Spindle drive of accurate doublefaced polisher

A double-sided polishing machine and spindle drive technology, applied in the field of polishing machines, can solve the problems of inability to realize stepless speed regulation, poor processing stability, and low polishing efficiency, and achieve compact structure, small impact impact, and improved polishing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

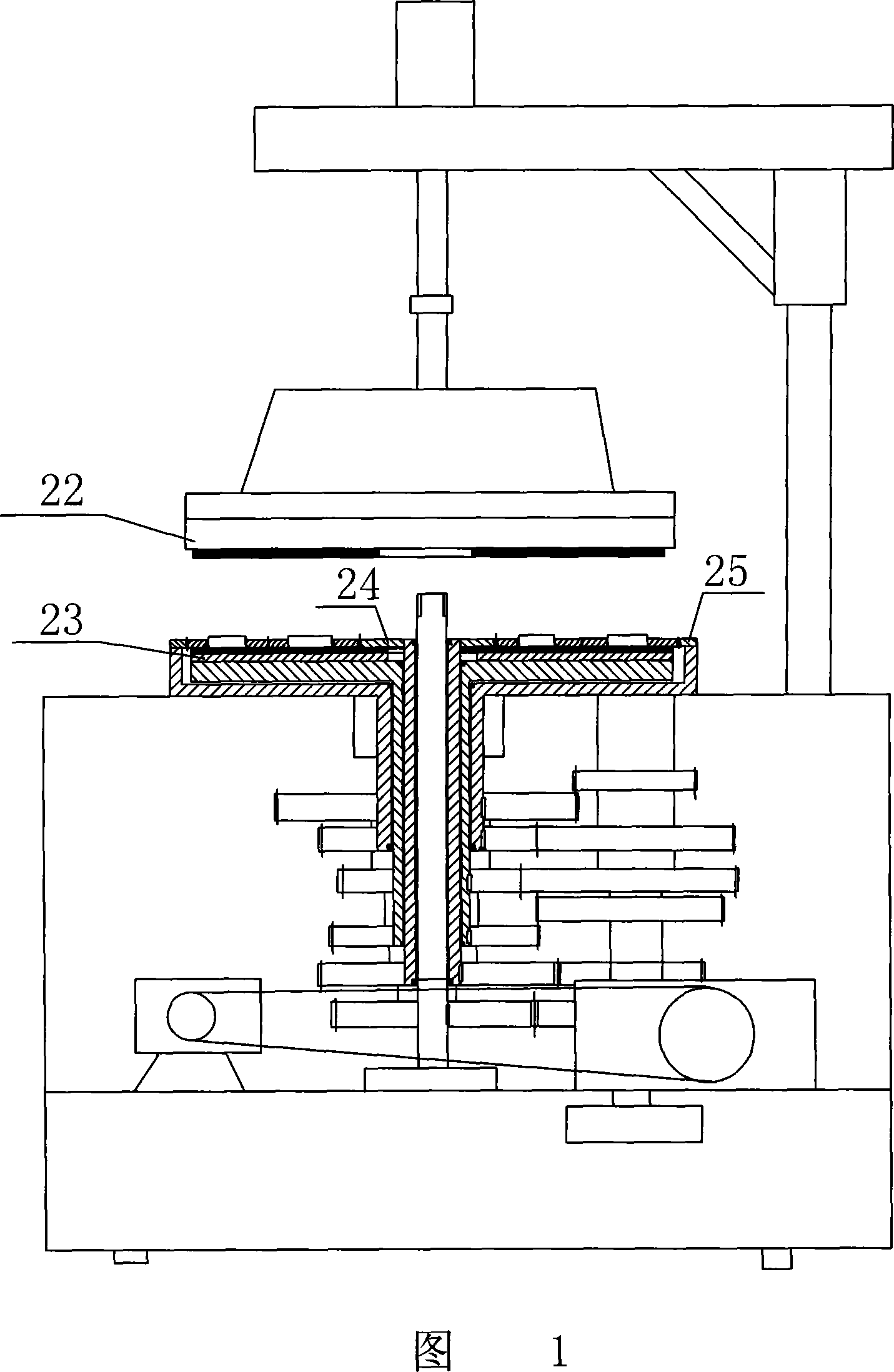

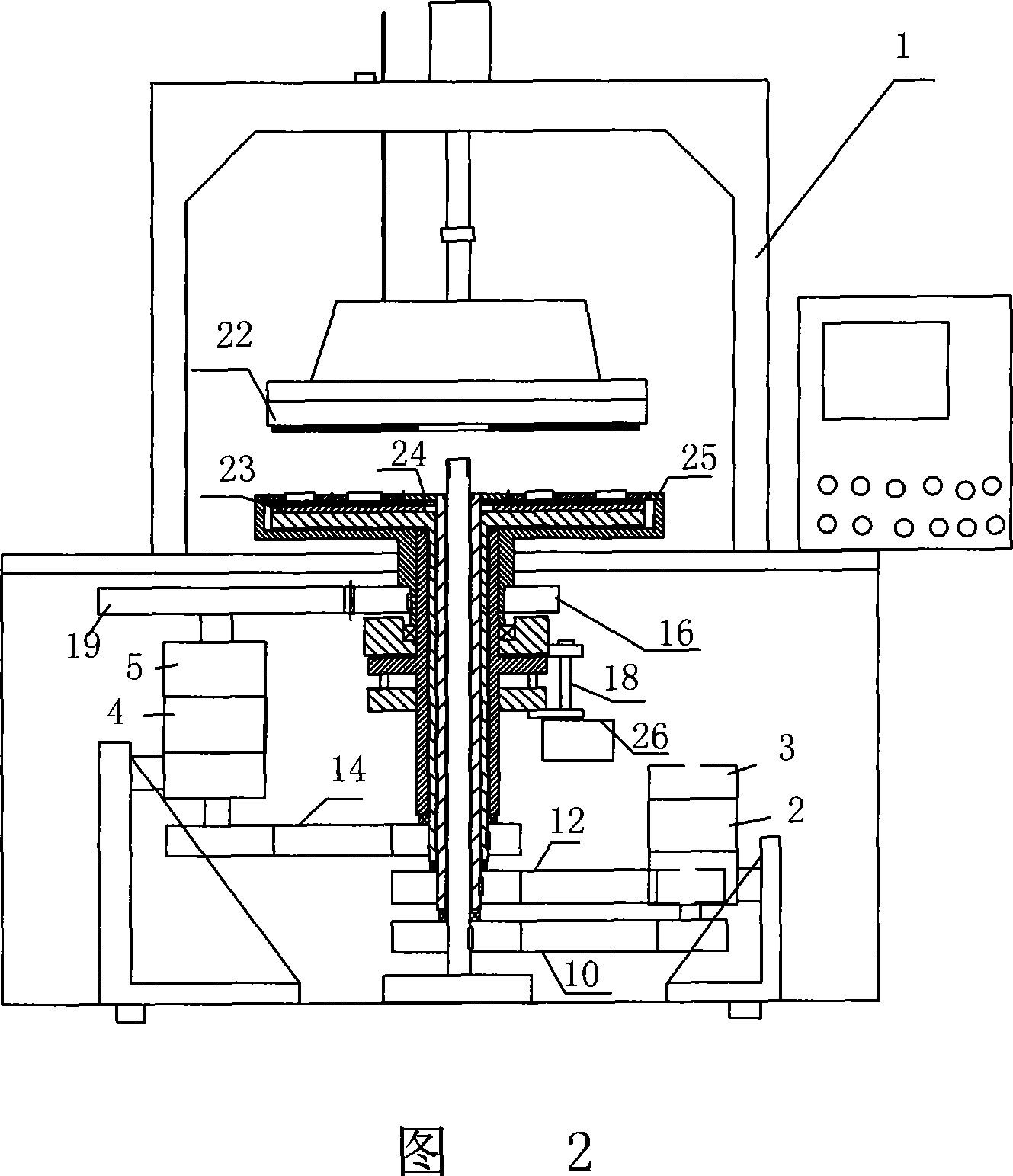

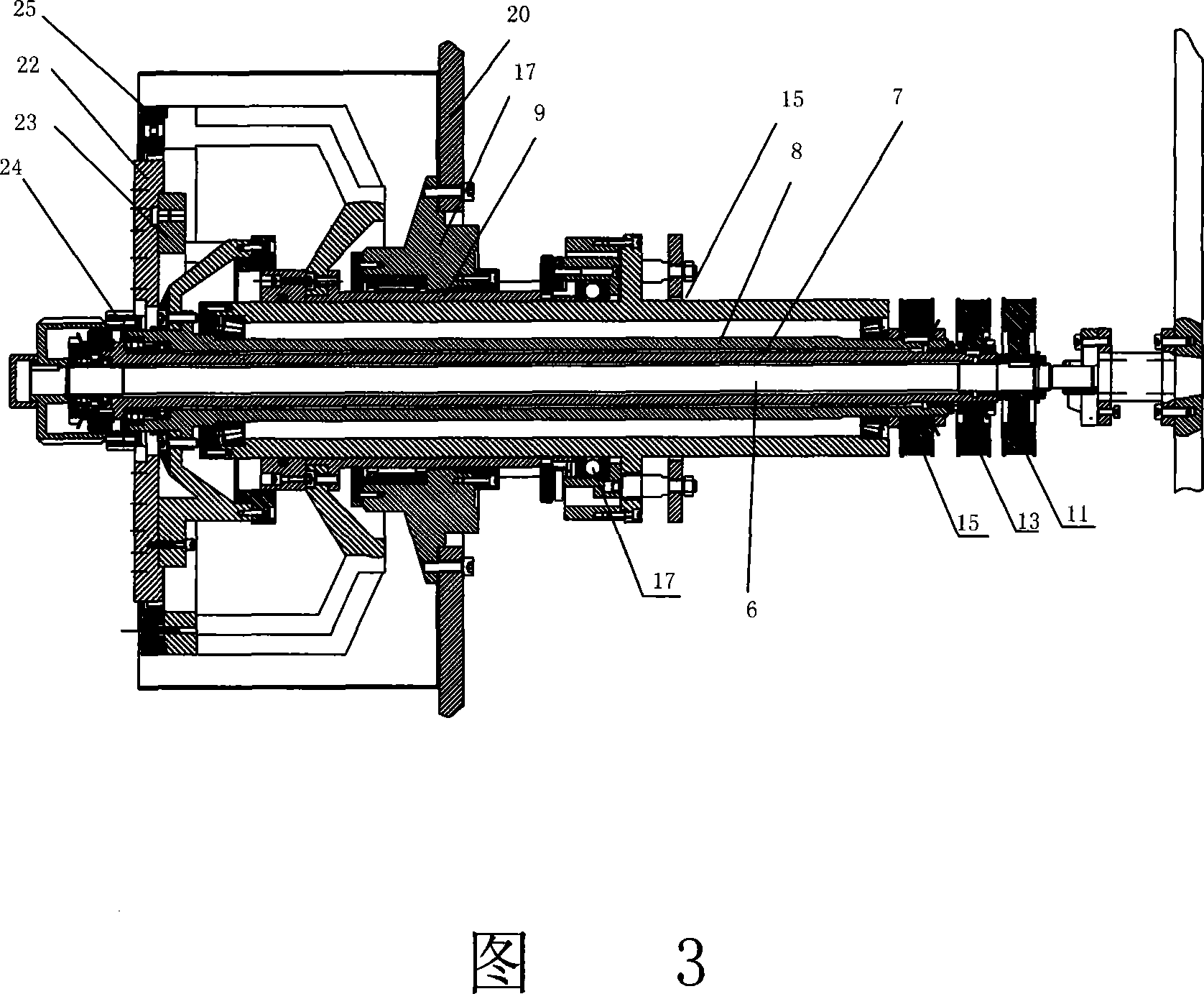

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] Referring to Fig. 2 and Fig. 3, a main shaft transmission mechanism of a precision double-sided polishing machine includes a frame 1, four frequency conversion motors, a long shaft 6 for driving the upper polishing disc to rotate, a small shaft 7 for driving the inner ring gear to rotate, and a drive The middle shaft 8 that rotates the lower polishing disc and the large shaft 9 that drives the outer ring gear to rotate, the output shaft of the first variable frequency motor 2 is connected to the first transmission belt 10 to drive the long shaft 6, and the bottom end of the long shaft 6 is connected to the long shaft bearing 11. The long shaft bearing 11 is installed on the frame 1; the output shaft of the second frequency conversion motor 3 is connected with the second transmission belt 12 to drive the small shaft 7, and the bottom end of the small shaft 7 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com