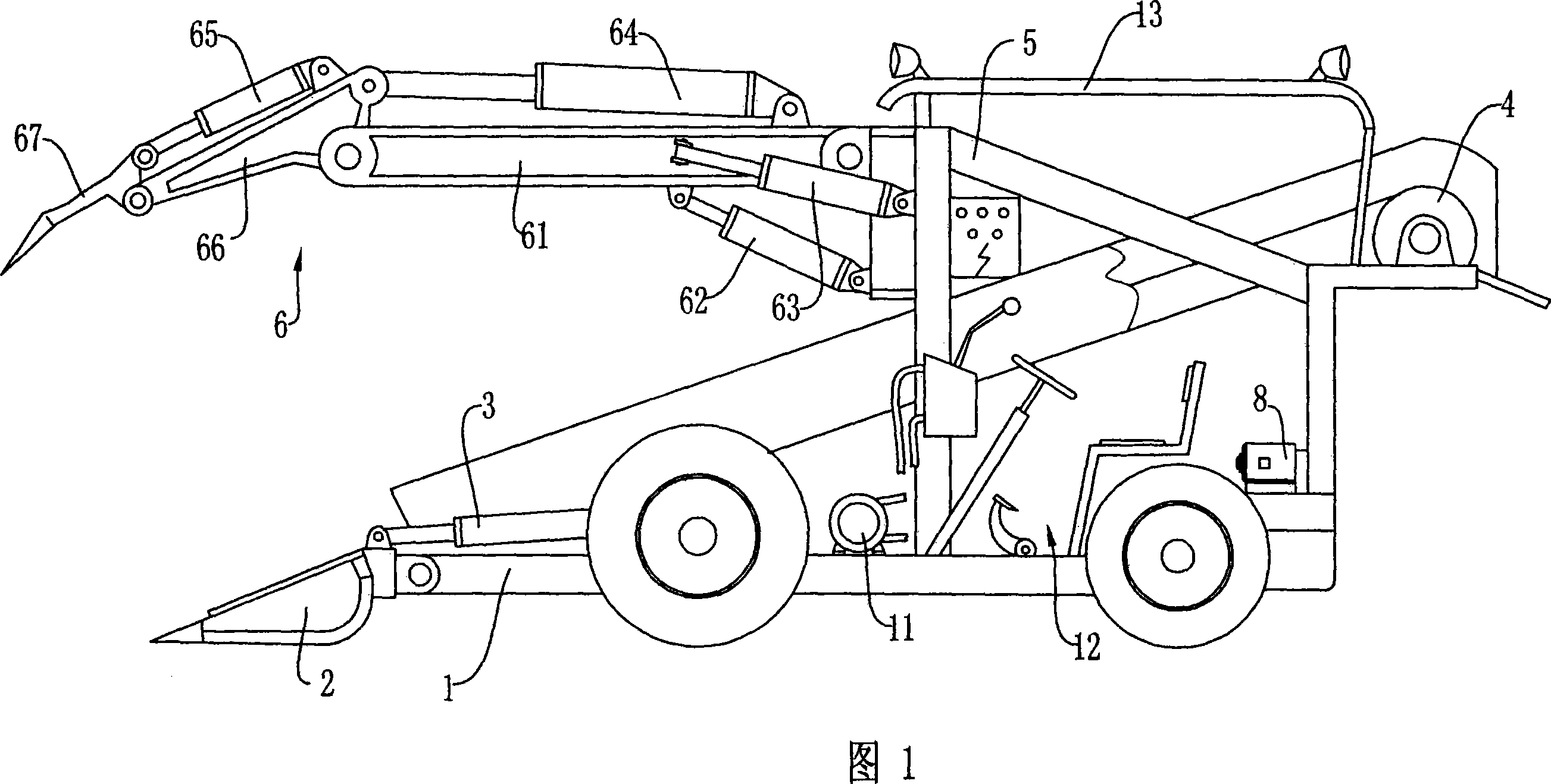

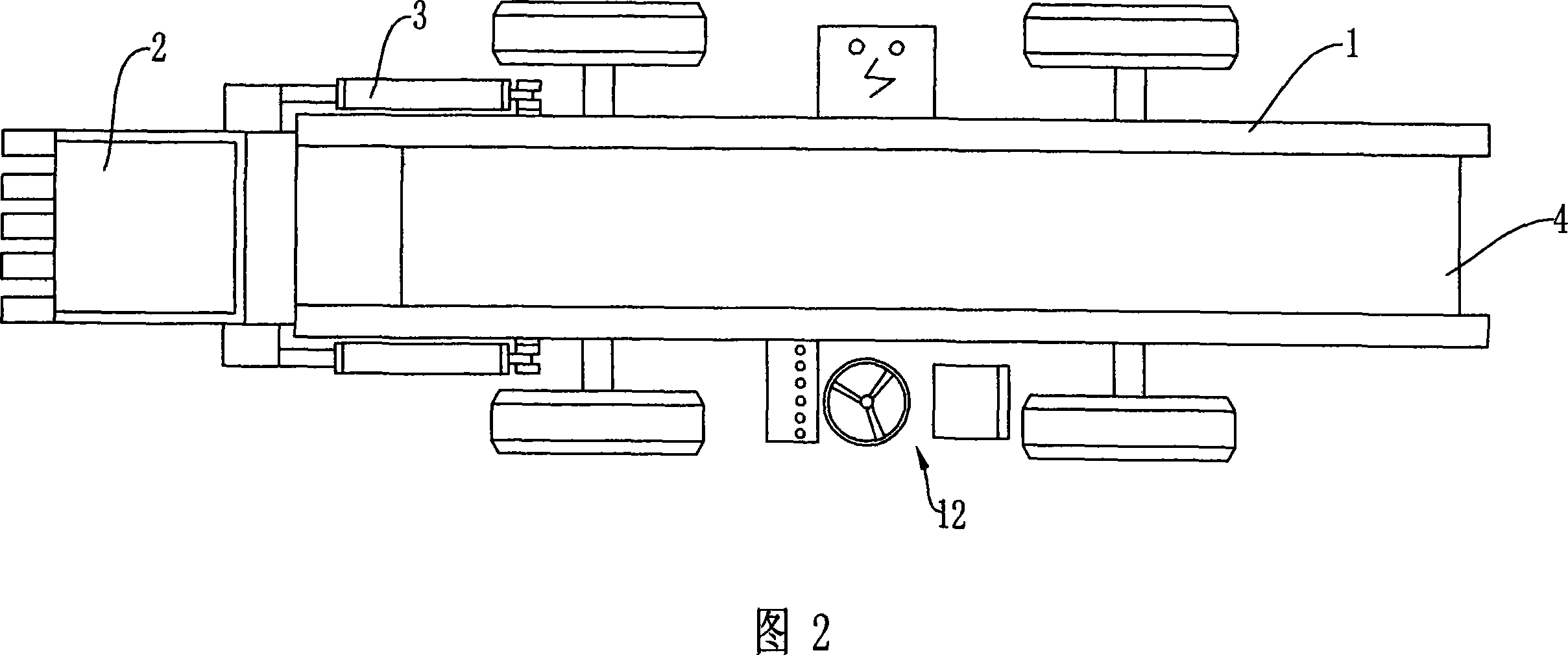

[0012] An ore shovel loader for a roadway, as shown in Figure 1, includes a traveling device 1 driven by a power device, a bucket 2 hinged at the front end of the traveling device 1, and installed between the bucket 2 and the traveling device 1 The first hydraulic cylinder 3; the conveying device 4 for transporting the ore scooped up by the bucket 2 from the front end of the traveling device 1 to the rear end of the traveling device 1, and the conveying device 4 is installed on the traveling device 1; fixed The frame 5 connected to the walking device 1 is installed on the rack 6, and the scraping device 6 is located above the bucket 2 and the conveying device 4.

[0013] Described pick-up device 6 comprises the big arm 61 that is hinged on described frame 5, the small arm 66 that is hinged on described big arm front end, the pick-up tooth 67 that is hinged on described small arm front end; And is hinged on frame 5 and The second hydraulic cylinder 62 that can make the boom 61 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com