Device and method for fixing an impeller to a shaft

A technology of impeller and fixed parts, which is applied to parts of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc., can solve the problems of labor-intensive, high-cost, and time-consuming processing technology for threaded connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

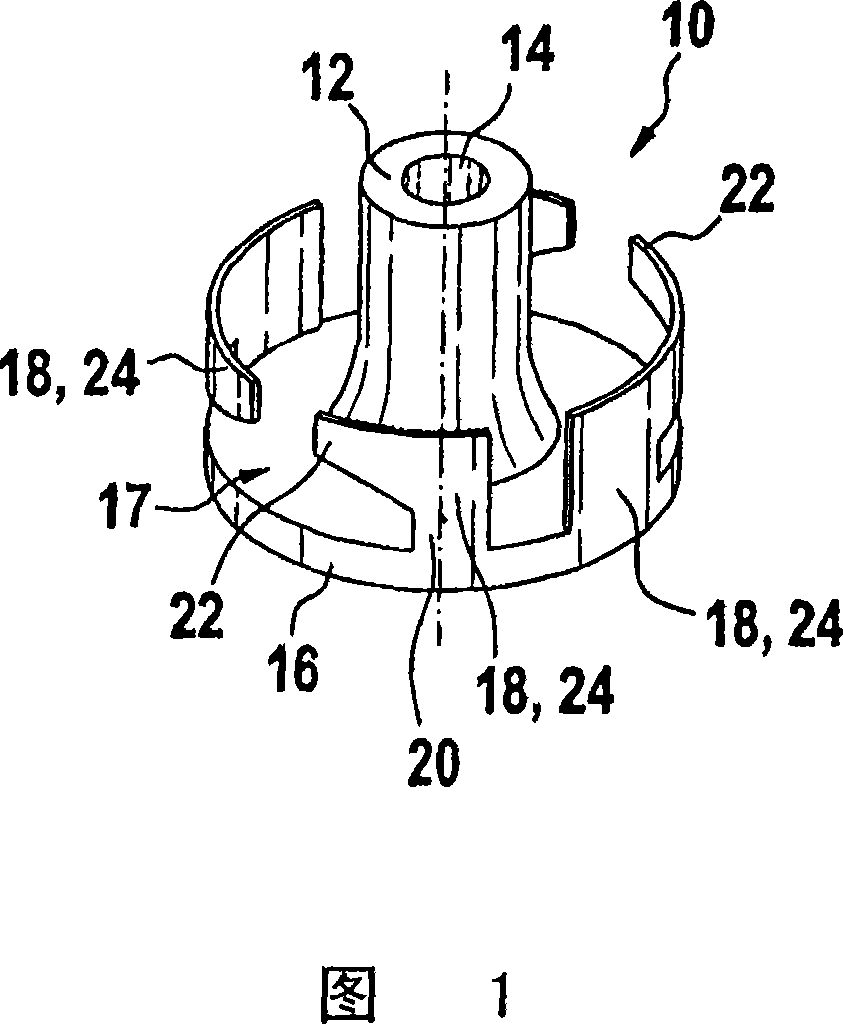

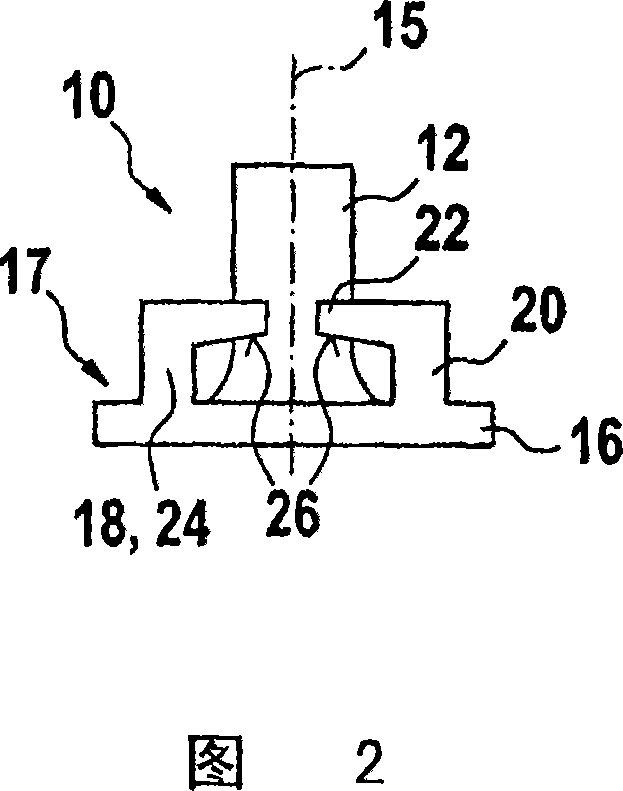

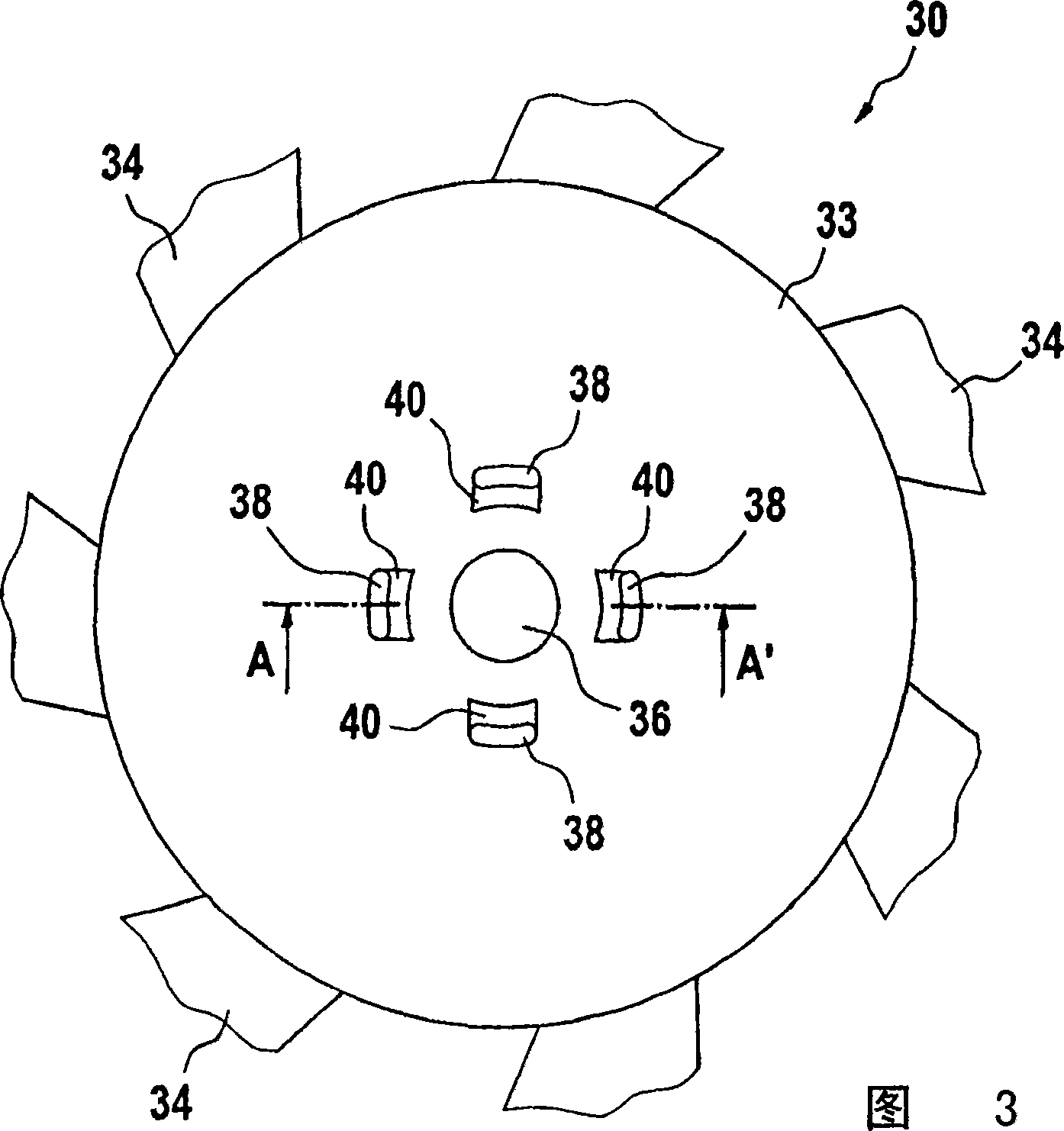

[0031] FIG. 1 shows a possible embodiment of a clip 10 according to the invention for fastening an impeller on a shaft. The preferably one-piece clamp 10 is extruded from steel sheet, but can also be made of other metallic or non-metallic materials, such as plastic. In this case the clip is advantageously produced by injection molding.

[0032]The clip 10 has an essentially cylindrical hub 12 in its center, which has a through-opening 14 for receiving a shaft. The clamp 10 is fixed on the shaft, such as the drive shaft of the motor, by means of the hub 12 , such as being compressed or shrink-fitted. In an alternative embodiment of the device according to the invention, instead of the through hole 14 , it is also possible, for example, for the clip to have a blind hole in the hub for receiving the shaft.

[0033] At its axial end corresponding to the lower end in FIG. 1 , the clip 10 according to the exemplary embodiment in FIG. 1 has a plate-shaped widening 16 which is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com