Movable altitude hot-line operation insulating bench

A live working and platform technology, applied in the direction of hoisting devices, etc., can solve the problems of inability to carry large equipment loads, limited load of insulating telescopic arms, etc., achieve safe and reliable live work, and improve the effect of carrying loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

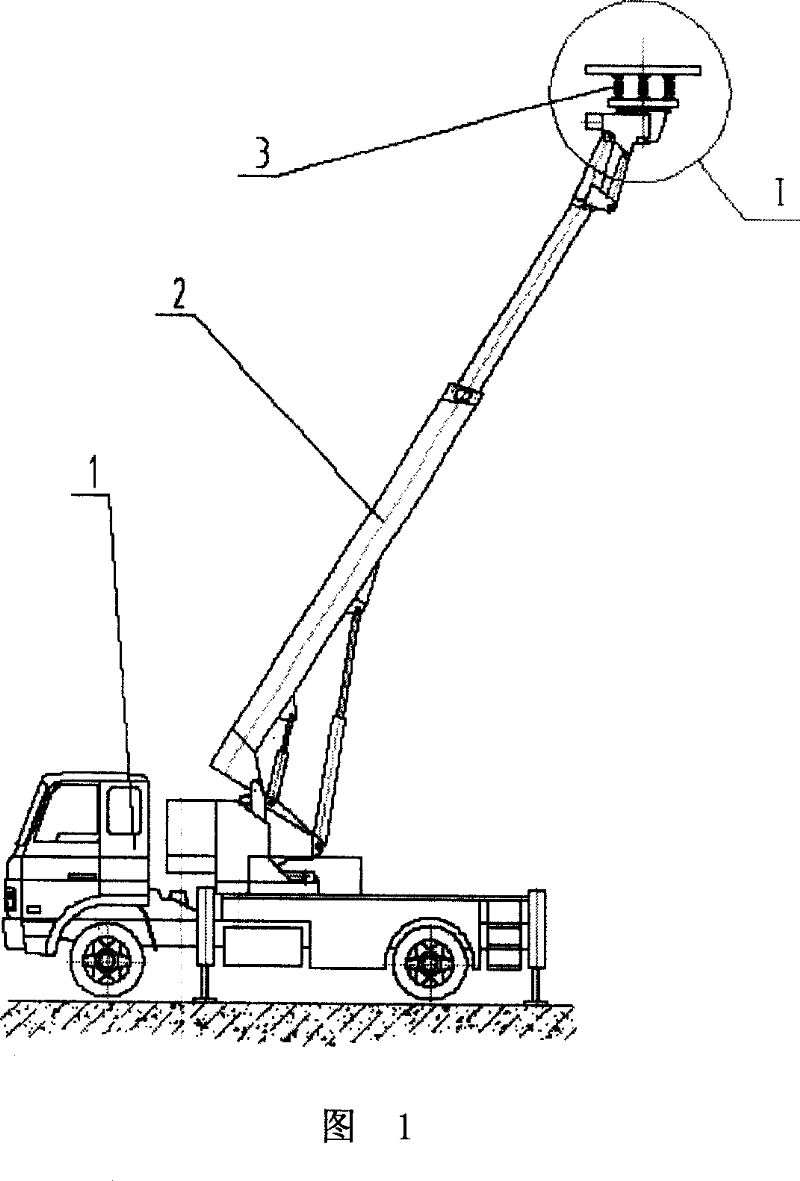

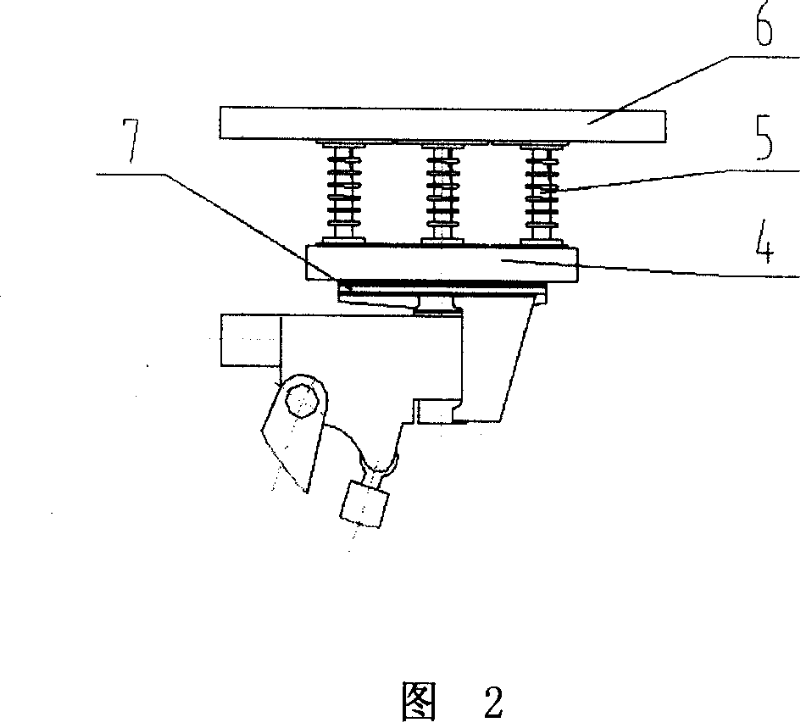

[0012] The present invention will be further described in conjunction with the accompanying drawings. First, according to the height of aerial work and the maximum load carried, purchase an engineering vehicle, determine the size and connection method of the top of the lifting arm on the engineering vehicle, design the insulating platform for live work, and determine the installation platform Size and the number and specifications of the insulator pillars, and then according to the size requirements, the metal profiles are blanked and welded into a frame structure; the steel plate with connection holes is welded on the connection between the frame of the installation platform and the insulator pillars; the frame of the connection platform is above At the joint with the insulator support, weld the steel plate with connection holes, and weld the steel plate connected to the connection plate 7 on the top of the lifting arm at the middle of the lower part, and finally fix the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com