Lever type electrical connector with slide members

A technology for sliding elements and electrical connectors, which is applied in the directions of connections, electrical components, and parts of connecting devices, and can solve problems such as difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

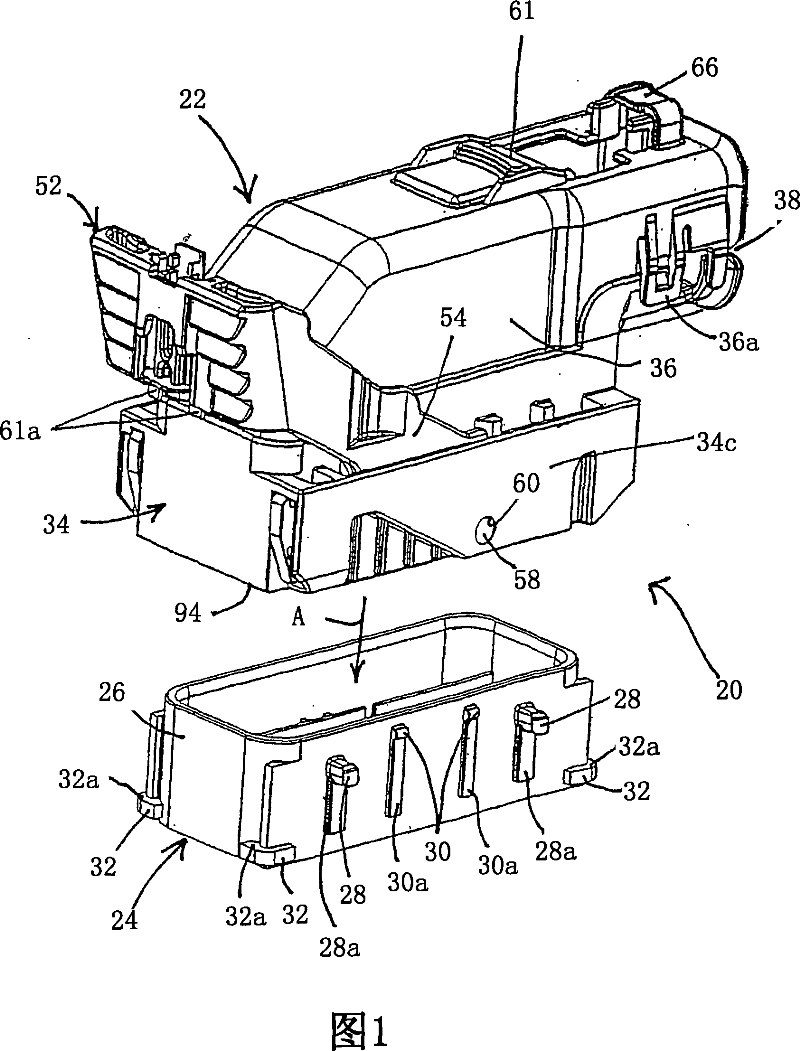

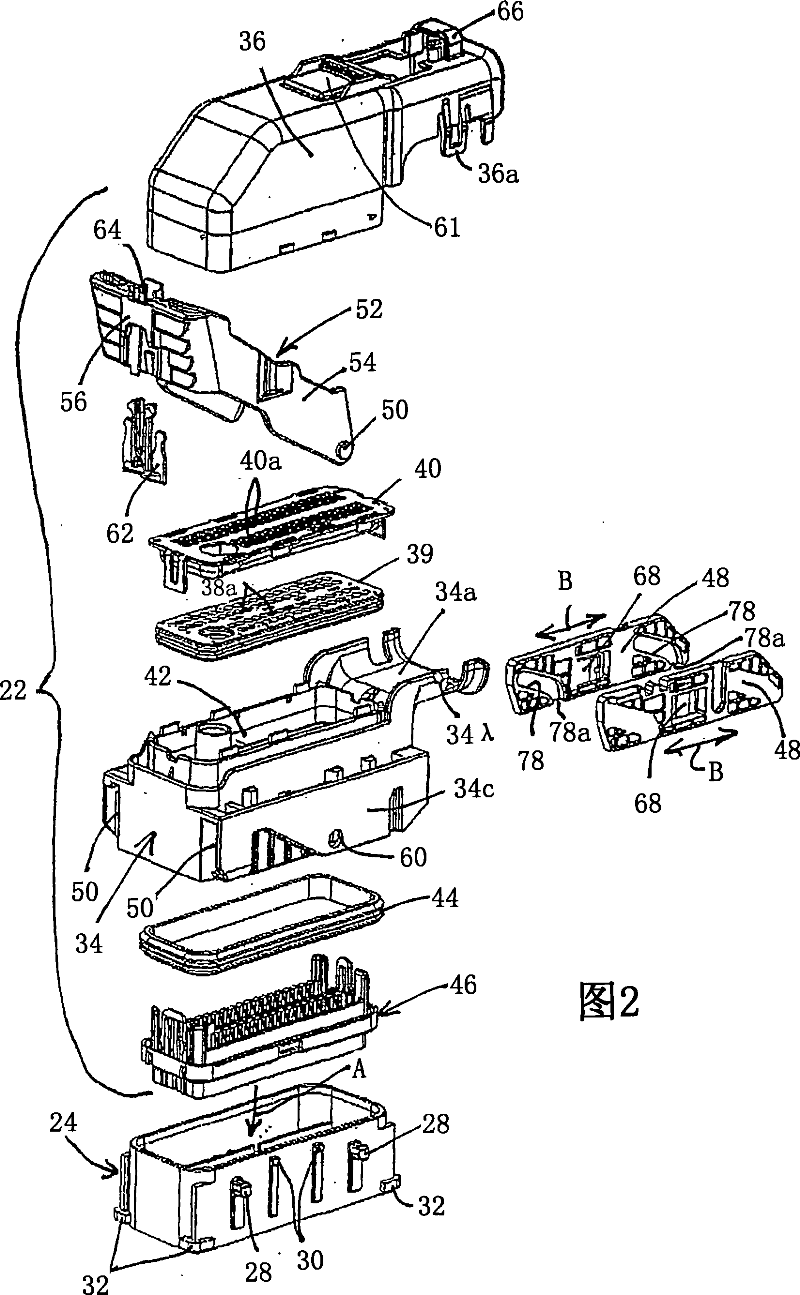

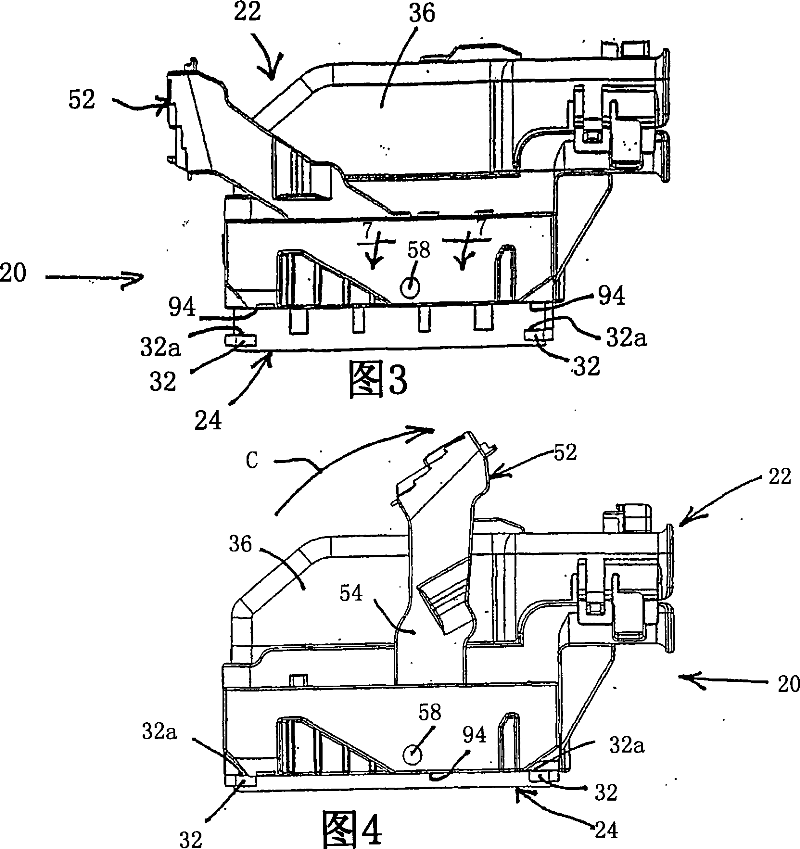

[0034] Referring to the drawings in detail, and first to FIGS. 1 and 2 , the present invention is embodied in a lever-type electrical connector assembly, generally designated 20 . The assembly includes a first (“actuator”) connector, generally designated 22 , and a second (“mating”) connector, generally designated 24 . As explained hereinafter, Figure 1 shows the connector alone; Figure 3 shows the pre-mated or initial position; Figure 4 shows the intermediate (interference) state; Figure 5 shows the fully mated position.

[0035] The mating connector 24 (FIGS. 1 and 2) is an end connector that may be mounted, for example, on an electronic module rack or frame located in an automobile. Therefore, the connector assembly is suitable for use in environments with high vibration and shock, although it can also be used in other situations. In practice, this assembly has been used directly on the motor frame of a vehicle, where vibrations and shocks are severe.

[0036] The mating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com