Lens unit

A lens unit and lens technology, applied in optical components, optics, instruments, etc., can solve the problems of poor machinability of the first lens, increase of manufacturing cost, and lens unit not suitable for mass production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

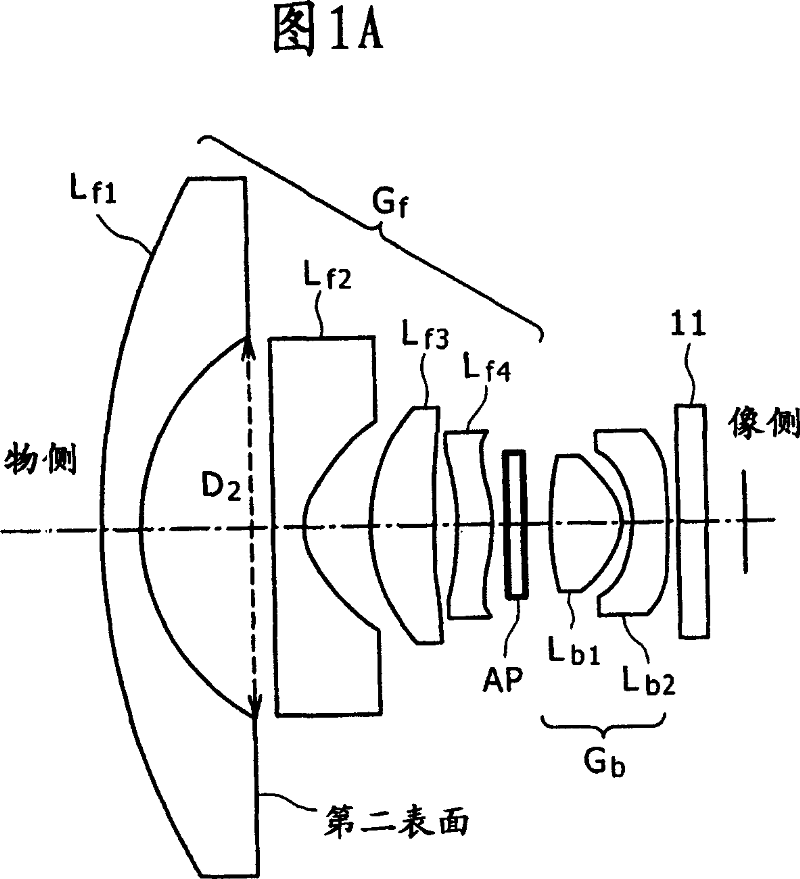

[0067] Embodiment 1 belongs to a lens unit according to an embodiment of the present invention, especially a lens unit according to a first mode of the present invention, more specifically, a fisheye lens unit. A conceptual diagram of a lens unit according to Embodiment 1 is shown in FIG. 1A. The lens unit in Embodiment 1 is a two-group six-lens lens unit including a front group G composed of lenses in order from the object side to the image side f , aperture AP and rear group G composed of lenses b . Front group G f In order from the object side to the image side include:

[0068] (A-1) First lens L having negative (having negative power) meniscus f1 ;

[0069] (A-2) Negative (having negative power) second lens L made of plastic and having an aspherical surface f2 ;

[0070] (A-3) Positive (having positive power) third lens L f3 ;as well as

[0071] (A-4) Positive (having positive power) fourth lens L f4 .

[0072] In addition, the latter group G b In order from t...

Embodiment 2

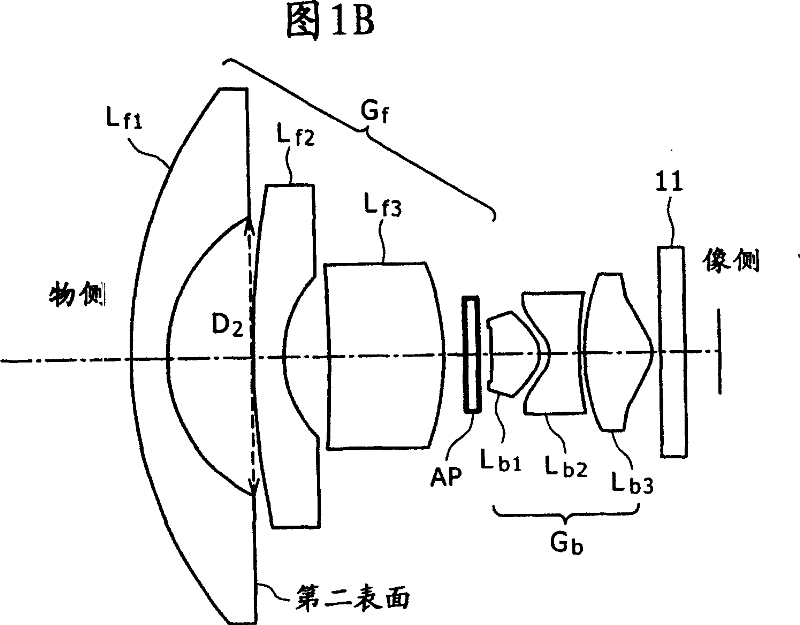

[0100] Embodiment 2 is a modification of Embodiment 1, which belongs to the lens unit according to the second mode of the present invention, specifically, a fisheye lens unit. A conceptual diagram of a lens unit in Example 2 is shown in FIG. 1B . The lens unit in Embodiment 2 is also a lens unit of 6 lenses in 2 groups, including a front group G composed of lenses in order from the object side to the image side f , the rear group G composed of aperture AP and lens b . Front group G f In order from the object side to the image side include:

[0101] (A-1) First lens L having negative (having negative power) meniscus f1 ;

[0102] (A-2) Negative (having negative power) second lens L made of plastic and having an aspherical surface f2 ;as well as

[0103] (A-3) Positive (having positive power) third lens L f3 . In addition, the latter group G b include:

[0104] (B-1) Positive (having positive power) first lens L b1 ;

[0105] (B-2) Negative (having negative power) s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com