Fan, motor and their bearing structure

A technology of bearings and motors, which is applied in the direction of bearing components, shafts and bearings, casings/covers/supports, etc., can solve problems such as limited effects, and achieve the effect of preventing oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

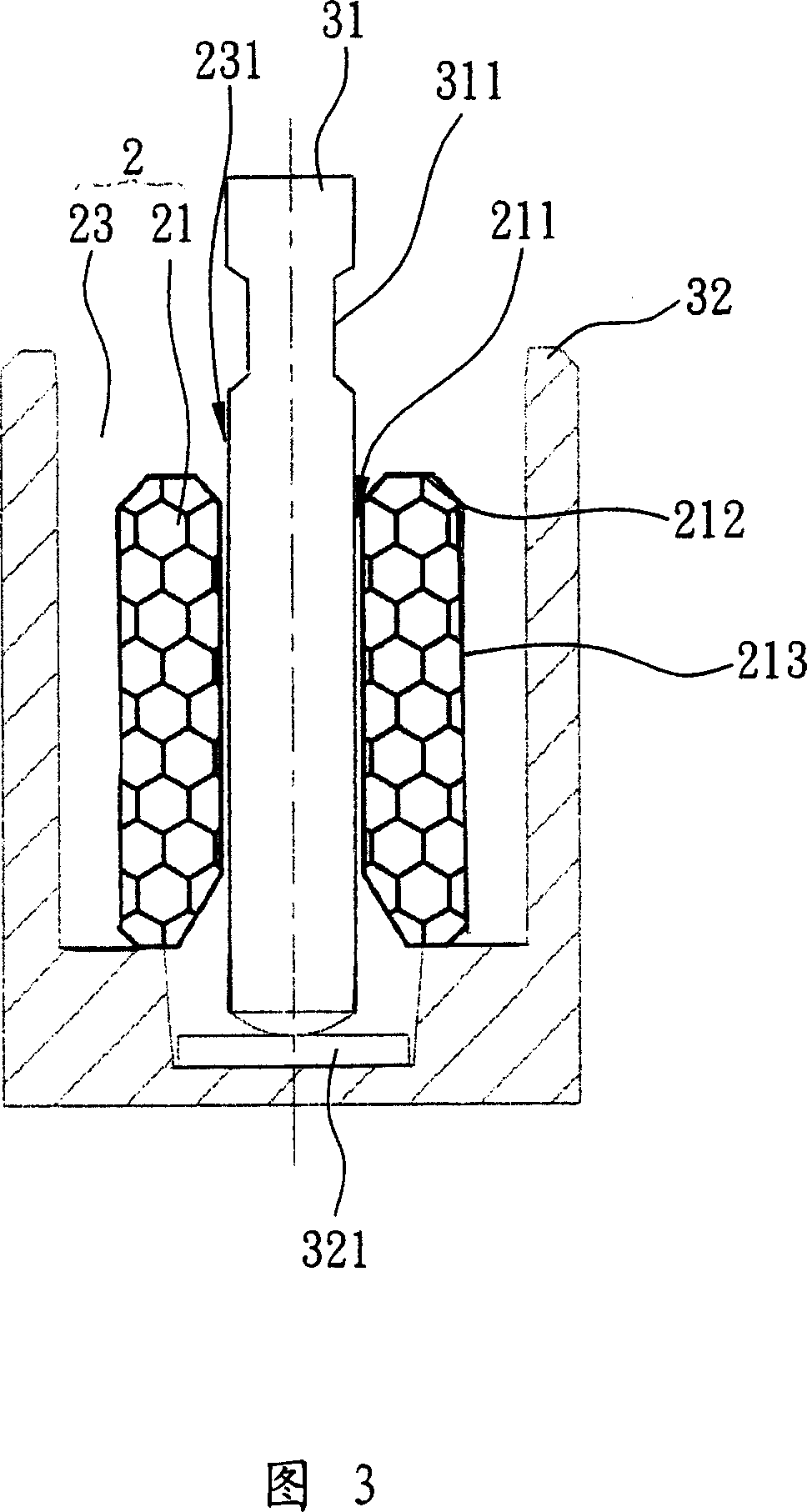

[0057] A fan, a motor and its bearing structure according to a preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components will be denoted by the same reference numerals.

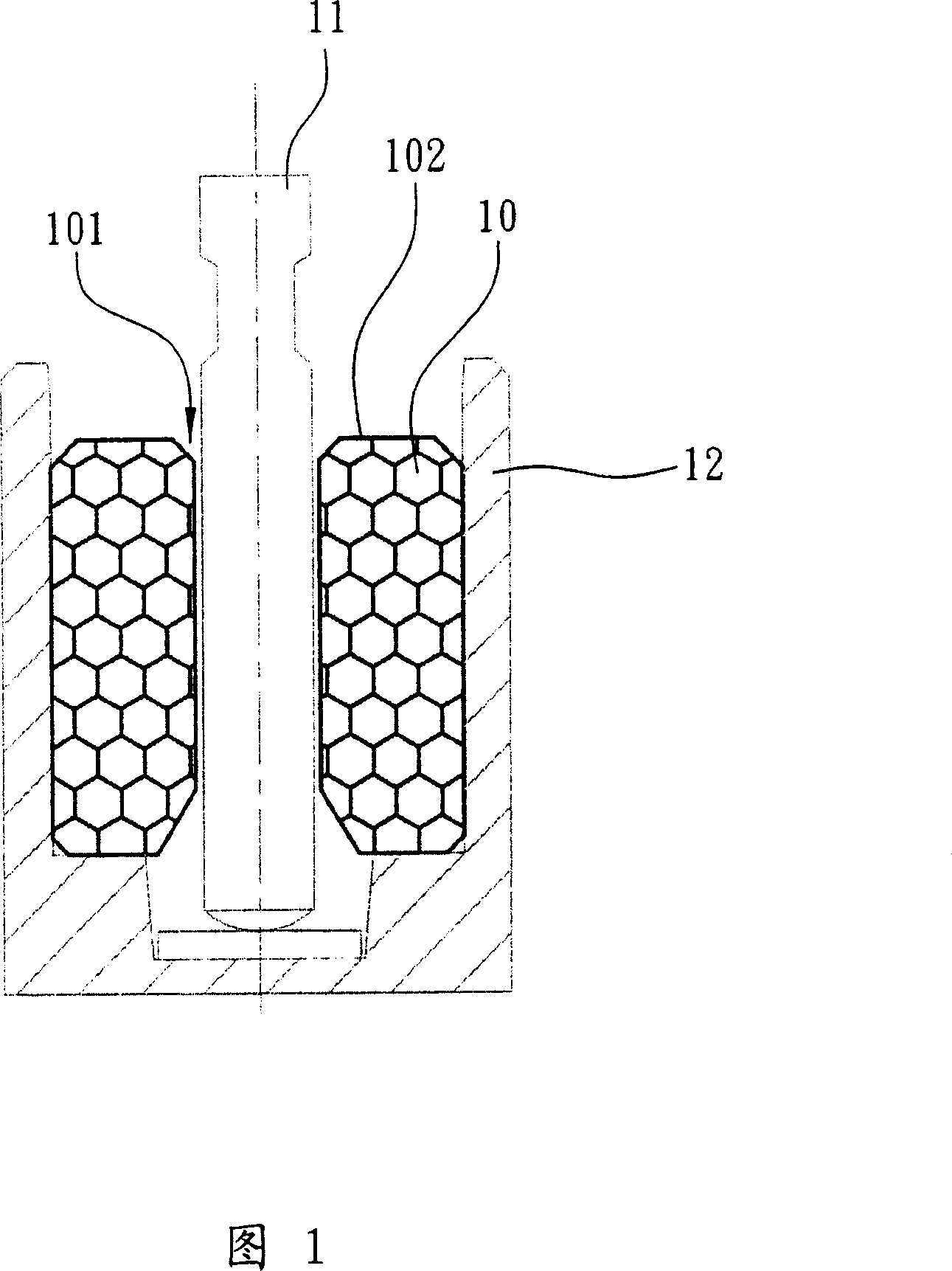

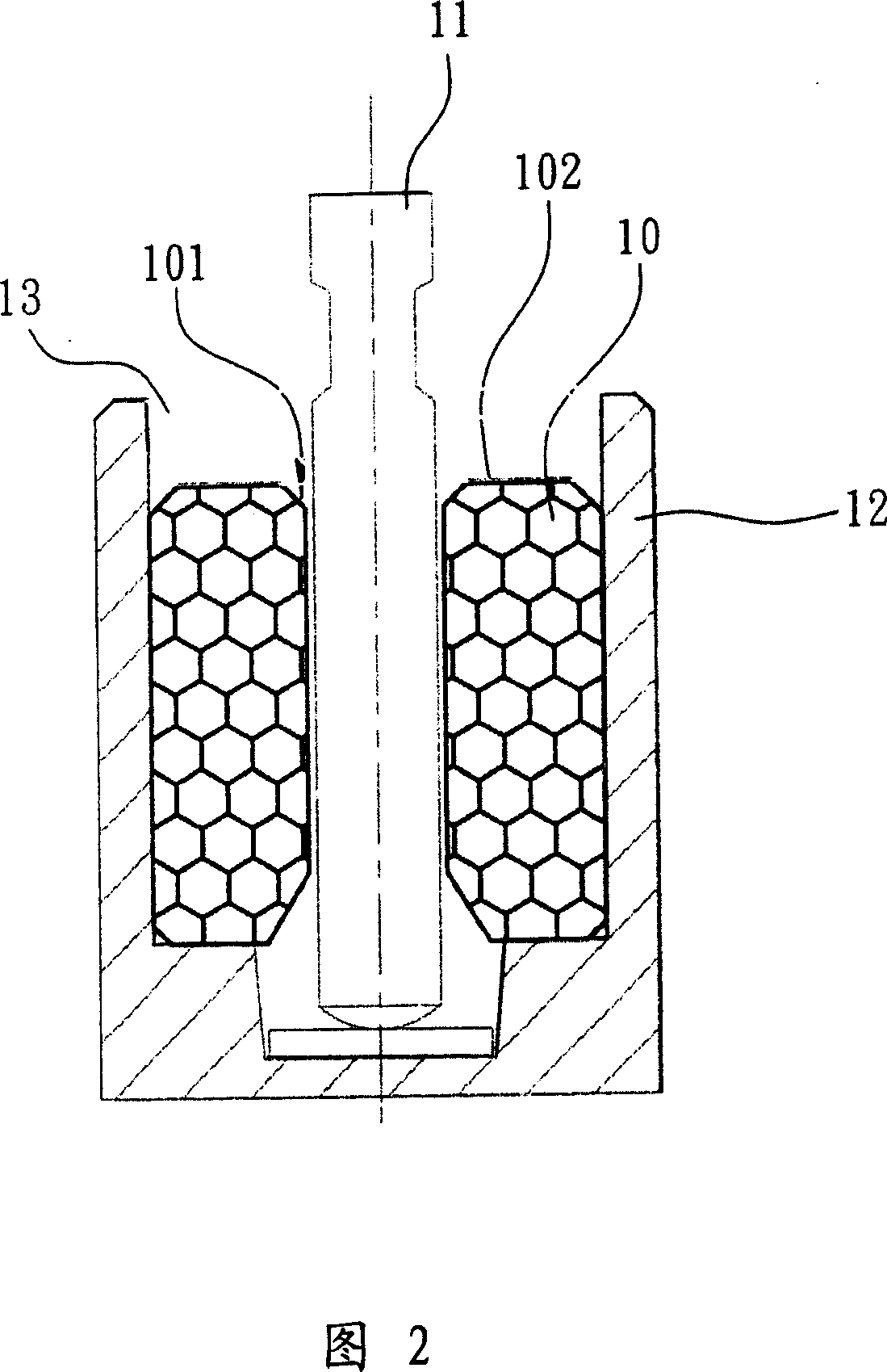

[0058] See Figure 3. As shown in FIG. 3 , the bearing structure 2 of the first preferred embodiment of the present invention cooperates with the rotating shaft 31 , and the bearing structure 2 is arranged in the shaft tube 32 . When the bearing structure 2 is applied to a motor, the rotating shaft 31 can be the rotating shaft of the rotor structure in the motor, and the shaft tube 32 can be the shaft tube of the stator structure in the motor.

[0059] In this embodiment, the shaft tube 32 is integrally formed, that is, the shaft tube 32 is a single body. In addition, the bottom of the shaft tube 32 has a wear-resistant structure 321 (such as a wear-resistant sheet). Of course, in other embodiments, the shaft tube 32 can also be a sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com