Rapid copper wire peeling and recycling device

A recycling device and fast technology, which is applied in the direction of cable installation device, cable installation, dismantling/armored cable equipment, etc., can solve the problems of low work efficiency, interruption of packing and recycling process, low efficiency of wire collection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] An embodiment of the present invention will be further explained below in conjunction with the accompanying drawings.

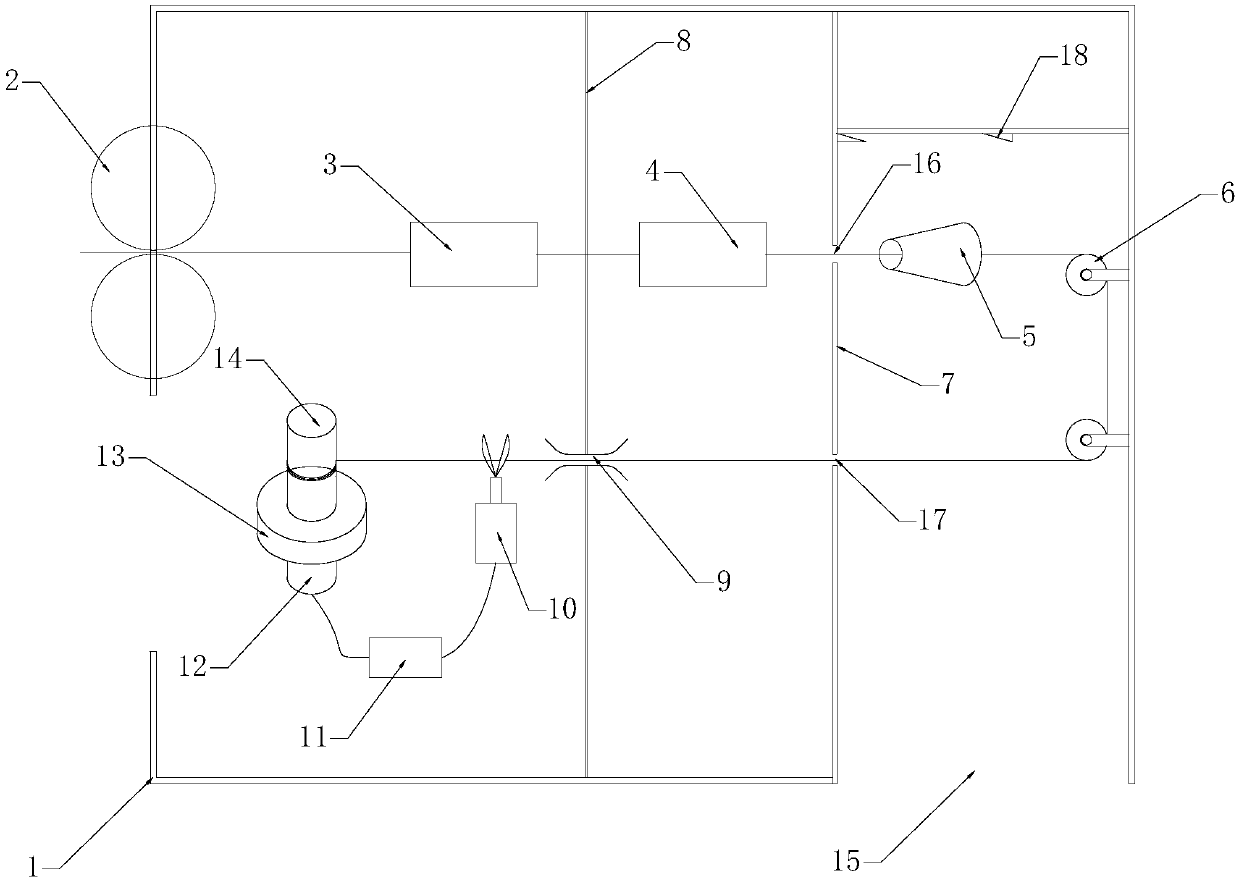

[0016] A copper wire rapid peeling recovery device, including a box body 1, an extrusion wheel 2, a heating box 3, a quenching box 4, a ring knife 5, a pulley 6, a barrier net 7, a sliding rod 8, a wire slider 9, and a pneumatic shear 10 , linkage controller 11, motor 12, torque protector 13 and take-up pulley 14.

[0017] Extrusion wheels 2 are arranged on the box body 1, and the gap between the extrusion wheels 2 is slightly smaller than the diameter of the recycled copper wire. The recovered copper wire is extruded from between the extrusion wheels 2 and becomes a straight line to enter the subsequent process.

[0018] A heating box 3 is arranged inside the box body 1, and the copper wire in a collimated state enters from one end of the heating box 3, and exits from the other end after being baked at a high temperature. Most of the recycled copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com