Engines connecting rod bushing

A technology for engine connecting rods and bushings, applied in the field of bushings, can solve problems such as difficulty in forming a stable oil film and low oil intake into the oil storage tank, and achieve the effects of stable oil film, enhanced reliability, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

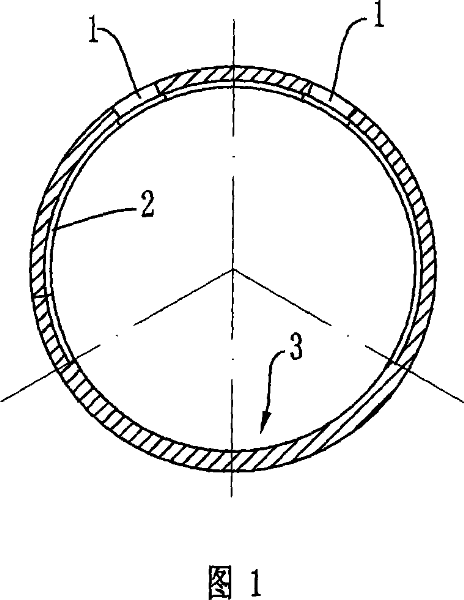

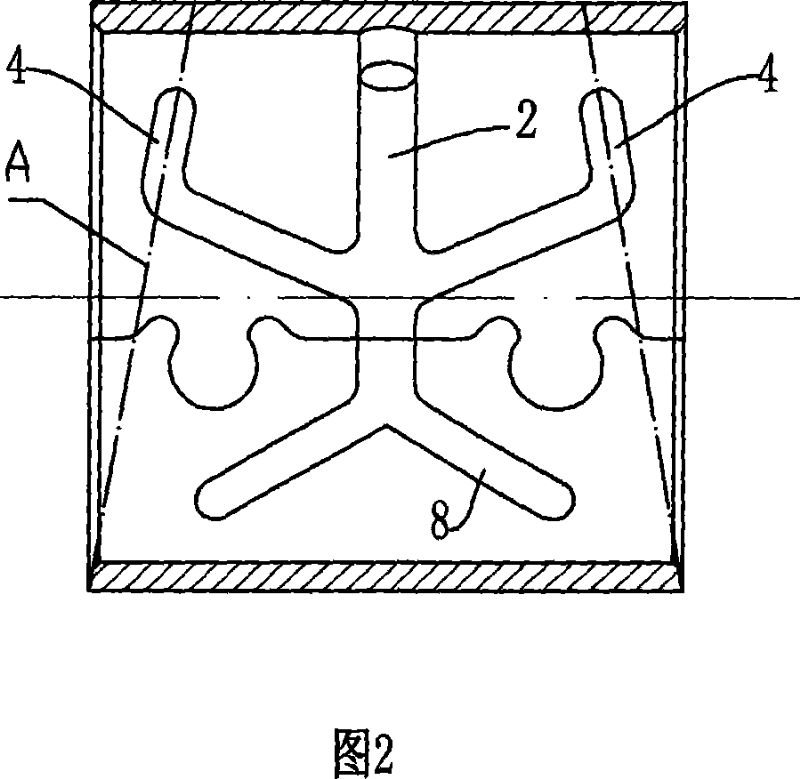

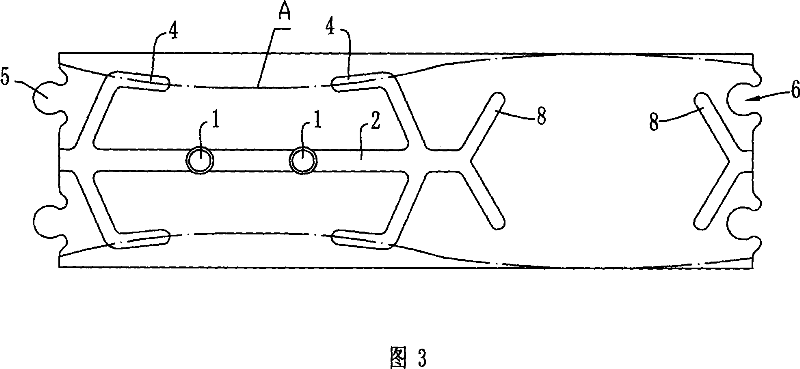

[0015] As shown in Figures 1 and 3 together, the engine connecting rod bushing has a cylindrical body, which includes a lower pressure bearing area 3 for bearing the pressure of the piston pin when the piston moves from the top dead center to the bottom dead center. The circumference angle of the lower pressure-bearing area 3 is about 110°~130°, and the upper pressure-bearing area is used to bear the pressure of the piston pin when the piston moves from the bottom dead center to the top dead center. The upper pressure-bearing area is provided with an oil hole 1, and there are two oil holes 1, and the two oil holes 1 are symmetrically arranged on both sides of the vertical plane of the upper pressure-bearing area. The inner wall of the body is provided with a main oil storage tank 2 extending in the circumferential direction. The main oil storage tank 2 is located in the axial middle of the body and communicates with the oil hole 1. The main oil storage tank 2 ends at the In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com