Heat abstractor

A technology of heat dissipation device and radiator, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of heat dissipation efficiency, easy damage of heat pipes, and insufficient structure, so as to achieve the effect of enhancing stability and reducing stress burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

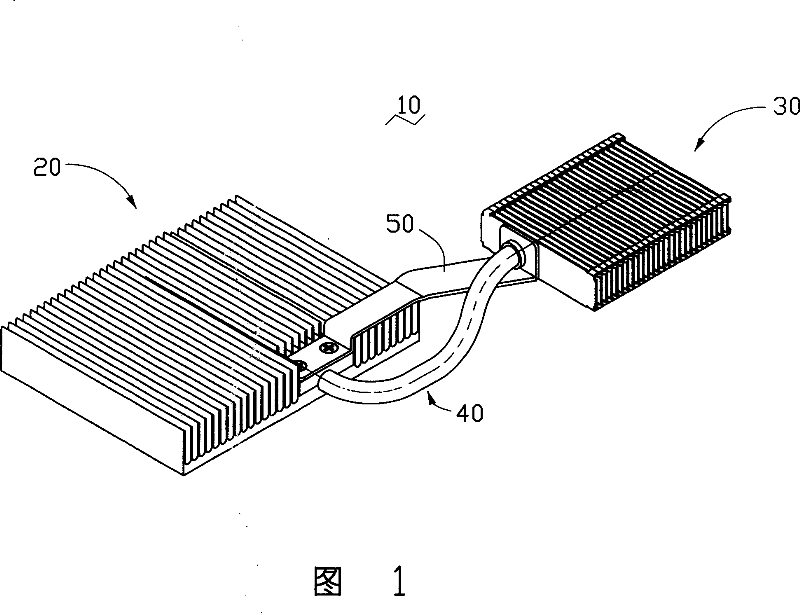

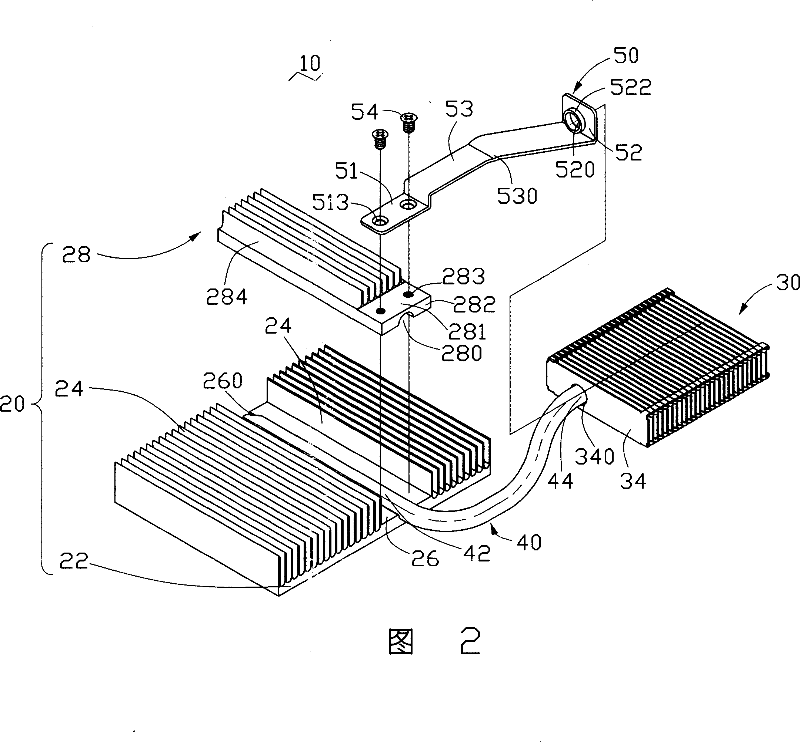

[0009] Referring to Fig. 1 and Fig. 2, the heat dissipation device 10 includes a first radiator 20, a second radiator 30, a heat pipe 40 and a protective frame 50 for conducting heat from the first radiator 20 to the second radiator 30 , the protective frame 50 is connected with the first heat sink 20 , the second heat sink 30 and the heat pipe 40 at the same time, so as to enhance the structural stability of the entire heat sink 10 .

[0010] The heat pipe 40 is curved and includes a heat absorbing portion 42 and a heat releasing portion 44 .

[0011] The first heat sink 20 includes a base 22 , two sets of cooling fins 24 extending upward from the base 22 and spaced apart from each other, and a separation block 28 installed between the two sets of cooling fins 24 . The two sets of cooling fins 24 on the first heat sink 20 are separated by a connecting portion 26 . A groove 260 is formed in the center of the top of the connecting portion 26 for accommodating the heat absorbing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com