Soft soil foundation high side pressure quick-discharging consolidation method

A soft soil foundation, drainage consolidation technology, applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as failure of foundation reinforcement, difficulty in dissipating pore water pressure, damage to the original structure of saturated soft soil, etc. Benefits and social benefits, shortening the construction period and improving the strength of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

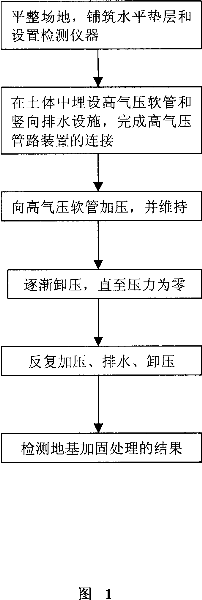

Image

Examples

Embodiment 1

[0008] This embodiment is a newly dredged fill of the beach, with an area of 13,000 square meters, 0.2m of the surface layer is sandy silt, and below it is 4.0m thick dredged fill muddy silty clay sandwiched with silt, with a water content of 59.3%. The force is less than 30KPa.

[0009] Using the process of the present invention to carry out foundation reinforcement treatment

[0010] (1) First level the site and lay a cushion on the surface. The cushion is silty sand with a thickness of 0.4m and the clay content is less than 5%. At the same time, pre-bury the piezometer and other test components.

[0011] (2) According to soil conditions and foundation reinforcement requirements, use a 0.2m diameter high-pressure hose, one end of the high-pressure hose is closed, the other end is open, and the closed end is buried in the soil. The high-pressure hoses are spaced at 1.5m, arranged in a square, and inserted into the soil to a depth of 5.0m. After the high-pressure hose is s...

Embodiment 2

[0018] This embodiment is a newly dredged fill of the beach, with an area of 10,000 square meters. The surface layer is 0.3m sandy silt, and the bottom is 5.0m thick dredged fill muddy silty clay sandwiched with silt, with a water content of 62.0 %, bearing capacity is less than 40KPa.

[0019] Using the process of the present invention to carry out foundation reinforcement treatment

[0020] (1) First level the site and lay a cushion on the surface. The cushion is 0.3m thick silty sand with a clay content of less than 5%. At the same time, pre-embed the piezometer and other test components.

[0021] (2) According to soil conditions and foundation reinforcement requirements, use a 0.2m diameter high-pressure hose, one end of the high-pressure hose is closed, the other end is open, and the closed end is buried in the soil. The high-pressure hoses are spaced at 2.0m, arranged in a square, and inserted into the soil to a depth of 6.0m. After the high-pressure hose is set, its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com