Manufacturing method for LED module

A technology for light-emitting diodes and a manufacturing method, which is applied in the manufacturing of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of easy falling off of identification materials, easy falling off of marking stickers, and low cost of labeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

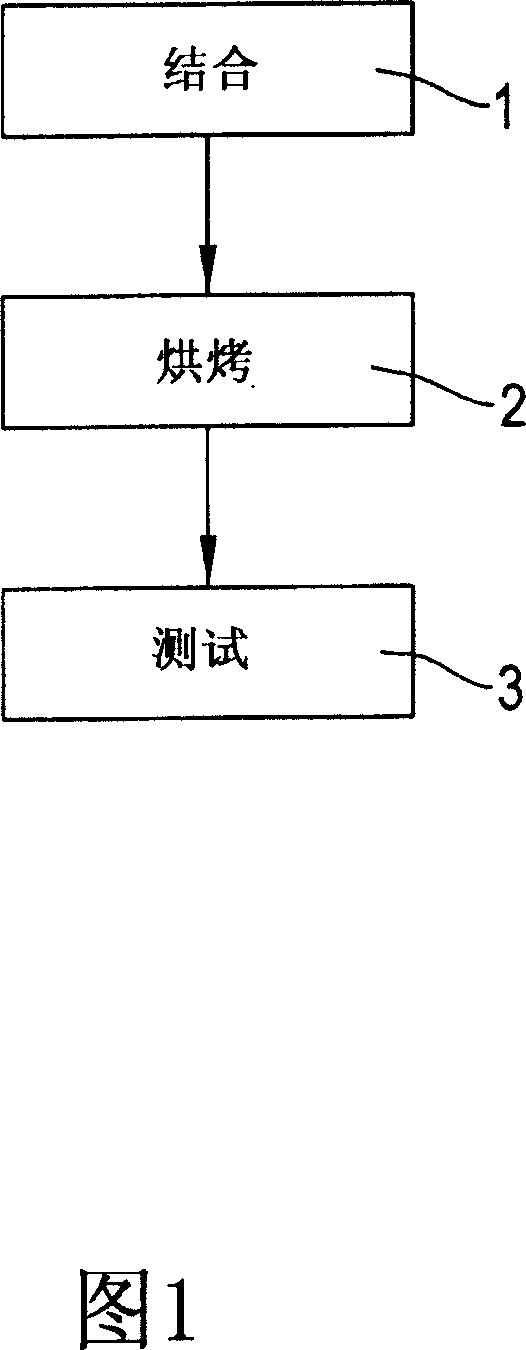

[0019] Referring to Fig. 1, the process of the present invention comprises the following steps:

[0020] 1. Combination: The electronic components are combined on the circuit board, and the identification resistor is combined on the side of the light-emitting diode.

[0021] 2. Baking: Place the completed combined circuit board into a reflow oven for baking.

[0022] 3. Test: test the baked circuit board.

[0023] In actual manufacturing, there are two ways for the circuit board to be combined with electronic components, one is the way of plugging in DIP (Dual In-Line Package), and the other is the way of applying solder paste on the circuit board to make the circuit board contacts There is solder on the surface, and the electronic components are combined with the circuit board by using the surface mount technology SMT (Surface Mount Technology). Put it into a reflow oven and bake at high temperature. The baked circuit board is then subjected to a lighting test, a burn-in te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com