Actuator

A technology for actuators and motors, applied in power transmission/actuator features, electric components, transmissions, etc., can solve the problems of complex joint surfaces, increased number of parts, and difficulty in obtaining sealing, etc., to achieve small size The effects of simplification, easy assembly, and improved airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

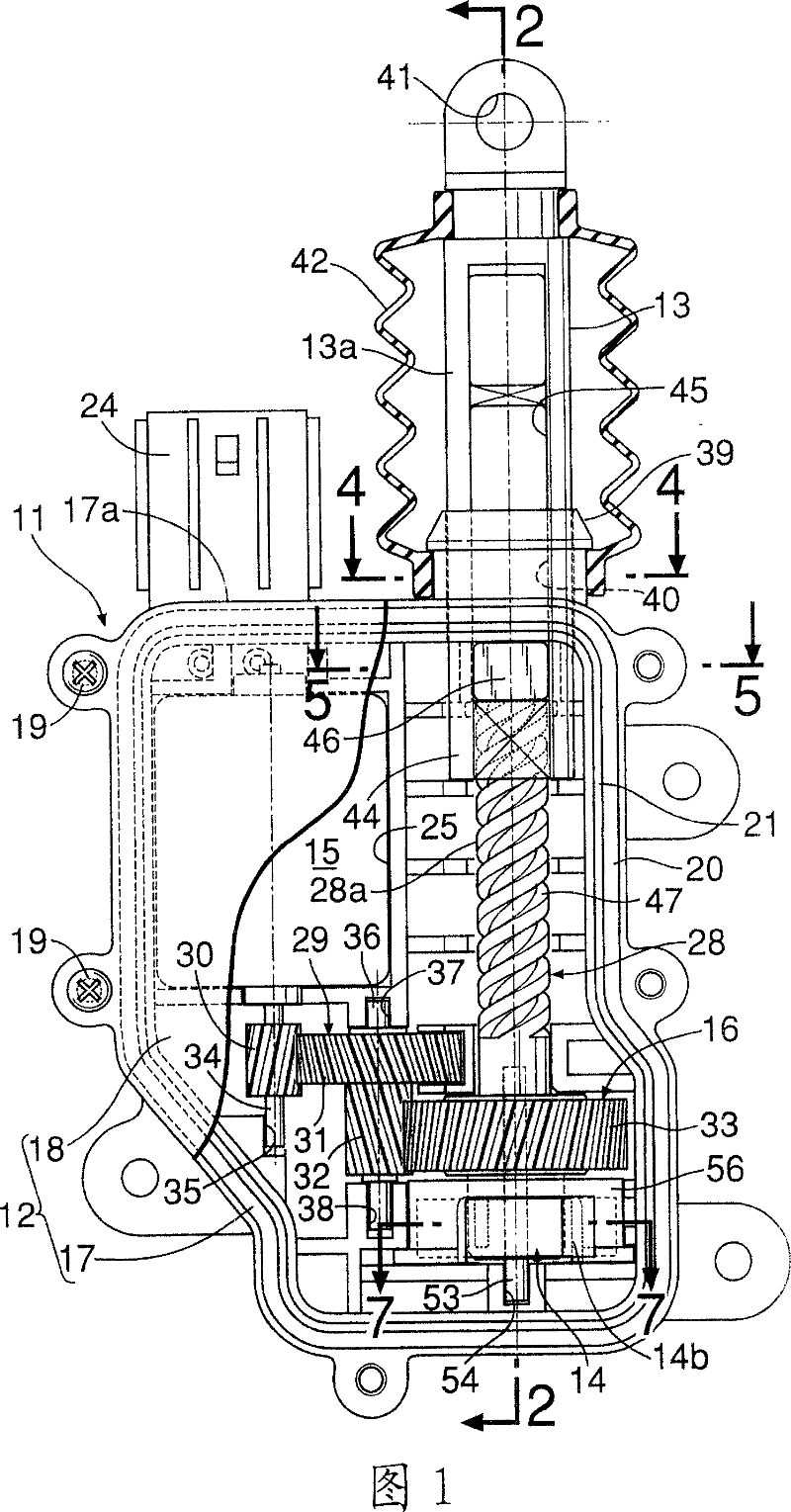

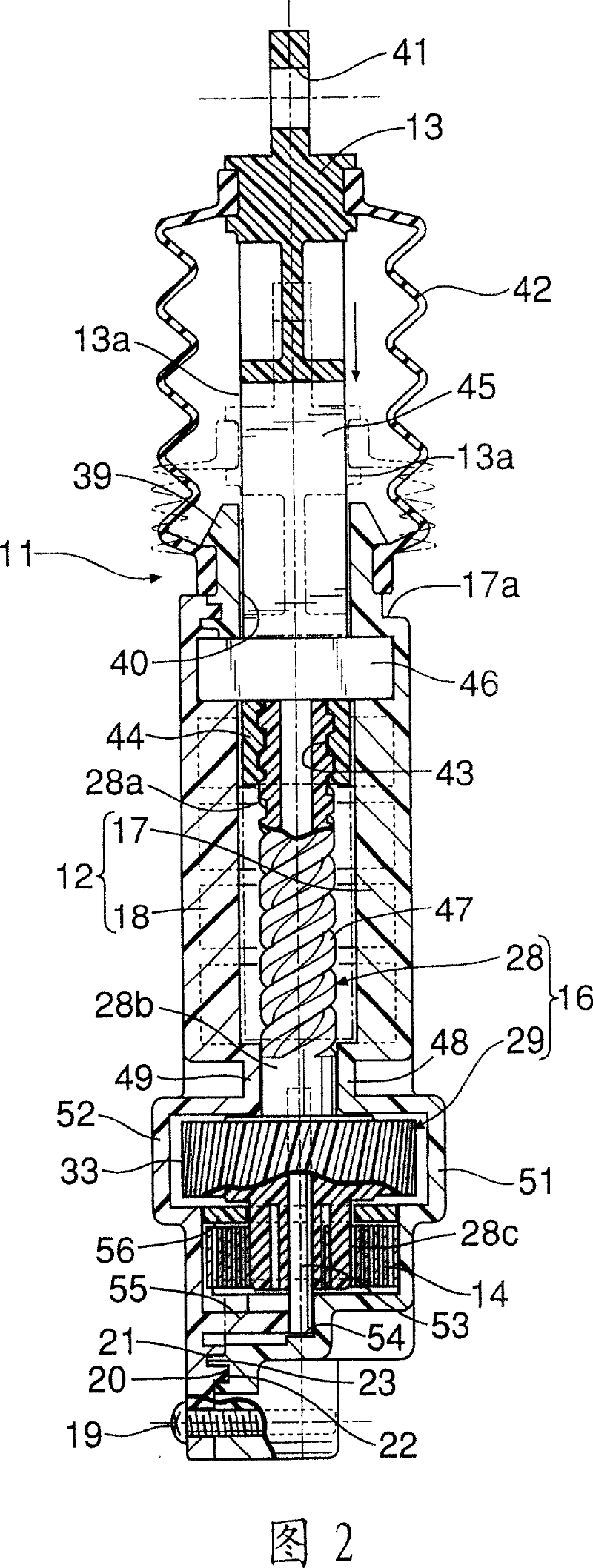

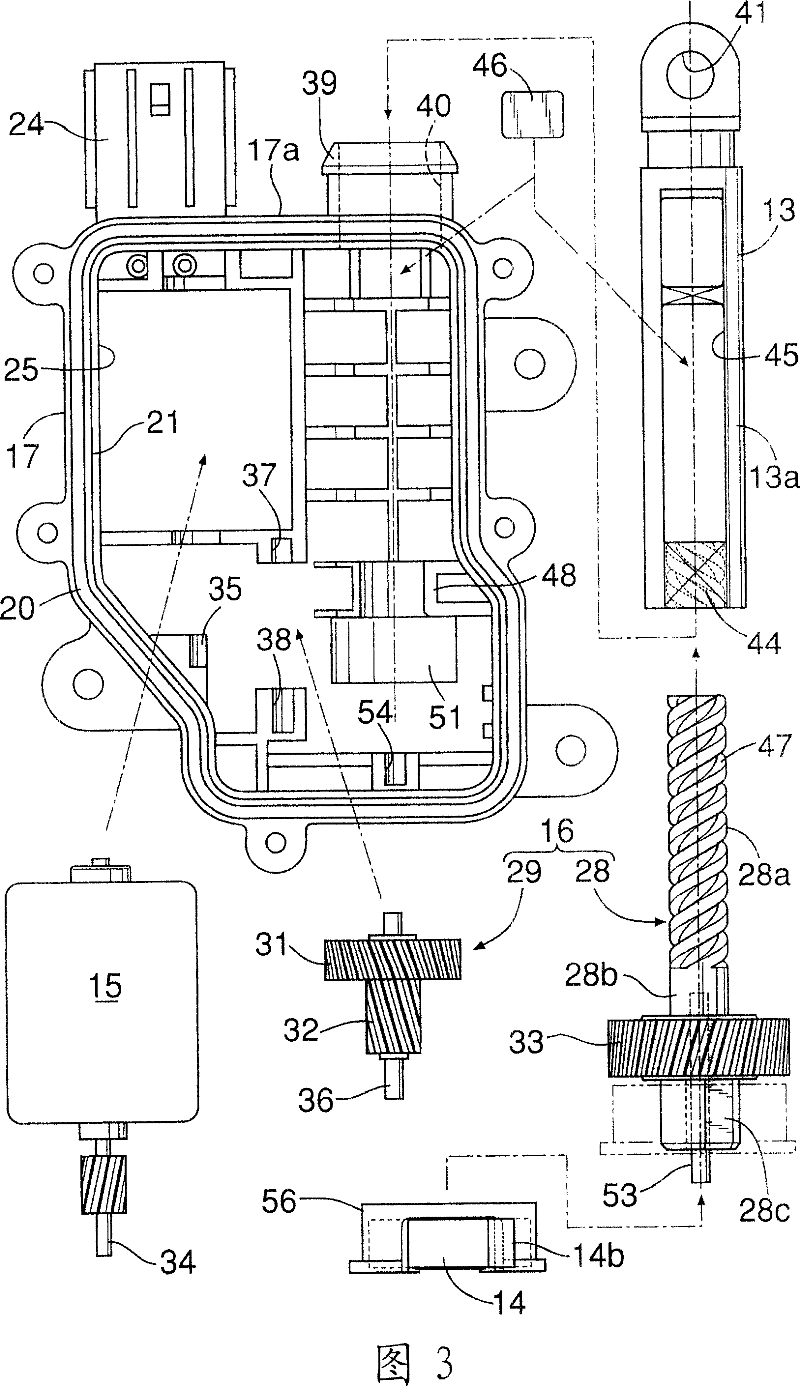

[0025] Fig. 1~Fig. 8 shows an embodiment of the present invention, and Fig. 1 is the partially sectioned front view of actuator, and Fig. 2 is the sectional view along line 2-2 in Fig. 1, and Fig. 3 is the exploded representation first half Figure 4 is a cross-sectional view along line 4-4 in Figure 1, Figure 5 is a cross-sectional view along line 5-5 in Figure 1, Figure 6 It is a perspective view of an output shaft and a stopper, FIG. 7 is a sectional view along line 7-7 in FIG. 1 , and FIG. 8 is an exploded perspective view of a scroll spring and a spring housing.

[0026] First in Fig. 1, the actuator 11, for example, exerts a driving force for releasing the locked state of the door lock device of the automobile, and the actuator 11 includes: a housing 12; an output shaft 13, which can reciprocate in the axial direction ground supported on the casing 12; the scroll spring 14, which applies force to the side that increases the protruding amount of the output shaft 13 from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com