Belt locking mechanism, head supporting body installation structure, seat main body installation structure and shopping vehicle

A support body and shopping cart technology, applied in the field of shopping carts, can solve the problems of complex structure, high manufacturing cost, complicated assembly operation, etc., and achieve the effects of simple assembly, reduced manufacturing cost and maintenance cost, and simplified manufacturing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0075] Embodiments of the present invention will be described below with reference to the drawings.

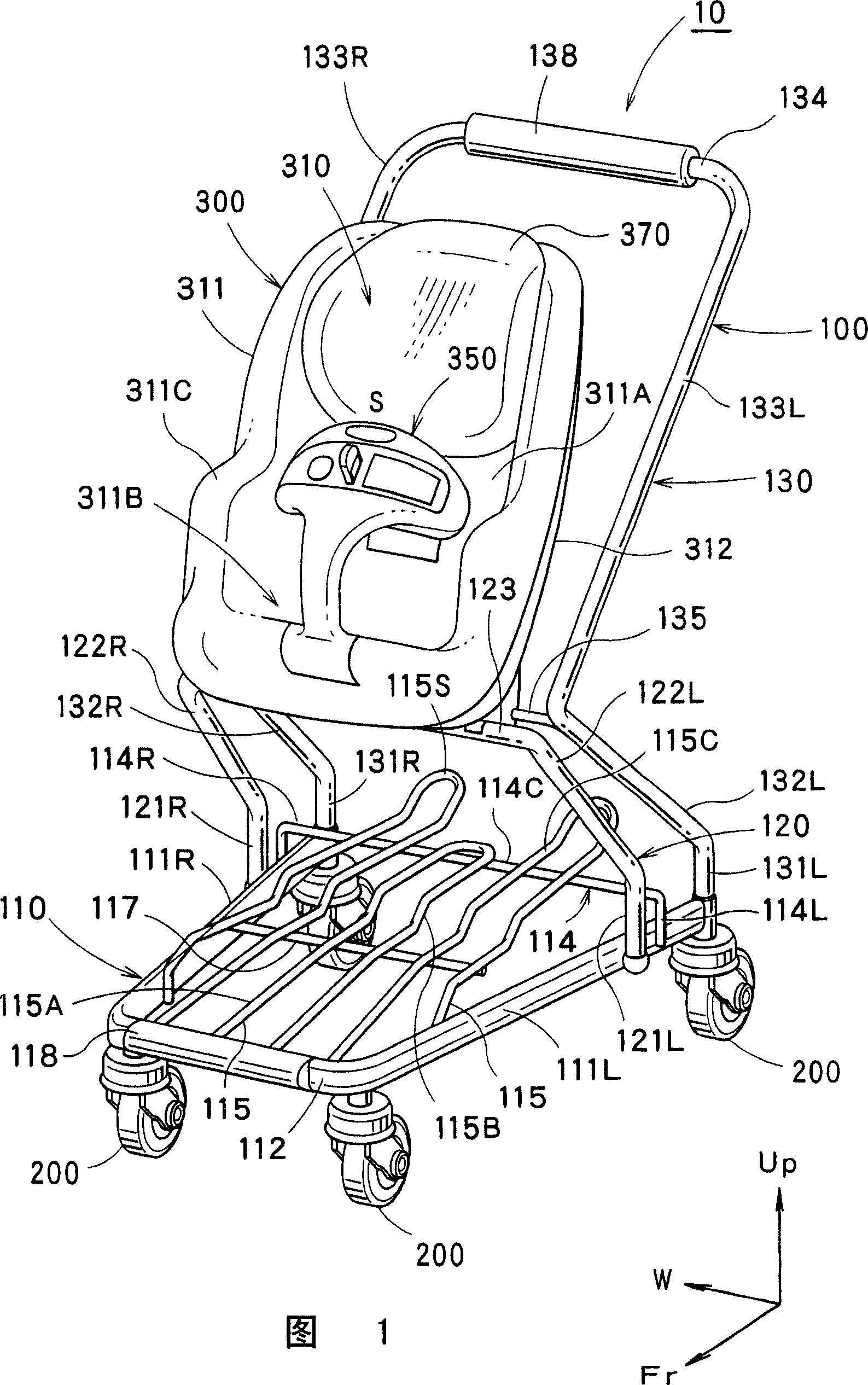

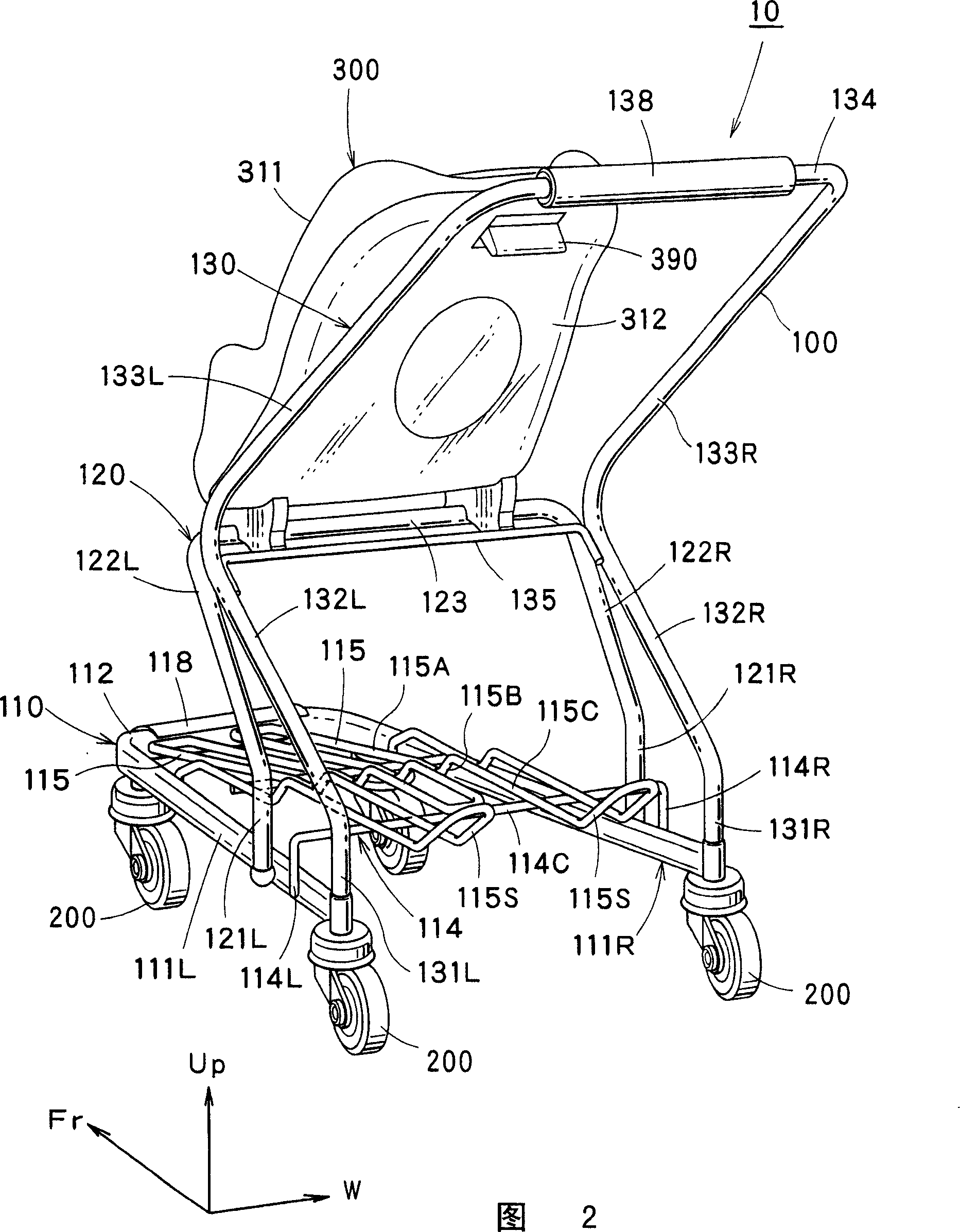

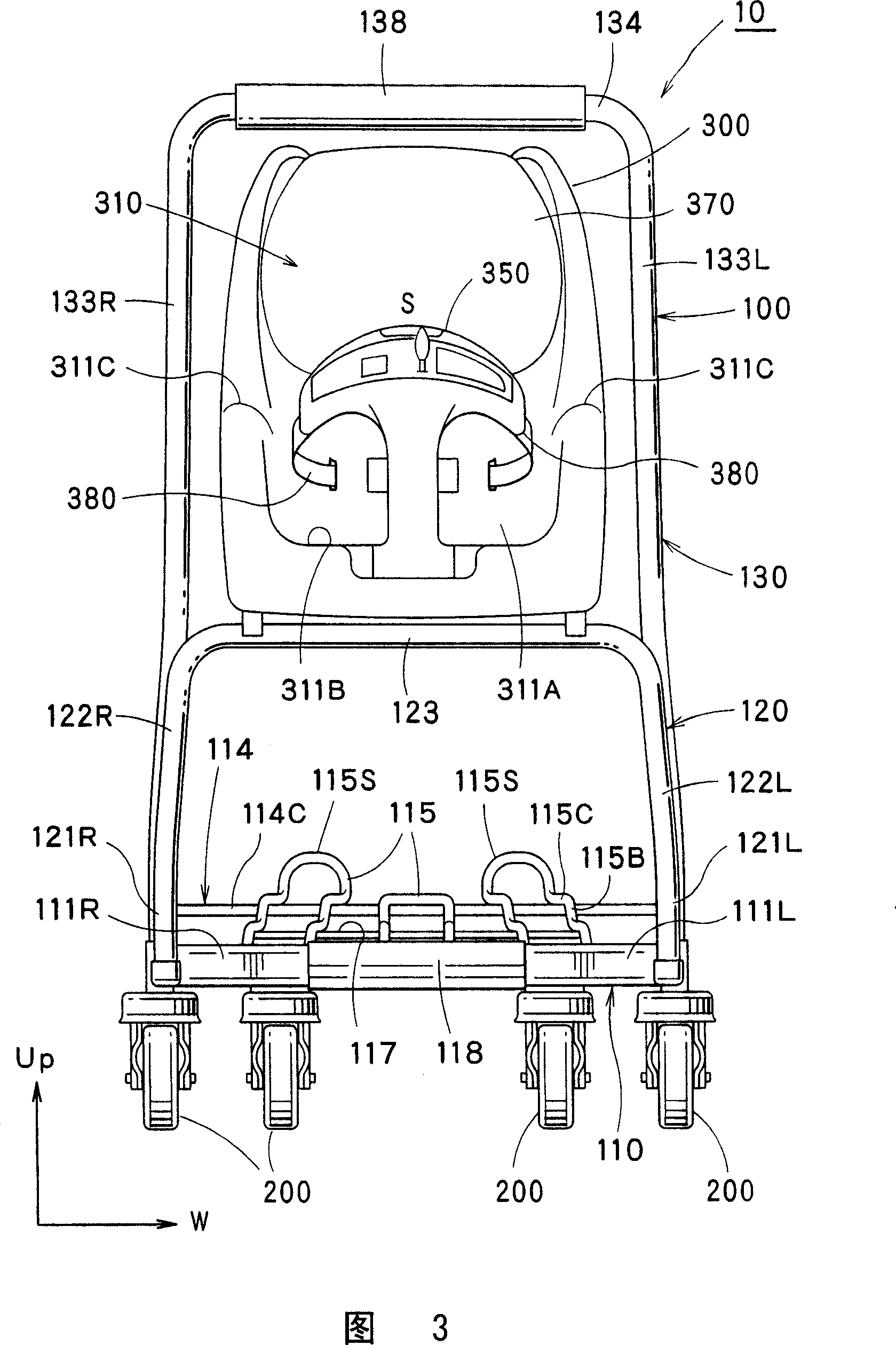

[0076] 1 is a front perspective view of a shopping cart 10 according to a first embodiment of the present invention, FIG. 2 is a rear perspective view of the shopping cart 10 of FIG. 1 , FIG. 3 is a front view of the shopping cart 10 of FIG. 1 , and FIG. Side view of a shopping cart 10. Fr in the figure represents the front of the shopping cart, Up represents the top, and W represents the width direction of the shopping cart. As shown in these figures, the shopping cart 10 includes a vehicle body 100 , traveling wheels 200 attached thereto, and a child seat 300 supported by the vehicle body 100 .

[0077] The main body 100 constituting the shopping cart 10 is constituted by a frame in which a plurality of steel pipes are bent and welded to each other. Specifically, the vehicle body 100 includes a base frame 110 , a seat support frame 120 erected from the base frame 110 that ...

no. 2 Embodiment approach

[0141] Next, a second embodiment of the present invention will be described with reference to FIGS. 14 to 18 .

[0142] The basic structure of the shopping cart 10 according to the first embodiment has been described above, but the shopping cart 10 according to this embodiment is characterized by the attachment structure of the head support 370 to the back portion 311A of the seat main body 310 . It will be described in detail below.

[0143] In this embodiment, the same reference numerals are assigned to the same parts as those in the first embodiment shown in FIGS. 1 to 11 , and detailed descriptions are omitted.

[0144] FIG. 14 is a perspective view showing the seat body 310 and the head support 370 illustrating the features of the present invention. FIG. 15 is an enlarged view of an X portion of the seat body 310 shown in FIG. 14 , and FIG. 16 is an enlarged view of a Y portion of the head support 370 shown in FIG. 14 . In the figure, Fr represents the front of the se...

no. 3 Embodiment approach

[0158] Next, a third embodiment of the present invention will be described with reference to FIGS. 19 to 29 .

[0159] In the first embodiment, the basic structure of the shopping cart 10 was described, but this embodiment is based on the support structure of the seat body 310 based on the support frame 140 formed by the cart body 100, and the seat body 310 can be rotated in stages. The aspect of the reclining adjustment mechanism which selectively adjusts the reclining angle is characteristic.

[0160] In this embodiment, the same reference numerals are assigned to the same parts as those in the first embodiment shown in FIGS. 1 to 11 , and detailed descriptions are omitted.

[0161] FIG. 19 shows a mounting structure for attaching the seat body 310 to the support frame 140 constituted by the vehicle body 100 and a reclining adjustment mechanism for stepwise adjusting the reclining angle by rotating the seat body 310 , showing the characteristic parts of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com